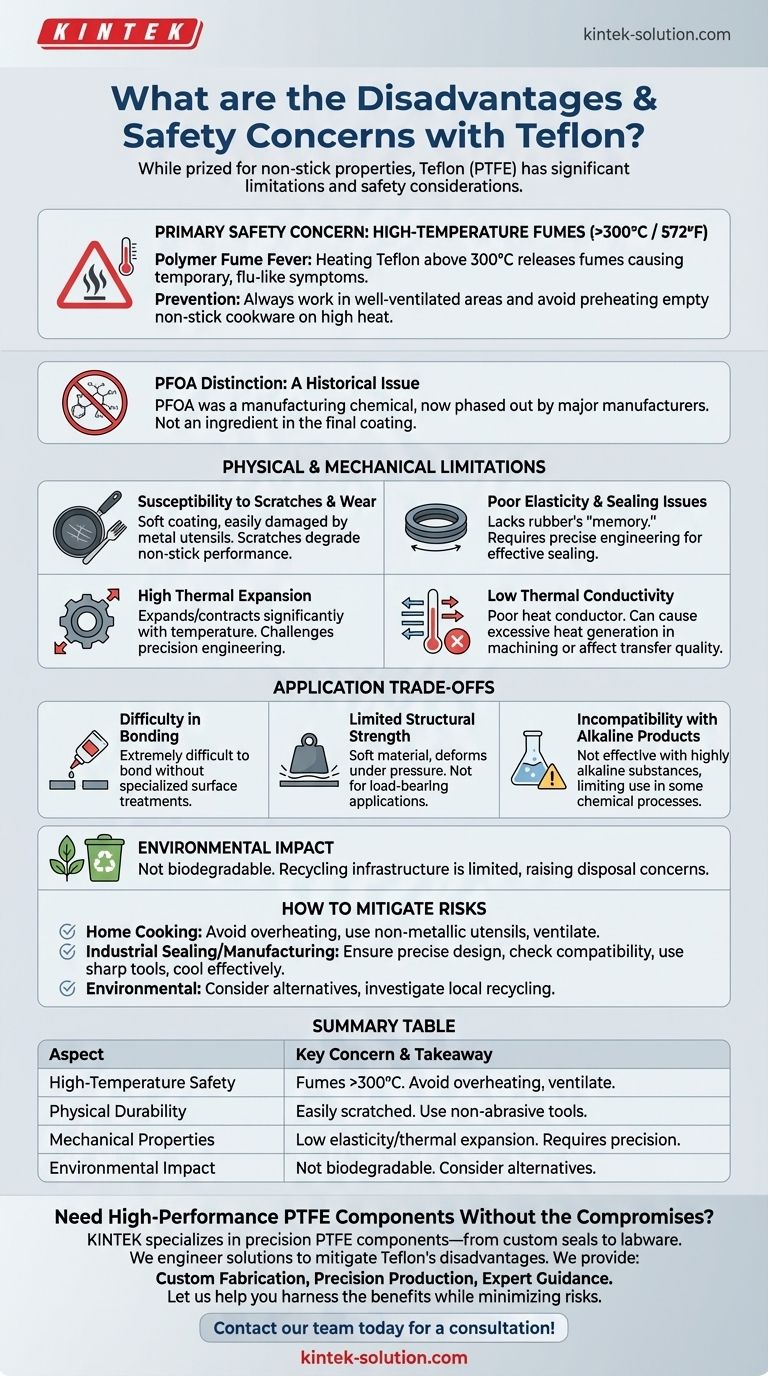

While prized for its exceptional non-stick properties, Teflon (PTFE) is not without significant disadvantages and safety concerns. The most widely cited safety issue is the release of potentially toxic fumes when it is heated above 300°C (572°F). Beyond this thermal instability, Teflon's limitations include poor durability against scratches, challenges in manufacturing and bonding, and environmental persistence.

The core issue with Teflon is not that it's inherently hazardous in normal use, but that its unique chemical and physical properties create specific limitations. Understanding its temperature sensitivity, physical fragility, and environmental impact is critical for using it safely and effectively.

The Primary Safety Concern: High-Temperature Fumes

The most immediate safety risk associated with Teflon coatings is related to extreme heat, a condition rarely encountered in its intended applications like home cooking.

Understanding "Polymer Fume Fever"

When heated to temperatures exceeding 300°C (572°F), PTFE begins to break down. This degradation process releases fumes that can cause temporary, flu-like symptoms in humans, a condition known as polymer fume fever.

To prevent this, you should always work in a well-ventilated area and avoid preheating empty non-stick cookware on high heat, as an empty pan can reach these temperatures very quickly.

The PFOA Distinction: A Historical Issue

Much of the long-term health concern surrounding Teflon has been linked to Perfluorooctanoic acid (PFOA). It's crucial to understand that PFOA was a chemical used in the manufacturing process of Teflon, not an ingredient in the final non-stick coating itself.

Due to its environmental persistence and potential health risks, PFOA has been phased out of production by major global manufacturers, so it is not a concern with newly produced Teflon products.

Physical and Mechanical Limitations

Beyond safety, Teflon's material properties present several practical disadvantages in both consumer and industrial settings.

Susceptibility to Scratches and Wear

Teflon coatings are inherently soft and can be easily damaged by metal utensils or abrasive cleaning pads. Once a coating is scratched, its non-stick performance degrades rapidly.

Over time, damaged coatings can begin to peel or flake, which, while not considered toxic, compromises the product's function.

Poor Elasticity and Sealing Issues

In its solid form, such as in O-rings or seals, Teflon lacks the elasticity or "memory" of rubber. This rigidity can lead to sealing challenges in dynamic applications that require significant compression and recovery.

Effective sealing with solid PTFE often requires very precise engineering and groove design to compensate for this lack of flexibility.

High Thermal Expansion

Teflon expands and contracts with temperature changes significantly more than most other plastics or metals. This high coefficient of thermal expansion can be a major challenge in precision engineering applications where tight tolerances are critical.

Low Thermal Conductivity

As a poor conductor of heat, Teflon can cause issues with heat management. During machining, this can lead to excessive heat generation. In applications like heat-press printing, a Teflon sheet may absorb some heat, potentially affecting the quality of the transfer.

Understanding the Trade-offs in Application

Teflon's defining characteristic—its slipperiness—is both its greatest strength and a source of significant limitations.

Difficulty in Bonding

The same non-stick quality that makes Teflon ideal for cookware also makes it extremely difficult to bond to other materials using conventional adhesives. Specialized surface treatments are required to make it adhere properly.

Limited Structural Strength

Teflon is a soft material and is not suitable for load-bearing or structural applications. It deforms easily under pressure, limiting its use to coatings, liners, and low-stress components.

Incompatibility with Alkaline Products

While famous for its chemical resistance, Teflon packing and seals are not effective when used with highly alkaline substances. This limits their suitability in certain industrial chemical processes.

Environmental Persistence

Teflon is a type of plastic that is not biodegradable, raising legitimate environmental concerns about its disposal. While PTFE is technically recyclable, the infrastructure for this process is not widely available.

How to Mitigate Teflon's Risks

Choosing and using Teflon-coated or solid PTFE products safely comes down to understanding the context of your specific application.

- If your primary focus is home cooking: Avoid overheating empty pans, use non-metallic utensils, and ensure your kitchen is well-ventilated to eliminate nearly all risks.

- If your primary focus is industrial sealing: Ensure precise groove design to compensate for low elasticity and verify chemical compatibility, especially with alkaline substances.

- If your primary focus is manufacturing or machining: Use sharp carbide tools, low cutting speeds, and effective cooling to manage heat generation and prevent material deformation.

- If your primary focus is environmental impact: Consider alternative materials where possible and investigate local recycling options for end-of-life PTFE products.

By respecting its specific limitations, you can leverage Teflon's unique benefits while minimizing its inherent disadvantages.

Summary Table:

| Aspect | Key Concern | Key Takeaway |

|---|---|---|

| High-Temperature Safety | Releases toxic fumes above 300°C (572°F). | Avoid overheating; ensure proper ventilation. |

| Physical Durability | Soft coating, easily scratched by metal utensils. | Use non-abrasive tools; handle with care. |

| Mechanical Properties | Low elasticity, high thermal expansion, difficult to bond. | Requires precise engineering for sealing applications. |

| Environmental Impact | Not biodegradable; recycling infrastructure is limited. | Consider material alternatives for sustainability. |

Need High-Performance PTFE Components Without the Compromises?

At KINTEK, we specialize in manufacturing precision PTFE components—from custom seals and liners to specialized labware—for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical balance between leveraging Teflon's unique properties and mitigating its disadvantages through expert design and material science.

We provide:

- Custom Fabrication: Tailored solutions from prototypes to high-volume orders to meet your exact specifications and application challenges.

- Precision Production: Meticulous engineering to overcome PTFE's limitations, such as compensating for low elasticity and thermal expansion.

- Expert Guidance: Assistance in selecting the right material and design for your needs, ensuring safety, durability, and performance.

Let us help you harness the benefits of PTFE while minimizing the risks. Contact our team today for a consultation on your next project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What medical applications benefit from PTFE? A Guide to Its Critical Role in Healthcare

- How is Teflon (PTFE) produced chemically? Unlocking the Secrets of High-Performance Polymer Manufacturing

- How do molybdenum disulfide fillers improve PTFE? Enhance Wear Resistance and Lubricity

- How does PTFE compare to other materials in terms of chemical resistance? The Unmatched Leader in Chemical Inertness

- What are some physical properties of PTFE? Master Its Unique Properties for Extreme Applications

- What are the dielectric properties of PTFE products? Ensure Stable, High-Performance Electrical Insulation

- What are the limitations of PTFE in its applications? Understanding Its Mechanical Weaknesses

- How does RPTFE differ from PTFE in terms of reactivity? A Guide to Chemical Compatibility