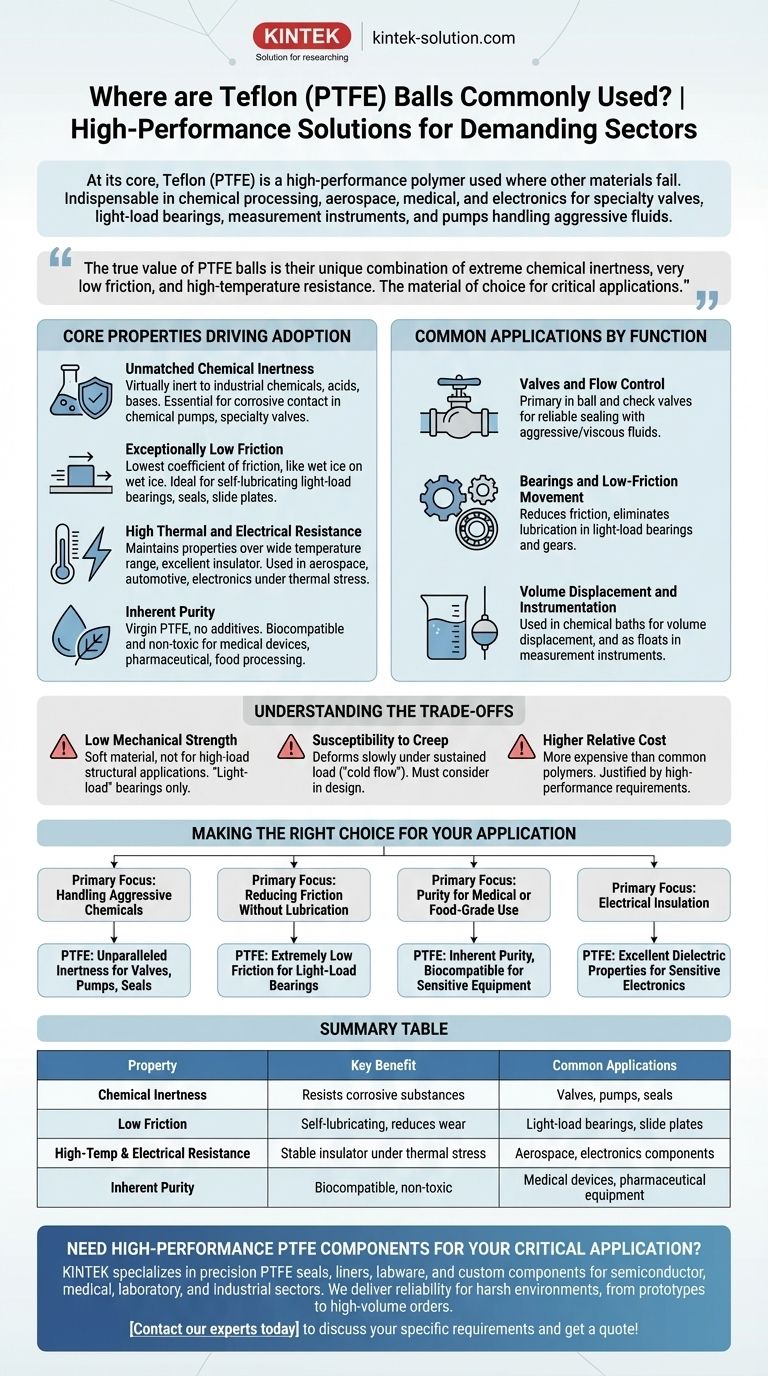

At its core, Teflon (PTFE) is a high-performance polymer used where other materials fail. Its balls are indispensable across a wide range of demanding sectors, including chemical processing, aerospace, medical, and electronics. They are commonly found in applications like specialty valves, light-load bearings, measurement instruments, and pumps handling aggressive fluids.

The true value of PTFE balls is not just one single property, but their unique combination of extreme chemical inertness, very low friction, and high-temperature resistance. This makes them the material of choice for critical applications where performance and reliability under harsh conditions are non-negotiable.

The Core Properties Driving PTFE Adoption

To understand where PTFE balls are used, you must first understand why they are chosen. Their widespread adoption is driven by a few key material characteristics that are difficult to find in other polymers.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with the vast majority of industrial chemicals, acids, and bases. This makes it essential for components that are in direct contact with corrosive substances.

This property is why PTFE balls are standard in chemical handling pumps, specialty valves, and any equipment used in chemical and steel processing.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. It provides a naturally "slippery" surface that requires no external lubrication.

This self-lubricating nature is ideal for light-load ball bearings, seals, and slide plates where minimizing friction and wear is critical.

High Thermal and Electrical Resistance

PTFE maintains its properties across a wide temperature range and is an outstanding electrical insulator. It does not absorb water and has high dielectric strength.

These characteristics make it a reliable choice for components in the aerospace, automotive, and electronics industries, where parts must perform under thermal stress and provide reliable insulation.

Inherent Purity

Virgin PTFE is an extremely pure polymer, containing no plasticizers, lubricants, or stabilizers. This purity makes it suitable for sensitive applications where contamination is a concern.

You will find PTFE balls in medical devices, pharmaceutical manufacturing, and food processing equipment because of their inherent biocompatibility and non-toxic nature.

Common Applications by Function

While the industries are diverse, the functions PTFE balls serve can be grouped into a few key categories.

Valves and Flow Control

Due to their chemical resistance and low-friction seating, PTFE balls are a primary component in ball valves and check valves. They create a reliable seal and can operate smoothly even with aggressive or viscous fluids.

Bearings and Low-Friction Movement

In applications that do not involve heavy loads, PTFE balls are used in bearings and gears to reduce friction and eliminate the need for maintenance and lubrication.

Volume Displacement and Instrumentation

In chemical baths, PTFE balls are used for volume displacement to reduce the surface area exposed to air, minimizing evaporation and heat loss. Their consistent density also makes them useful as floats in certain measurement instruments.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging the limitations of PTFE to prevent misapplication.

Low Mechanical Strength

PTFE is a relatively soft material. It is not suitable for high-load or high-pressure structural applications. This is why you see it specified for "light-load" bearings, as it can deform under significant mechanical stress.

Susceptibility to Creep

Under a sustained load, PTFE can slowly deform over time, a phenomenon known as "creep" or "cold flow." This must be considered in the design of components that will be under constant pressure.

Higher Relative Cost

Compared to common polymers like nylon or polypropylene, PTFE is more expensive. Its use is typically justified by performance requirements that other, cheaper materials simply cannot meet.

Making the Right Choice for Your Application

Selecting the right material depends entirely on your primary challenge.

- If your primary focus is handling aggressive chemicals: PTFE's unparalleled chemical inertness makes it the default choice for valves, pumps, and seals in corrosive environments.

- If your primary focus is reducing friction without lubrication: The extremely low friction coefficient of PTFE is ideal for light-load bearings and self-lubricating slide components.

- If your primary focus is purity for medical or food-grade use: The inherent purity and biocompatibility of PTFE make it a safe and reliable option for sensitive equipment.

- If your primary focus is electrical insulation: PTFE's excellent dielectric properties are critical for components in sensitive electronic applications where signal integrity is key.

Ultimately, choosing PTFE is a decision to prioritize performance and longevity in environments that would cause most other materials to fail.

Summary Table:

| Property | Key Benefit | Common Applications |

|---|---|---|

| Chemical Inertness | Resists corrosive substances | Valves, pumps, seals |

| Low Friction | Self-lubricating, reduces wear | Light-load bearings, slide plates |

| High-Temp & Electrical Resistance | Stable insulator under thermal stress | Aerospace, electronics components |

| Inherent Purity | Biocompatible, non-toxic | Medical devices, pharmaceutical equipment |

Need high-performance PTFE components for your critical application? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. We deliver the reliability your harsh environments demand, from prototypes to high-volume orders. Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What are the common applications of PTFE balls? Leverage Unmatched Chemical Resistance & Low Friction