At its core, expanded Polytetrafluoroethylene (ePTFE) is suitable for aerospace because it combines exceptional resistance to extreme temperatures, aggressive chemicals, and high pressures with a unique, lightweight microporous structure. This allows it to perform reliably in critical components such as gaskets, seals, insulation, and protective vents, where failure is not an option.

The true value of ePTFE in aerospace is not just one superior property, but its rare ability to solve multiple, often conflicting, engineering challenges simultaneously. It provides robust sealing, chemical inertness, and thermal stability in a single, lightweight, and highly adaptable material.

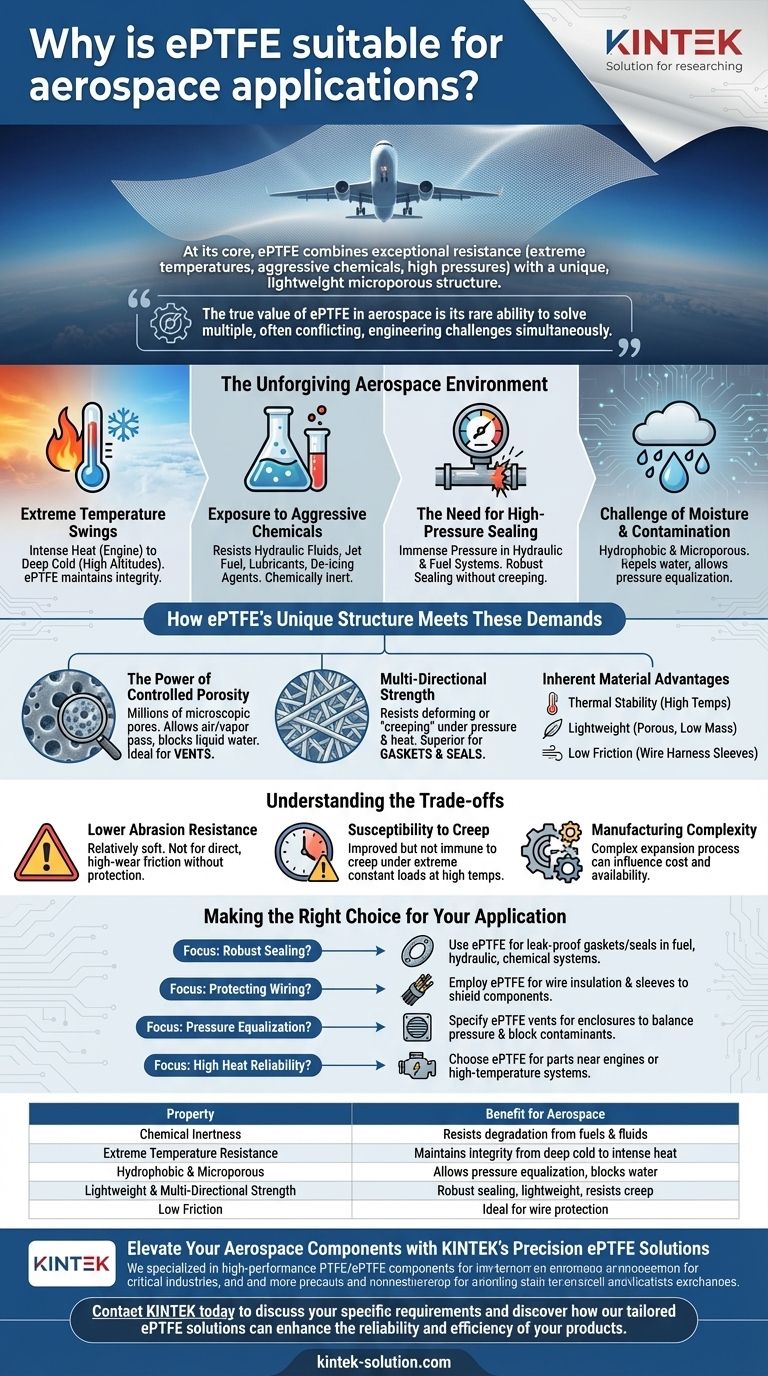

The Unforgiving Aerospace Environment

To understand why ePTFE is so critical, we must first appreciate the hostile conditions it must endure. Aerospace components operate in an environment of constant extremes.

Extreme Temperature Swings

Aircraft components are subjected to intense heat from engines and friction at high speeds, as well as deep cold at high altitudes. ePTFE maintains its integrity and flexibility across this vast thermal range, preventing material failure.

Exposure to Aggressive Chemicals

Aerospace systems rely on hydraulic fluids, jet fuel, lubricants, and de-icing agents. ePTFE is chemically inert, meaning it does not react with or degrade from contact with these harsh substances, ensuring the long-term reliability of seals and fluid passages.

The Need for High-Pressure Sealing

Hydraulic lines, fuel systems, and pressurized cabins operate under immense pressure. A seal failure can be catastrophic. The unique fibrous structure of ePTFE allows it to conform to surfaces and maintain a tight seal without creeping or deforming under sustained pressure.

The Challenge of Moisture and Contamination

From high-altitude condensation to ground-level rain, moisture is a constant threat that can cause corrosion or short-circuit electronics. ePTFE is hydrophobic, actively repelling water, and its controlled porosity is used in vents that allow pressure equalization while blocking water and other contaminants.

How ePTFE's Unique Structure Meets These Demands

ePTFE is not simply a solid plastic; it is a highly engineered material. Its manufacturing process creates a microporous, fibrous structure that gives it its remarkable versatility.

The Power of Controlled Porosity

ePTFE is filled with millions of microscopic pores. This structure is key to its multi-functionality. It can be engineered to allow air and vapor to pass through (for venting) while being small enough to block liquid water, thanks to its hydrophobic nature.

This property is essential for vents on sensitive electronic enclosures, which need to "breathe" to equalize pressure during altitude changes without letting in water or dust.

Multi-Directional Strength

Unlike standard PTFE, the "expanded" form has a fibrous, web-like structure. This gives it multi-directional strength, making it highly resistant to deforming or "creeping" under the combined forces of pressure and heat.

This is why ePTFE is a superior material for gaskets and seals. It maintains its shape and sealing force over time, even in demanding applications like the flange sealing of oxygen-carrying tubes.

Inherent Material Advantages

Beyond its structure, the base material offers fundamental benefits.

- Thermal Stability: It can operate continuously at high temperatures where other polymers would melt or degrade.

- Lightweight: Its porous nature makes it significantly lighter than alternative materials like metal or solid elastomers, a critical advantage in an industry where every gram counts.

- Low Friction: ePTFE has an extremely low coefficient of friction, making it an excellent material for wire harness sleeves and cable assemblies, allowing wires to be bundled and routed without chafing.

Understanding the Trade-offs

No material is perfect. Acknowledging ePTFE's limitations is key to using it effectively.

Lower Abrasion Resistance

ePTFE is a relatively soft material. While durable, it is not ideal for applications involving direct, high-wear friction or abrasion against rough surfaces without some form of protection.

Susceptibility to Creep

While its multi-directional structure vastly improves its resistance to creep (slow deformation under load) compared to standard PTFE, it is not immune. In applications with extremely high, constant loads at elevated temperatures, this must be a design consideration.

Manufacturing Complexity

The process of expanding PTFE to create its unique microporous structure is complex. This can influence its cost and availability compared to more common polymers or elastomers.

Making the Right Choice for Your Application

ePTFE's versatility means it can be tailored for specific goals.

- If your primary focus is robust sealing of fluids and gases: Use ePTFE for gaskets and seals in fuel, hydraulic, or chemical systems to ensure a leak-proof connection that resists pressure and chemical attack.

- If your primary focus is protecting wiring and electronics: Employ ePTFE for wire insulation and harness sleeves to shield components from heat, moisture, and chemical exposure in a lightweight package.

- If your primary focus is pressure equalization and venting: Specify ePTFE vents for enclosures to allow air to pass through for pressure balance while providing a durable barrier against water and contaminants.

- If your primary focus is component reliability under high heat: Choose ePTFE for parts near engines or high-temperature systems, such as sensor covers or insulation, where other materials would fail.

Ultimately, ePTFE is a cornerstone material in aerospace because it reliably solves multiple, complex engineering challenges with a single, versatile, and lightweight solution.

Summary Table:

| Property | Benefit for Aerospace |

|---|---|

| Chemical Inertness | Resists degradation from fuels, hydraulic fluids, and de-icing agents. |

| Extreme Temperature Resistance | Maintains integrity from deep cold at high altitudes to intense engine heat. |

| Hydrophobic & Microporous | Allows pressure equalization while blocking water and contaminants (ideal for vents). |

| Lightweight & Multi-Directional Strength | Provides robust sealing without adding significant weight; resists creep. |

| Low Friction | Ideal for wire harness sleeves to prevent chafing and protect critical wiring. |

Elevate Your Aerospace Components with KINTEK's Precision ePTFE Solutions

For semiconductor, medical, laboratory, and industrial clients, the reliability of your components is non-negotiable. KINTEK specializes in manufacturing high-performance PTFE and ePTFE components—including custom seals, liners, labware, and specialized parts—that meet the extreme demands of aerospace and other critical industries.

We combine precision production with expert custom fabrication, guiding your project from initial prototypes to high-volume production. Ensure your applications benefit from lightweight, chemically inert, and thermally stable materials engineered for peak performance.

Contact KINTEK today to discuss your specific requirements and discover how our tailored ePTFE solutions can enhance the reliability and efficiency of your products.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the biggest advantage of Teflon washers? Achieve Self-Lubricating, Low-Friction Performance

- How do PTFE oil scraper rings compare to metal oil scraper rings? Optimize Your Compressor's Performance

- What are the key properties of PTFE guide strips? Ensure Low-Friction, High-Temp Performance

- How do PTFE rotary shaft seals compare to traditional rubber seals? Superior Performance for Extreme Conditions

- How should PTFE sheets be maintained for optimal performance? Proactive Strategies for Longevity

- What are the flow characteristics of PTFE/PFA lined ball valves? Achieve Maximum Flow with Zero Contamination

- What makes PTFE envelope gaskets suitable for high-temperature applications? Superior Heat & Chemical Resistance

- How does the spring PTFE sealing ring achieve initial sealing contact? Master the Two-Stage Sealing Mechanism