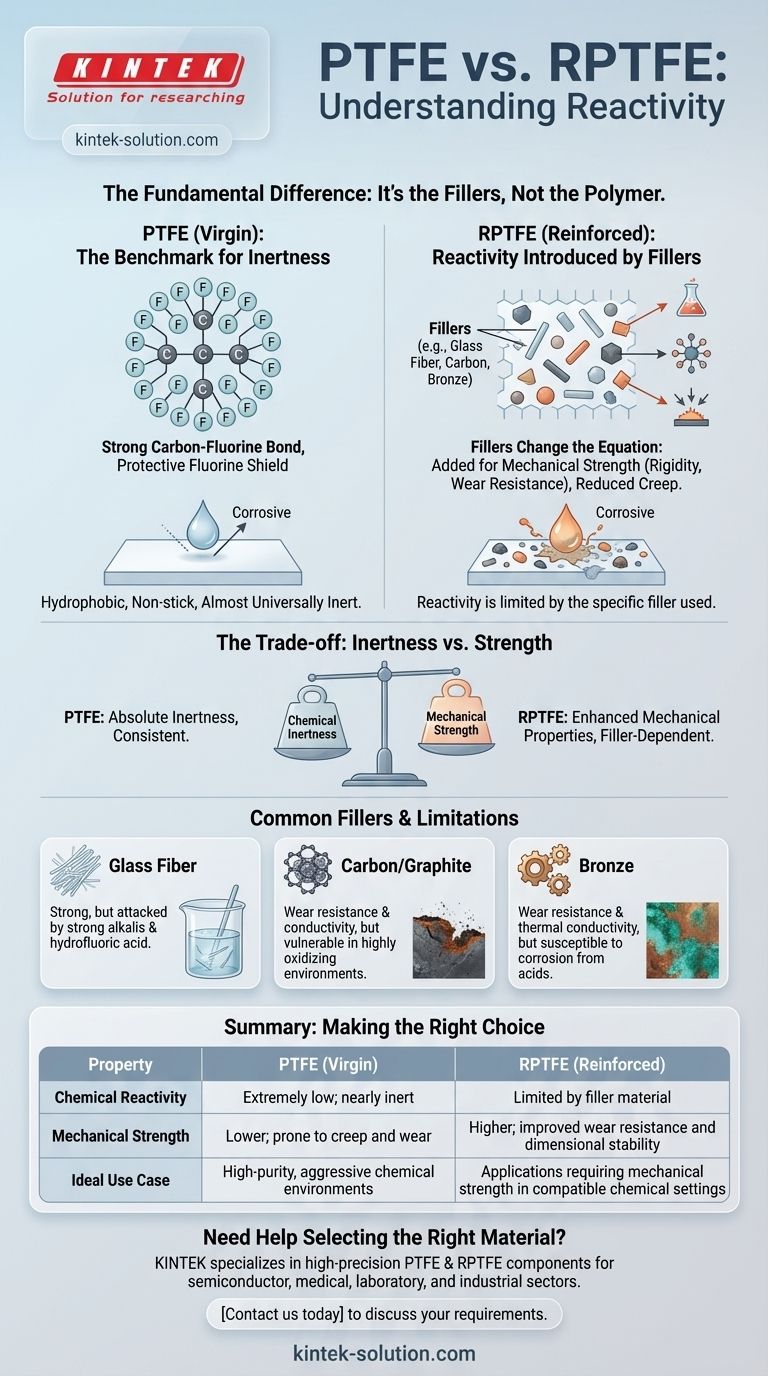

The fundamental difference in reactivity lies not in the base polymer, but in what is added to it. While pure Polytetrafluoroethylene (PTFE) is one of the most chemically inert substances known, Reinforced PTFE (RPTFE) introduces filler materials that can react with their environment, altering its chemical compatibility.

The choice between PTFE and RPTFE is a direct trade-off between absolute chemical inertness and enhanced mechanical properties. The reactivity of RPTFE is not a property of the plastic itself, but a direct consequence of the specific reinforcing filler used.

The Foundation: Why PTFE Is So Non-Reactive

To understand the difference, we must first establish why pure PTFE is a benchmark for chemical resistance. Its properties are rooted in its molecular structure.

The Carbon-Fluorine Bond

At its core, PTFE is a simple polymer made of long chains of carbon atoms, where each carbon is bonded to two fluorine atoms. The bond between carbon and fluorine is exceptionally strong—one of the strongest known single bonds in organic chemistry.

A Protective Fluorine Shield

These fluorine atoms are larger than the carbon atoms they are bonded to. They form a tight, dense, and uniform helical sheath around the carbon backbone, effectively shielding it from chemical attack. This stable, non-polar structure is what makes PTFE hydrophobic, non-stick, and almost universally inert.

Introducing Reactivity: The Role of Fillers in RPTFE

If PTFE is so stable, the need for RPTFE arises from its mechanical weaknesses. The reinforcement process, however, fundamentally changes its chemical profile.

Why Reinforce PTFE?

Despite its chemical stability, pure PTFE is a relatively soft material. It is highly susceptible to deformation under load, a phenomenon known as "creep." It also has a high rate of wear in dynamic applications.

How Fillers Change the Equation

To counteract these weaknesses, reinforcing agents or fillers are blended into the PTFE matrix. Common fillers include glass fiber, carbon, graphite, or bronze. These materials add rigidity, improve wear resistance, and reduce deformation.

The Source of New Reactivity

The crucial point is that these fillers are not as inert as PTFE. While the PTFE matrix remains non-reactive, the exposed filler material can and will react with certain chemicals. This means the chemical resistance of an RPTFE component is limited by the resistance of its specific filler.

Understanding the Trade-offs

Selecting the correct material requires a clear understanding of what you are gaining and what you are sacrificing.

Chemical Inertness vs. Mechanical Strength

This is the central trade-off. Virgin PTFE should be the choice for applications demanding the highest degree of chemical resistance, especially with aggressive or high-purity media. RPTFE is for applications where mechanical strength, wear resistance, and dimensional stability are critical, and the chemical environment is known to be compatible with the filler.

Common Fillers and Their Limitations

The reactivity of RPTFE depends entirely on its contents.

- Glass Fiber: A common filler for general strength, but it can be attacked by strong alkalis (like sodium hydroxide) and hydrofluoric acid.

- Carbon/Graphite: Improves wear resistance and conductivity. However, it can be vulnerable in highly oxidizing environments.

- Bronze: Provides excellent wear resistance and thermal conductivity but is susceptible to corrosion from acids and other media that attack copper alloys.

The Purity Consideration

For industries like semiconductor manufacturing, biotechnology, or high-purity pharmaceuticals, fillers can be a source of contamination. In these cases, the potential for fillers to leach into the process fluid makes virgin PTFE the only acceptable choice.

Making the Right Choice for Your Application

Your final decision must be guided by the primary demands of your specific engineering challenge.

- If your primary focus is absolute chemical inertness: Always choose pure, virgin PTFE, as its properties are consistent and predictable across the widest range of chemicals.

- If your primary focus is mechanical performance under load: Select RPTFE, but you must first verify that the specific filler material is fully compatible with your chemical environment.

- If your primary focus is preventing contamination: Virgin PTFE is the correct choice to eliminate any risk of leaching from reinforcing agents.

By understanding this distinction, you can select a material based on a calculated engineering trade-off rather than just its name.

Summary Table:

| Property | PTFE (Virgin) | RPTFE (Reinforced) |

|---|---|---|

| Chemical Reactivity | Extremely low; nearly inert | Limited by filler material (e.g., glass, carbon, bronze) |

| Mechanical Strength | Lower; prone to creep and wear | Higher; improved wear resistance and dimensional stability |

| Ideal Use Case | High-purity, aggressive chemical environments | Applications requiring mechanical strength in compatible chemical settings |

Need help selecting the right PTFE material for your application? At KINTEK, we specialize in manufacturing high-precision PTFE and RPTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the absolute chemical inertness of virgin PTFE or the enhanced mechanical properties of reinforced PTFE, our team can provide tailored solutions from prototypes to high-volume orders. Contact us today to discuss your specific requirements and ensure optimal performance in your environment!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the benefits of stainless steel-filled PTFE? Enhance Strength and Temperature Resistance

- What should be considered before specifying PTFE material for an application? Avoid Costly Design Failures

- What makes PTFE resistant to UV and weathering? The Science Behind its Inherent, Lasting Durability

- What is the chemical formula and CAS number for PTFE? Unlocking Its Unique Properties

- What is the best type of bearings for off-road use? The Definitive Guide to Rubber Sealed (2RS) Bearings

- In which industries is Teflon commonly used? Essential for Chemical, Medical, and Aerospace

- What materials are needed to synthesize PTFE? A Guide to the Core Ingredients and Process

- Is PTFE coating safe to use? A Guide to Safe Temperatures and Applications