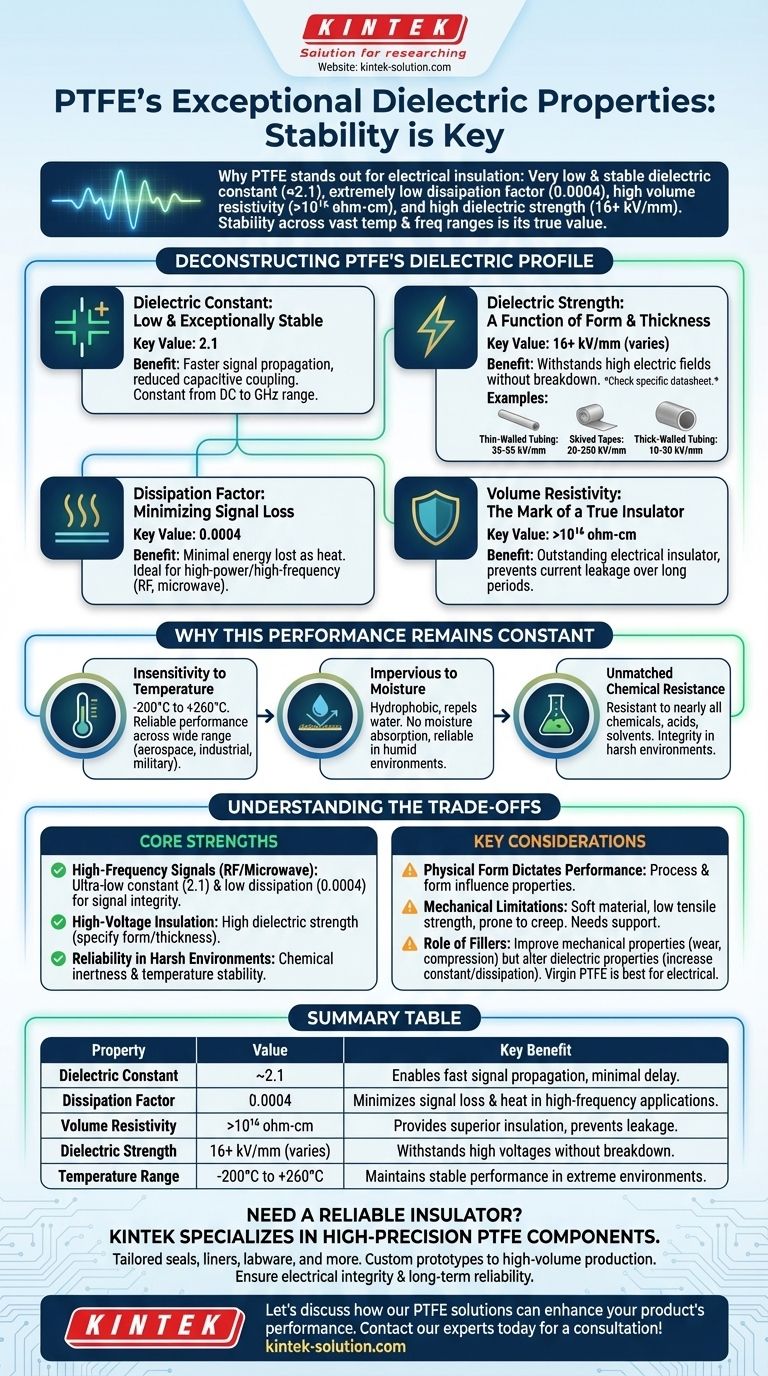

When selecting a material for electrical insulation, PTFE (polytetrafluoroethylene) stands out due to its combination of exceptional dielectric properties. It maintains a very low and stable dielectric constant of approximately 2.1, an extremely low dissipation factor of 0.0004, high volume resistivity exceeding 10¹⁶ ohm-cm, and a high dielectric strength that typically starts above 16 kV/mm.

The true value of PTFE is not just its individual electrical metrics, but the remarkable stability of these properties across a vast range of temperatures and frequencies. This consistency makes it a uniquely reliable insulator for the most demanding applications.

Deconstructing PTFE's Dielectric Profile

To properly evaluate PTFE, we must look at each core dielectric property and understand its practical implication. These metrics collectively define its performance as an electrical insulator.

The Dielectric Constant: Low and Exceptionally Stable

The dielectric constant measures a material's ability to store electrical energy in an electric field. PTFE’s low value of 2.1 is a significant advantage.

A lower dielectric constant allows for faster signal propagation and reduces capacitive coupling between conductors, which is critical for high-frequency circuits. Most importantly, this value remains nearly constant from DC up into the gigahertz (GHz) range.

Dielectric Strength: A Function of Form and Thickness

Dielectric strength indicates the maximum electric field a material can withstand without breaking down and conducting electricity. While often cited as a single value, for PTFE, it is highly dependent on the product's form and thickness.

For example, ASTM standards specify different ranges for different forms:

- Thin-Walled Tubing (ASTM D3295): 35-55 kV/mm

- Skived Tapes (ASTM D3308): 20-250 kV/mm

- Thick-Walled Tubing (ASTM D1710): 10-30 kV/mm

This variation underscores the need to consult the specific datasheet for the product you intend to use.

Dissipation Factor: Minimizing Signal Loss

The dissipation factor, or loss tangent, represents the energy that is lost and converted to heat within the material. PTFE’s extremely low dissipation factor of 0.0004 is one of its most prized characteristics.

This means very little signal energy is wasted as heat, making PTFE an ideal choice for high-power or high-frequency applications like RF connectors, microwave circuits, and coaxial cable insulation.

Volume Resistivity: The Mark of a True Insulator

Volume resistivity measures a material's resistance to leakage current flowing through its bulk. With a value greater than 10¹⁶ ohm-cm, PTFE is an outstanding electrical insulator.

This property ensures that it effectively isolates conductors and prevents current loss over long periods, even under high voltage stress.

Why This Performance Remains Constant

An insulator's properties are only as good as their stability. PTFE's primary advantage is its ability to maintain its excellent dielectric profile in conditions where other materials would degrade.

Insensitivity to Temperature

PTFE operates reliably across an exceptionally wide temperature range, from cryogenic conditions at -200°C up to 260°C. Its dielectric properties show no significant alteration within this range, ensuring predictable performance in aerospace, industrial, and military systems.

Impervious to Moisture

PTFE is hydrophobic, meaning it repels water. It does not absorb moisture from the air, a common cause of electrical property degradation in many other polymers. This makes its performance highly reliable in humid or outdoor environments.

Unmatched Chemical Resistance

As one of the most inert known polymers, PTFE is resistant to nearly all chemicals, acids, and solvents. This ensures that its physical integrity and electrical insulating properties are not compromised by exposure to harsh industrial or chemical environments.

Understanding the Trade-offs

No material is perfect. While its electrical and chemical properties are superb, PTFE has clear mechanical limitations that must be considered during design.

Physical Form Dictates Performance

As noted with dielectric strength, you cannot design using a single generic value. The manufacturing process and final form—whether it's a thin skived tape, a molded sheet, or an extruded tube—directly influence the final electrical and mechanical properties.

Mechanical Limitations

PTFE is a relatively soft material with low tensile strength and a tendency to deform under sustained load, a phenomenon known as "creep." It is not a structural material and requires mechanical support in most applications to prevent deformation.

The Role of Fillers

To improve its mechanical properties like wear resistance and compressive strength, PTFE is often mixed with fillers like glass, carbon, or bronze. However, these additives will almost always alter the dielectric properties, typically increasing the dielectric constant and dissipation factor. Pure, or "virgin," PTFE offers the best electrical performance.

Making the Right Choice for Your Application

Your specific goal will determine which of PTFE's properties is most valuable.

- If your primary focus is high-frequency signals (RF/Microwave): The ultra-low and stable dielectric constant (2.1) and low dissipation factor (0.0004) are your most critical advantages, ensuring signal integrity.

- If your primary focus is high-voltage insulation: The high dielectric strength is key, but you must specify the material form (tape, sheet) and thickness to ensure it meets your voltage standoff requirements.

- If your primary focus is reliability in harsh environments: Its chemical inertness and performance stability across a wide temperature range ensure consistent electrical properties where other insulators would fail.

By understanding these distinct properties and their practical trade-offs, you can confidently specify PTFE where stable, high-performance electrical insulation is non-negotiable.

Summary Table:

| Property | Value | Key Benefit |

|---|---|---|

| Dielectric Constant | ~2.1 | Enables fast signal propagation, minimal signal delay. |

| Dissipation Factor | 0.0004 | Minimizes signal loss and heat generation in high-frequency applications. |

| Volume Resistivity | >10¹⁶ ohm-cm | Provides superior insulation, preventing current leakage. |

| Dielectric Strength | 16+ kV/mm (varies by form) | Withstands high voltages without breakdown. |

| Temperature Range | -200°C to +260°C | Maintains stable performance in extreme environments. |

Need a Reliable Insulator for Your Critical Application?

PTFE's exceptional dielectric properties—low constant, high strength, and unmatched stability—make it the ideal choice for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

KINTEK specializes in manufacturing high-precision PTFE components (seals, liners, labware, and more) tailored to your exact specifications. Whether you require custom prototypes or high-volume production, we deliver components that ensure electrical integrity and long-term reliability.

Let's discuss how our PTFE solutions can enhance your product's performance. Contact our experts today for a consultation!

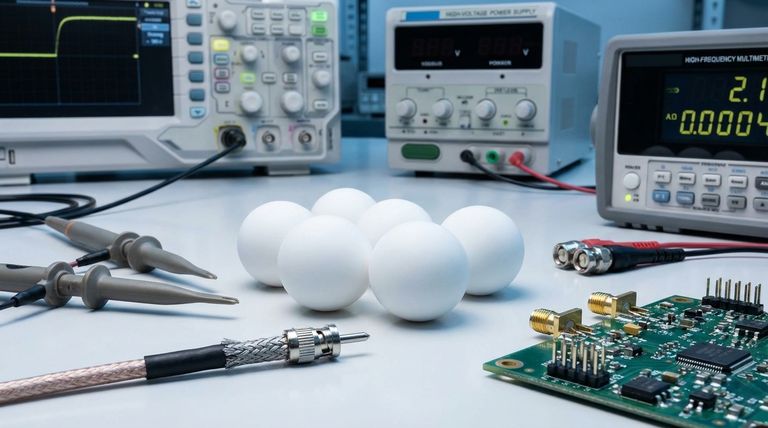

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments