The primary types of Teflon gland packing are Pure PTFE, Graphite-Impregnated PTFE, PTFE/Aramid Hybrid, and Expanded PTFE. Each variation is engineered to solve a distinct set of operational challenges, from extreme chemical exposure to high-pressure and high-temperature applications. Understanding their differences is the key to achieving a reliable, long-lasting seal.

The core challenge is not simply knowing the types of Teflon packing, but matching a specific material composition to your unique operational demands. The right choice hinges on a clear understanding of your system's temperature, pressure, chemical environment, and equipment type.

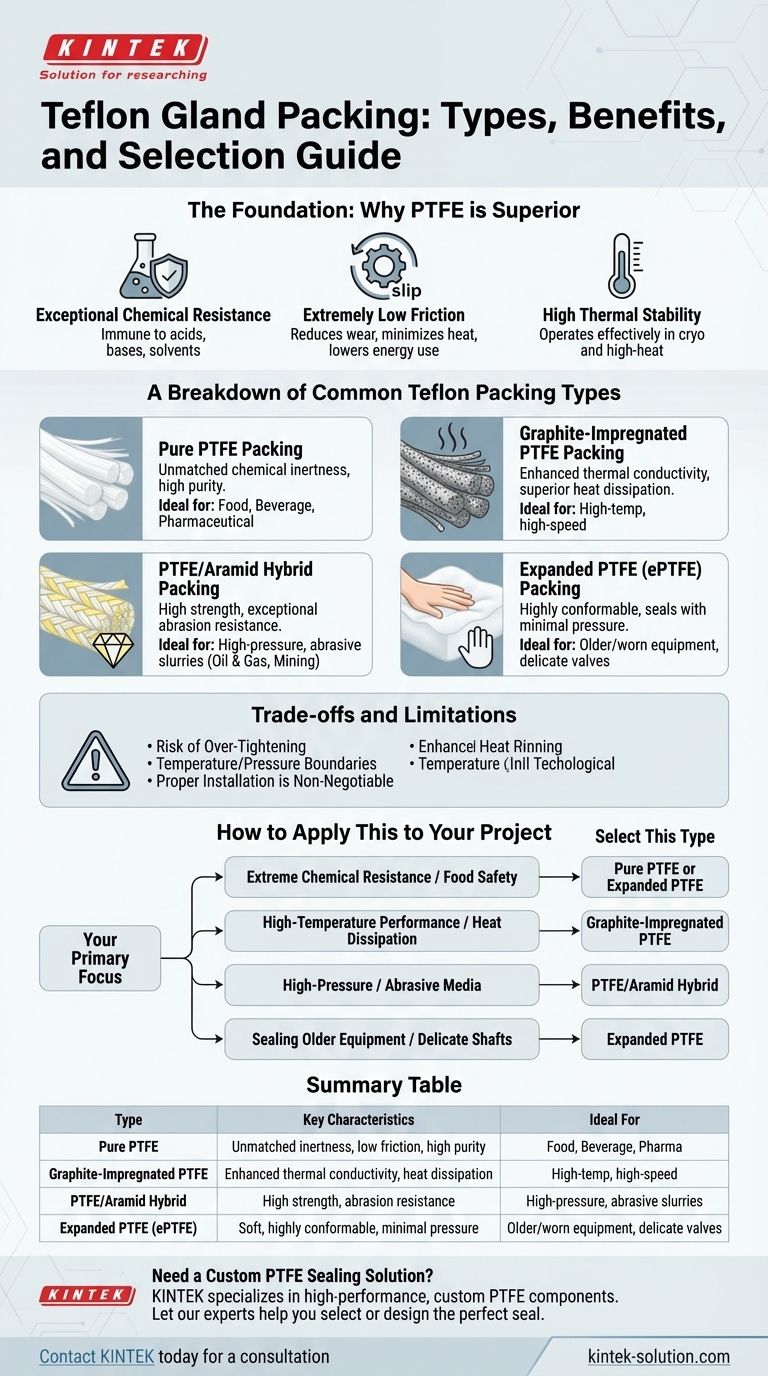

The Foundation: Why PTFE is a Superior Sealing Material

Before comparing the different types, it's essential to understand the properties of the core material, Polytetrafluoroethylene (PTFE), commonly known as Teflon.

Exceptional Chemical Resistance

PTFE is one of the most chemically inert materials available. It is virtually immune to acids, bases, solvents, and other corrosive media, making it an ideal choice for the chemical processing industry.

Extremely Low Friction

The material has an exceptionally low coefficient of friction. This property reduces wear on rotating shafts, minimizes heat generation, and lowers the energy required to operate equipment like pumps.

High Thermal Stability

PTFE can operate effectively across a wide range of temperatures. This stability ensures the packing maintains its integrity without degrading in both cryogenic and high-heat environments.

A Breakdown of Common Teflon Packing Types

Each type of Teflon packing incorporates these core benefits while adding specific enhancements for targeted applications.

Pure PTFE Packing

This is the most fundamental form, consisting of pure PTFE fibers. It is prized for its unmatched chemical inertness and cleanliness.

It is the standard choice for applications where purity is paramount, such as in the food, beverage, and pharmaceutical industries.

Graphite-Impregnated PTFE Packing

This type infuses graphite particles into the PTFE fibers. The graphite acts as a lubricant and dramatically improves thermal conductivity.

This packing is ideal for high-temperature and high-speed applications because it effectively dissipates heat away from the shaft, preventing overheating and seal failure.

PTFE/Aramid Hybrid Packing

This packing combines PTFE with aramid fibers (like Kevlar®), often braided together at the corners. The aramid provides exceptional strength and abrasion resistance.

It is designed for high-pressure applications and for sealing abrasive slurries, commonly found in the oil and gas, mining, and wastewater sectors.

Expanded PTFE (ePTFE) Packing

Made from a soft, highly conformable form of PTFE, this packing is excellent for creating a tight seal with minimal gland pressure.

Its flexibility makes it perfect for sealing older or slightly worn equipment and for applications requiring a delicate touch, including certain valves and food-grade machinery.

Understanding the Trade-offs and Limitations

While powerful, Teflon packing is not a universal solution. Acknowledging its limitations is crucial for successful implementation.

The Risk of Over-Tightening

One of the most common installation errors is over-compressing the packing. This can restrict necessary leakage for lubrication, cause excessive heat buildup, and score the equipment shaft.

Temperature and Pressure Boundaries

Pure PTFE has limitations regarding thermal expansion and creep (deformation under load). The addition of graphite or aramid is specifically meant to overcome these boundaries in more demanding applications.

Proper Installation is Non-Negotiable

The performance of any packing is heavily dependent on correct installation. This includes thoroughly cleaning the stuffing box, precisely cutting each packing ring, and tightening the gland follower evenly and sequentially.

How to Apply This to Your Project

Use your specific operational goals to guide your selection.

- If your primary focus is extreme chemical resistance or food safety: Choose Pure PTFE or Expanded PTFE for their inertness and purity.

- If your primary focus is high-temperature performance and heat dissipation: Select Graphite-Impregnated PTFE to protect your equipment in high-speed or high-heat services.

- If your primary focus is high-pressure or abrasive media: A PTFE/Aramid Hybrid offers the necessary strength and durability to prevent extrusion and wear.

- If your primary focus is sealing older equipment or delicate shafts: Use Expanded PTFE for its excellent conformability and ability to seal with minimal pressure.

Choosing the correct gland packing is a critical step in ensuring equipment reliability and operational safety.

Summary Table:

| Type of Teflon Packing | Key Characteristics | Ideal For |

|---|---|---|

| Pure PTFE | Unmatched chemical inertness, low friction, high purity | Food, Beverage, Pharmaceutical industries |

| Graphite-Impregnated PTFE | Enhanced thermal conductivity, superior heat dissipation | High-temperature, high-speed applications |

| PTFE/Aramid Hybrid | High strength, excellent abrasion resistance | High-pressure systems, abrasive slurries (Oil & Gas, Mining) |

| Expanded PTFE (ePTFE) | Soft, highly conformable, seals with minimal pressure | Older/worn equipment, delicate valves, food-grade machinery |

Need a Custom PTFE Sealing Solution?

Choosing the right gland packing is critical for your equipment's reliability and safety. KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver precision production and custom fabrication from prototypes to high-volume orders. Let our experts help you select or design the perfect seal for your specific temperature, pressure, and chemical requirements.

Contact KINTEK today for a consultation to enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the thermal properties of PTFE balls? Unlock Extreme Temperature Performance

- Which machining techniques are suitable for creating rough edges on PTFE? Master CNC Milling for Controlled Textures

- What are the advantages of PTFE envelope gaskets? Achieve Superior Chemical Sealing & Purity

- How does Teflon benefit the construction industry? Building Safer, More Durable Structures

- What other factors influence the CNC machining quality of PTFE parts? Master Material, Environment & Skill

- What are the different types of washers made from Teflon sheets? Choose the Right PTFE Washer for Your Application

- How do Teflon-encapsulated O-Rings benefit the food and beverage industry? Ensure Superior Sealing and Hygiene

- What are the advantages of PTFE in chemically aggressive environments? Unmatched Chemical Resistance & Reliability