In high-performance machinery, the key benefits of PTFE rotary shaft seals are their outstanding resistance to extreme temperatures and chemicals, their capability to handle high speeds and pressures, and their exceptionally low friction. These properties allow them to provide reliable sealing in demanding applications where conventional elastomeric seals would fail.

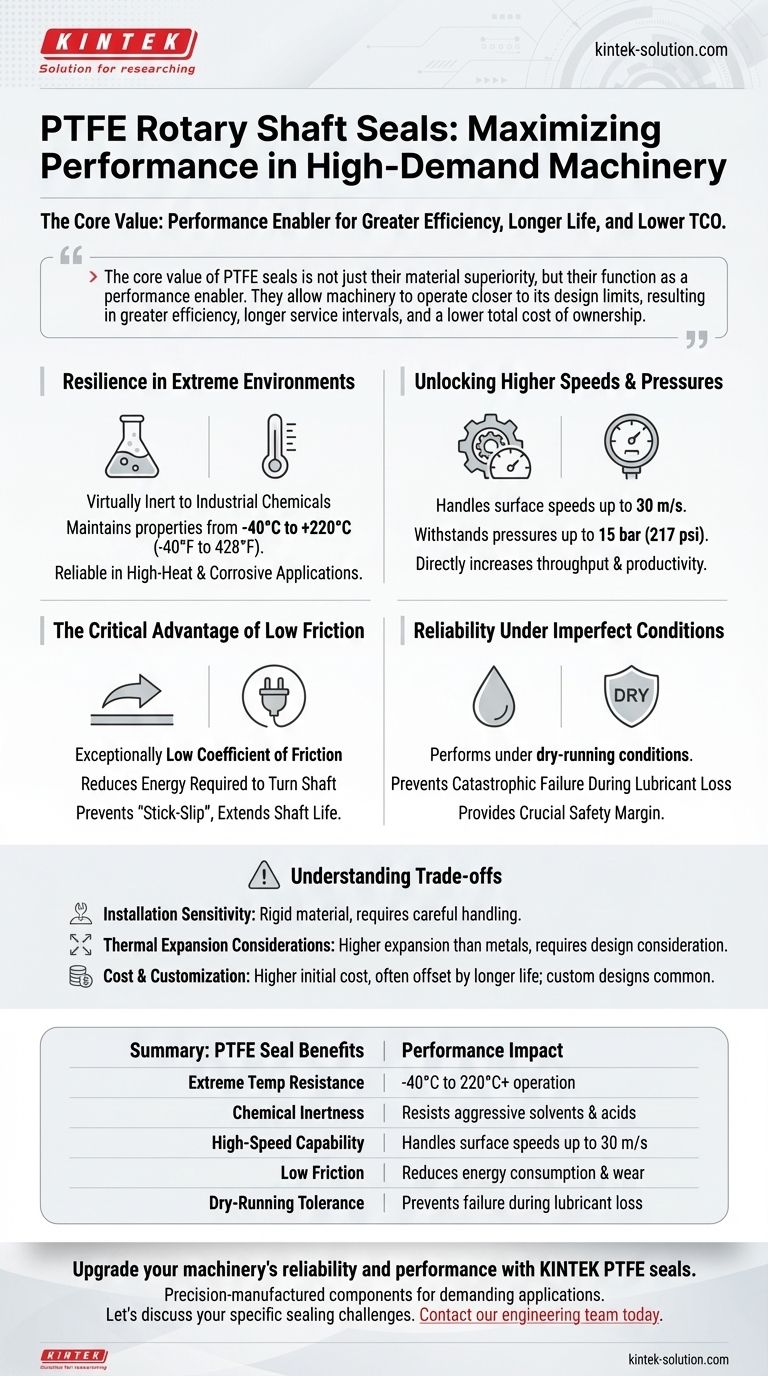

The core value of PTFE seals is not just their material superiority, but their function as a performance enabler. They allow machinery to operate closer to its design limits, resulting in greater efficiency, longer service intervals, and a lower total cost of ownership.

How PTFE Properties Drive Machine Performance

The unique characteristics of Polytetrafluoroethylene (PTFE) translate directly into tangible operational advantages for high-performance equipment. Understanding these links is key to justifying their use.

Resilience in Extreme Environments

PTFE is virtually inert to most industrial chemicals and solvents. This makes it an essential choice for applications in chemical processing, pharmaceuticals, and food production where seal integrity cannot be compromised.

Furthermore, these seals maintain their properties across a broad temperature range, typically from -40°C to over 220°C (-40°F to 428°F). This allows them to function reliably in high-heat applications like gearboxes and engines without hardening or degrading.

Unlocking Higher Speeds and Pressures

High-performance machinery often involves high rotational speeds and internal pressures. PTFE seals are engineered to handle surface speeds up to 30 m/s and pressures up to 15 bar (217 psi).

This capability allows equipment to be pushed harder and run faster, directly increasing throughput and productivity without the risk of premature seal failure.

The Critical Advantage of Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property significantly reduces the energy required to turn the shaft, directly boosting the machine's overall energy efficiency.

This low-friction nature also prevents "stick-slip" behavior during startup, ensuring smooth, predictable operation. More importantly, it dramatically reduces wear on the expensive machinery shaft, extending its operational life.

Reliability Under Imperfect Conditions

A standout feature of PTFE seals is their ability to perform under dry-running conditions. In moments of temporary lubricant starvation, a PTFE seal is far less likely to overheat and fail compared to a traditional rubber seal.

This characteristic provides a crucial margin of safety, preventing catastrophic failure and protecting the machinery from severe damage during unexpected operational issues.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. An objective assessment requires acknowledging their specific design and handling considerations.

Installation Sensitivity

PTFE is a more rigid material than common elastomers like nitrile rubber. This lack of elasticity means PTFE seals are more susceptible to damage during installation if proper tools and procedures are not used.

Care must be taken to avoid scratching or nicking the seal lip, as even minor damage can compromise sealing performance.

Thermal Expansion Considerations

PTFE has a higher coefficient of thermal expansion compared to metals. This means it expands and contracts more significantly with temperature changes.

Hardware and housing design must account for this expansion to ensure the seal maintains the correct contact pressure on the shaft across its full operating temperature range.

Cost and Customization

Virgin PTFE and specialized filled PTFE compounds can have a higher initial material cost than standard elastomers. However, this is often offset by longer life and reduced maintenance.

Because performance is highly dependent on design, many high-performance applications require custom-designed seals, which can involve engineering costs and longer lead times.

Making the Right Choice for Your Application

Selecting the right seal requires aligning its benefits with your primary operational goal.

- If your primary focus is maximizing uptime and reliability: PTFE's superior wear resistance and its tolerance for dry-running conditions provide a robust defense against premature failure and costly downtime.

- If your primary focus is operating in extreme temperatures or with aggressive chemicals: The inherent stability of PTFE makes it the definitive choice where traditional seals would rapidly degrade and fail.

- If your primary focus is boosting energy efficiency and performance: The exceptionally low friction of PTFE reduces parasitic drag and heat generation, allowing machinery to run faster and consume less energy.

Ultimately, choosing a PTFE rotary shaft seal is an investment in your machinery's long-term performance and operational resilience.

Summary Table:

| Key Benefit | Performance Impact |

|---|---|

| Extreme Temperature Resistance | -40°C to 220°C+ operation |

| Chemical Inertness | Resists aggressive solvents & acids |

| High-Speed Capability | Handles surface speeds up to 30 m/s |

| Low Friction | Reduces energy consumption & wear |

| Dry-Running Tolerance | Prevents failure during lubricant loss |

Upgrade your machinery's reliability and performance with KINTEK PTFE seals.

Our precision-manufactured PTFE components—including custom rotary shaft seals, liners, and labware—are engineered to withstand the most demanding conditions in semiconductor, medical, laboratory, and industrial applications. By prioritizing precision production and offering custom fabrication from prototypes to high-volume orders, we ensure your equipment achieves maximum uptime, energy efficiency, and a lower total cost of ownership.

Let's discuss how our PTFE solutions can solve your specific sealing challenges. Contact our engineering team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- When and by whom was PTFE discovered? A Tale of Accidental Innovation