In the medical field, Polytetrafluoroethylene (PTFE) is a critical material used for life-saving implants like vascular grafts, minimally invasive devices such as catheters, and essential components in surgical instruments and laboratory equipment. Its value stems from a unique combination of properties: it is highly biocompatible, chemically non-reactive, and has an extremely low-friction surface.

The widespread use of PTFE in medicine is not due to a single trait, but its rare combination of being safe for the human body (biocompatible), unreactive to bodily fluids and harsh sterilizers (inert), and exceptionally slippery (low friction).

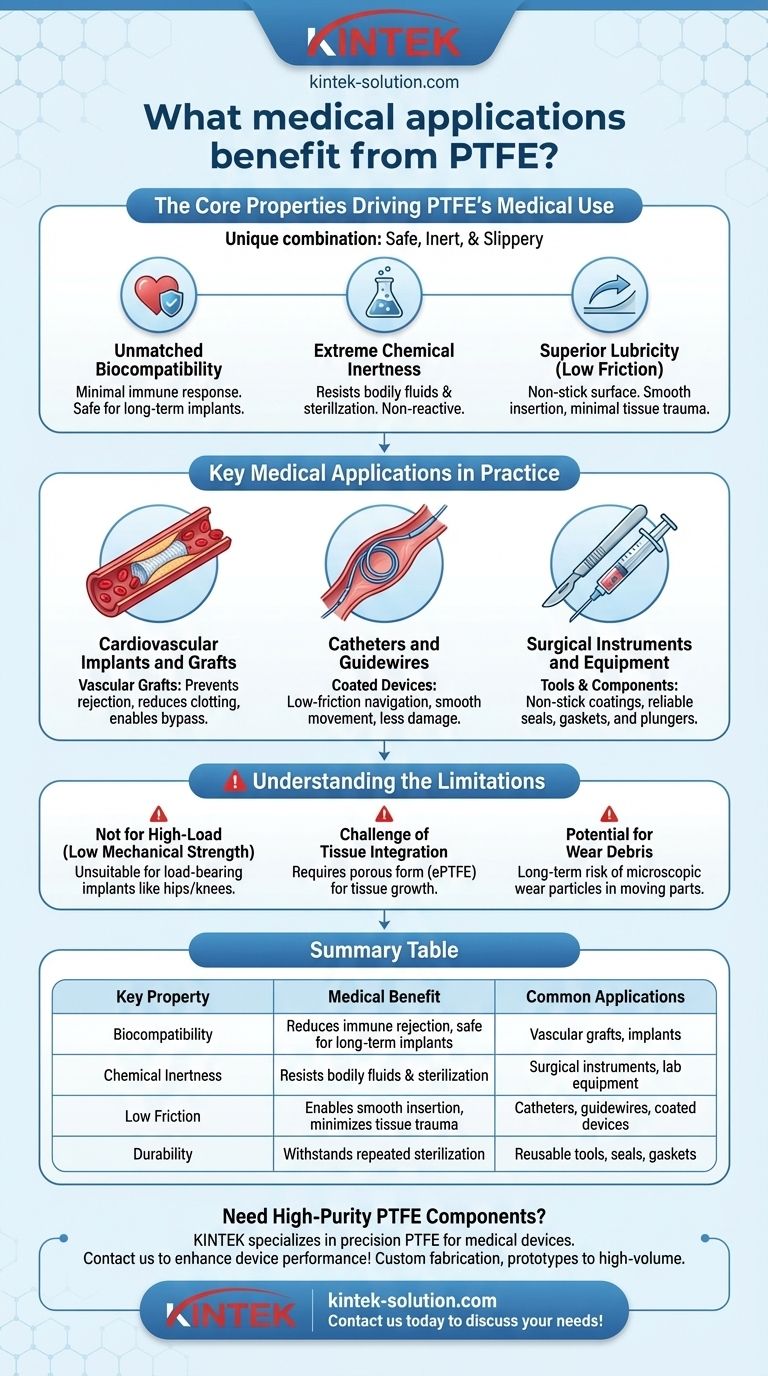

The Core Properties Driving PTFE's Medical Use

To understand why PTFE is so prevalent in sensitive medical applications, we must first look at its fundamental characteristics. These properties work in concert to ensure both patient safety and device performance.

Unmatched Biocompatibility

PTFE is one of the most biocompatible polymers known. This means the human body’s immune system does not typically recognize it as a foreign invader, drastically reducing the risk of rejection or inflammation. This makes it a premier choice for long-term implants that reside within the body for years.

Extreme Chemical Inertness

This material is almost completely inert, meaning it does not react with chemicals. In a medical context, this is crucial. It ensures that a PTFE implant will not break down when exposed to bodily fluids, nor will it leach harmful substances into the patient's system. This property also allows it to withstand aggressive sterilization methods like autoclaving.

Superior Lubricity (Low Friction)

PTFE has one of the lowest coefficients of friction of any solid material, giving it a uniquely "non-stick" or slippery surface. This is vital for devices that must move through delicate tissues, such as blood vessels. A PTFE coating allows a catheter to glide smoothly, minimizing trauma during insertion and navigation.

Durability and Sterilization

Medical devices must be sterile to prevent infection. PTFE can be reliably sterilized using common medical methods without degrading its physical properties, ensuring it can be used safely in hygienic environments.

Key Medical Applications in Practice

These core properties translate directly into specific, high-stakes medical uses where performance and safety are non-negotiable.

Cardiovascular Implants and Grafts

PTFE is famously used to create vascular grafts, which are artificial blood vessels used to bypass or replace blocked arteries. The material's biocompatibility prevents rejection, and its smooth internal surface helps reduce the risk of blood clots forming.

Catheters and Guidewires

Thin coatings of PTFE are applied to catheters and medical guidewires. This low-friction surface is essential for enabling physicians to navigate these devices through the intricate and fragile network of a patient’s vascular system with minimal damage.

Surgical Instruments and Equipment

PTFE's non-stick properties are valuable for coating surgical tools. In a different capacity, it is used to make components like seals, gaskets, and syringe plungers, where its chemical resistance and smooth, frictionless movement are critical for reliable and hygienic operation.

Understanding the Limitations

While highly versatile, PTFE is not a universal solution. Acknowledging its trade-offs is key to its proper application.

Not a Solution for High-Load Applications

PTFE is a relatively soft polymer. It lacks the mechanical strength required for load-bearing orthopedic implants like artificial hips or knee joints, which are typically made from titanium alloys and specialized ceramics.

The Challenge of Tissue Integration

Because PTFE is so inert, living tissue does not naturally bond to it. For applications like vascular grafts, the material is often processed into an expanded, porous form (ePTFE) to create a microscopic scaffold that encourages the patient's own cells to grow into it, anchoring the implant securely.

Potential for Wear Debris

In any application involving moving parts, there is a long-term risk of microscopic wear particles being generated. While solid PTFE is biocompatible, the body's response to an accumulation of fine particles over many decades remains a consideration for material scientists.

Making the Right Choice for Your Application

Selecting the right material in medical device design is a critical decision based on the device's primary function.

- If your primary focus is permanent implantation: Biocompatibility and chemical inertness are the most critical factors, making PTFE an elite choice for devices like grafts.

- If your primary focus is smooth insertion and navigation: The unmatched low-friction surface of PTFE is the defining feature for coating catheters and guidewires.

- If your primary focus is reusable instruments or lab equipment: Chemical resistance for sterilization and non-reactivity to preserve sample purity are the key advantages.

Ultimately, PTFE's unique combination of safety, stability, and performance makes it an indispensable material in modern medicine.

Summary Table:

| Key Property | Medical Benefit | Common Applications |

|---|---|---|

| Biocompatibility | Reduces immune rejection, safe for long-term implants | Vascular grafts, implants |

| Chemical Inertness | Resists bodily fluids & sterilization | Surgical instruments, lab equipment |

| Low Friction | Enables smooth insertion, minimizes tissue trauma | Catheters, guidewires, coated devices |

| Durability | Withstands repeated sterilization | Reusable tools, seals, gaskets |

Need High-Purity PTFE Components for Your Medical Devices?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the medical, semiconductor, and laboratory industries. Our expertise ensures biocompatibility, chemical resistance, and reliability for critical applications like catheters, surgical tools, and diagnostic equipment.

We offer custom fabrication from prototypes to high-volume orders, prioritizing quality and precision to meet stringent medical standards.

Contact us today to discuss your PTFE component needs and enhance your medical device performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F