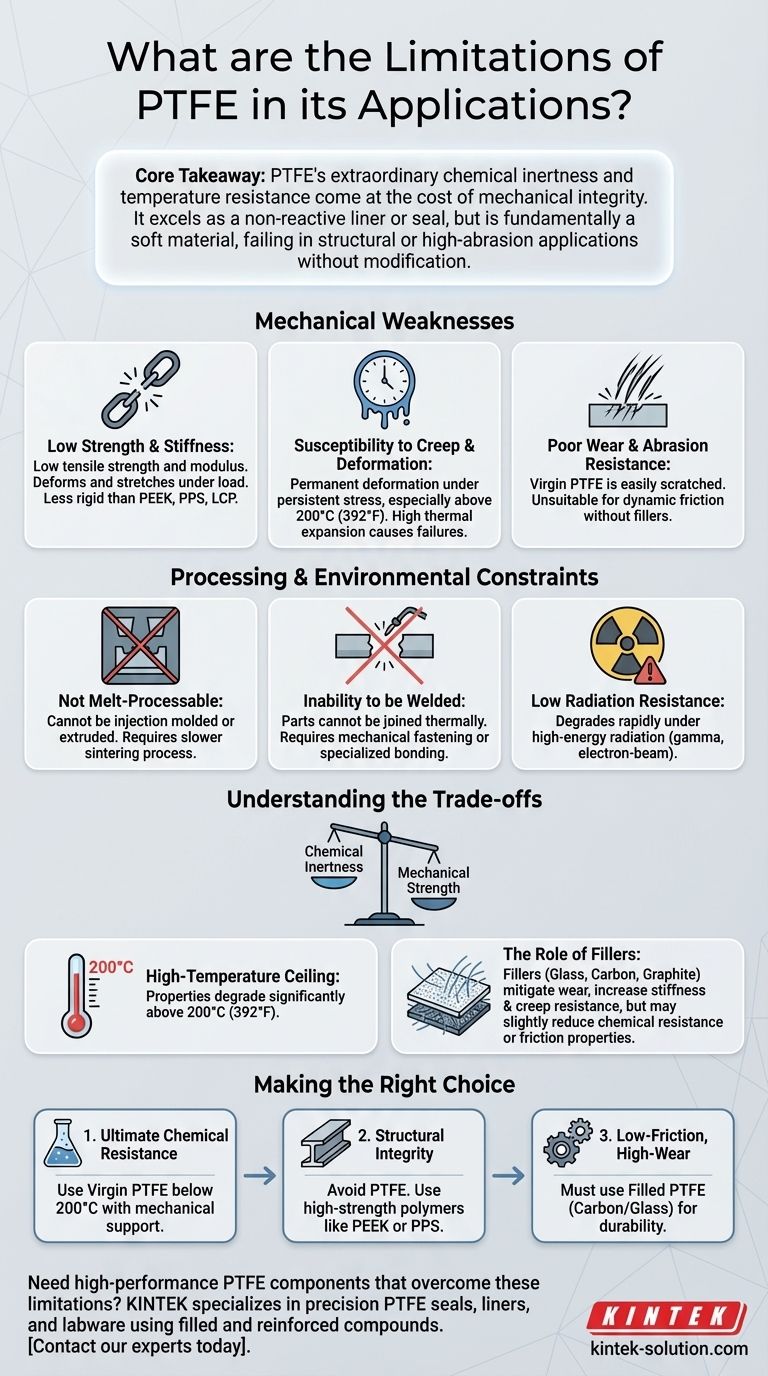

While Polytetrafluoroethylene (PTFE) is renowned for its exceptional properties, it is not a universally applicable material. Its primary limitations stem from significant mechanical weaknesses, including low tensile strength, poor wear and abrasion resistance in its pure form, a high susceptibility to creep (deformation under load), and an inability to be processed using conventional melt techniques like injection molding.

The central takeaway is that PTFE's extraordinary chemical inertness and temperature resistance come at the cost of mechanical integrity. While it excels as a non-reactive liner or seal, it is fundamentally a soft material that fails in applications requiring structural strength or high abrasion resistance without modification.

The Core Challenge: Understanding PTFE's Mechanical Weaknesses

The most common failures involving PTFE occur when its mechanical properties are overestimated. Engineers must design around these inherent soft material characteristics.

Low Strength and Stiffness

PTFE exhibits low tensile strength and modulus (stiffness) compared to other high-performance polymers. Materials like PEEK, PPS, and LCP are vastly superior in load-bearing applications.

This means that under physical stress, a PTFE component is much more likely to stretch, deform, or break than parts made from more rigid polymers.

Susceptibility to Creep and Deformation

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. PTFE is highly sensitive to this phenomenon, especially at elevated temperatures.

For example, at temperatures above 200°C (392°F), PTFE's thermal expansion is ten times that of stainless steel. This can lead to permanent deformation in components like valve seats, causing leaks or mechanism failure.

Poor Wear and Abrasion Resistance

In its unfilled (or virgin) state, PTFE has very high wear behavior. Its slick, non-stick surface can be easily scratched or worn away by abrasive contact, quickly compromising the component's integrity.

This makes virgin PTFE unsuitable for dynamic applications involving friction against hard or rough surfaces.

Processing and Environmental Constraints

Beyond its mechanical properties, PTFE presents unique challenges in manufacturing and specific operational environments.

Not a Melt-Processable Polymer

Unlike common thermoplastics, PTFE cannot be processed using conventional melt techniques such as injection molding or extrusion. It must be formed using a sintering process similar to powdered metallurgy, which can be slower and more costly.

This limitation restricts the complexity of shapes that can be easily manufactured and can impact high-volume production efficiency.

Inability to be Welded

PTFE parts cannot be joined together using thermal welding techniques. This complicates the fabrication of large or complex structures, often requiring mechanical fastening or bonding with specialized adhesives.

Low Radiation Resistance

PTFE has poor resistance to high-energy radiation, such as gamma or electron-beam radiation. Exposure causes the polymer chains to break down, leading to rapid degradation and a loss of all useful mechanical properties.

Understanding the Trade-offs

Selecting PTFE requires a clear understanding of what you are gaining versus what you are giving up.

The Chemical Inertness vs. Mechanical Strength Dilemma

The core trade-off is choosing PTFE's nearly universal chemical resistance over the structural robustness of other polymers. It can withstand the most aggressive chemicals but cannot support significant mechanical loads on its own.

The High-Temperature Ceiling

While PTFE is considered a high-temperature material, its useful resistance has a firm ceiling. Its properties degrade significantly above 200°C (392°F), and it can break down completely if exposed to prolonged high heat, making it a risk in applications like large, hot-area gaskets.

The Crucial Role of Fillers

Many of PTFE's mechanical limitations, particularly poor wear resistance, can be mitigated by adding fillers. Reinforcing PTFE with materials like glass fibers, carbon, or graphite dramatically increases its wear resistance, stiffness, and resistance to creep.

However, be aware that adding fillers can sometimes slightly reduce other desirable properties, such as its chemical resistance or coefficient of friction.

Making the Right Choice for Your Application

To apply PTFE successfully, align your primary goal with the material's strengths and weaknesses.

- If your primary focus is ultimate chemical resistance: Virgin PTFE is an excellent choice for liners, seals, and gaskets in static applications, provided you design to support it mechanically and operate below 200°C.

- If your primary focus is structural integrity or load-bearing: PTFE is almost certainly the wrong material. You should evaluate high-strength polymers like PEEK or PPS instead.

- If your primary focus is a low-friction, high-wear application: You must use a filled grade of PTFE. A carbon or glass-filled compound will provide the necessary durability that virgin PTFE lacks.

By respecting its inherent limitations, you can effectively leverage PTFE's remarkable properties for the right challenge.

Summary Table:

| Limitation | Impact on Application |

|---|---|

| Low Tensile Strength & Stiffness | Poor performance in load-bearing applications |

| High Susceptibility to Creep | Deformation under sustained load, especially above 200°C |

| Poor Wear & Abrasion Resistance (Virgin PTFE) | Unsuitable for dynamic, high-friction applications |

| Not Melt-Processable | Limited to sintering, restricting complex shapes |

| Low Radiation Resistance | Degrades under gamma or electron-beam radiation |

Need high-performance PTFE components that overcome these limitations? KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, using filled and reinforced PTFE compounds to enhance wear resistance, stiffness, and creep performance. Let us help you select the right material for your application—contact our experts today for a tailored solution!

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the molecular characteristics of PTFE? Unlocking the Secrets of Its Unmatched Performance

- What are the mechanical properties of filled PTFE? Enhanced Wear Resistance and Strength for Demanding Applications

- What are the dielectric properties of PTFE? The Ultimate Insulator for Demanding Applications

- What are the different types of Teflon coatings and their features? Choose the Right Fluoropolymer for Your Application

- In which industries is PTFE/Teflon commonly used? Discover Its Critical Role in High-Performance Applications

- What is the temperature range for using PTFE? Master Its Use from -200°C to +260°C

- What is the volume resistivity of PTFE and why is it significant? Unlock Superior Electrical Insulation

- Can PTFE be modified with additives? Enhance Performance for Demanding Applications