The primary advantage of PTFE in chemically aggressive environments is its near-universal chemical inertness. Polytetrafluoroethylene (PTFE) is a non-reactive polymer that does not degrade, swell, or corrode when exposed to the vast majority of industrial chemicals, including strong acids, bases, and solvents. This inherent stability, combined with its wide operating temperature range, ensures unparalleled material integrity and operational reliability in the most demanding conditions.

When selecting materials for harsh chemical service, the core challenge is mitigating the risk of material failure. PTFE's fundamental advantage is that it effectively eliminates chemical attack as a failure mode, providing a level of reliability and longevity that is difficult to achieve with other polymers.

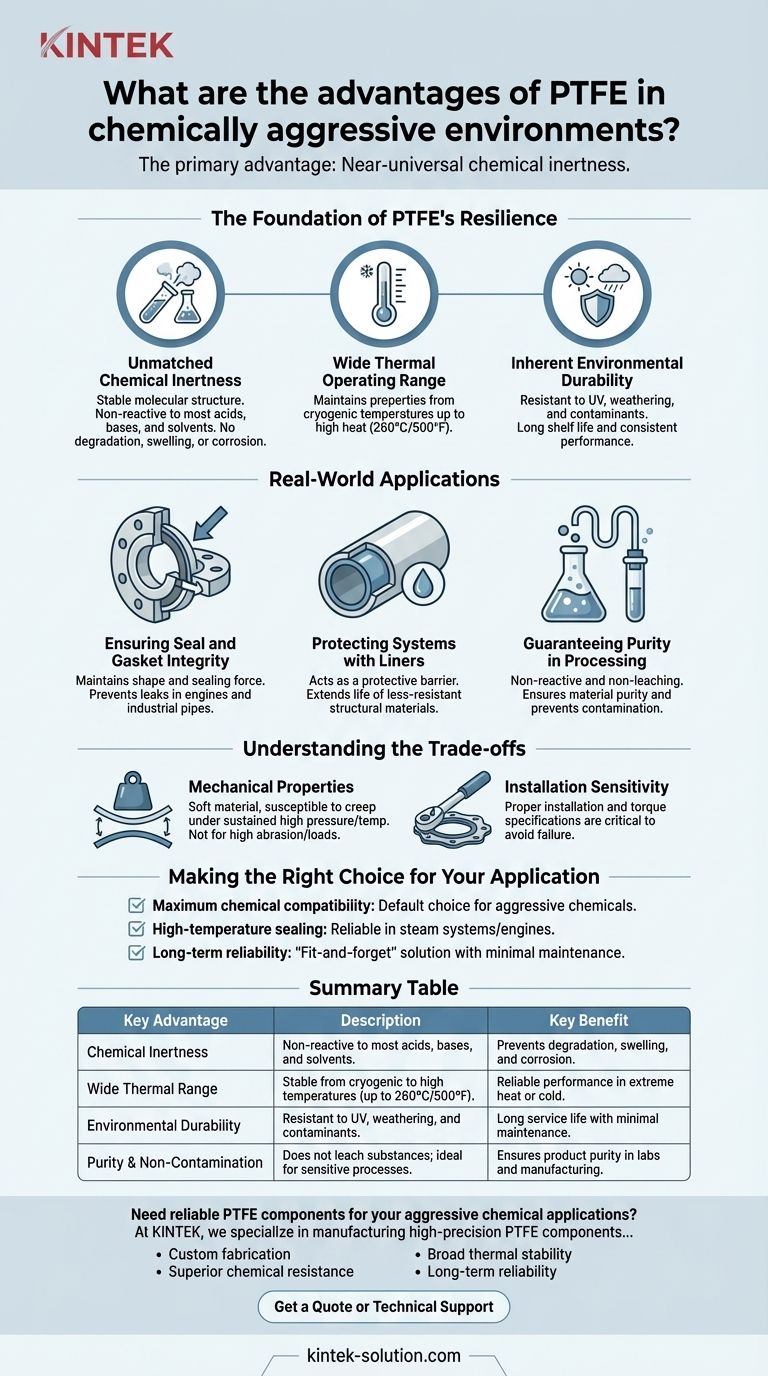

The Foundation of PTFE's Resilience

To understand why PTFE is a default choice for aggressive applications, it's essential to look at its core material properties. These characteristics work together to create a uniquely durable material.

Unmatched Chemical Inertness

PTFE's molecular structure, composed of strong carbon-fluorine bonds, is exceptionally stable. This makes it non-reactive to almost every chemical substance.

As a result, it will not swell, crack, or weaken when used in piping, gaskets, or seals for chemical processing. This ensures both the integrity of the equipment and the purity of the medium being transported.

Wide Thermal Operating Range

Chemical resistance is often compromised by temperature, but PTFE maintains its properties across a broad thermal spectrum. It remains stable and effective from cryogenic temperatures up to high-heat applications.

This makes it exceptionally reliable for components like gaskets in steam systems or seals in high-powered engines, where both chemical exposure and extreme temperatures are present.

Inherent Environmental Durability

Beyond direct chemical contact, PTFE is highly resistant to weathering and UV radiation. It is not affected by harsh environmental conditions or contaminants.

This property ensures a long shelf life and consistent performance over time, even in outdoor or otherwise challenging installations.

How These Properties Translate to Real-World Applications

The theoretical advantages of PTFE become tangible benefits across various industrial uses. Its properties directly solve common engineering challenges related to containment, sealing, and system protection.

Ensuring Seal and Gasket Integrity

In any sealed system, the gasket or seal is often the weakest point. PTFE gaskets and seals maintain their shape and sealing force without degrading from chemical attack.

This prevents leaks in critical applications like automotive engines handling aggressive fuels and oils or in industrial pipes carrying corrosive fluids.

Protecting Systems with Liners

PTFE can be used as a protective barrier to shield other components from chemical attack. It is often supplied as a bore liner or "envelope" for gaskets.

This design allows a less-resistant structural material to be used for the main body of a part, while the PTFE liner provides the necessary chemical protection, extending the life of the entire assembly.

Guaranteeing Purity in Processing

In laboratory or chemical manufacturing settings, preventing contamination is paramount. Because PTFE is non-reactive and doesn't leach substances, it's an ideal material for tubing, containers, and equipment linings.

This ensures that the material being processed remains pure and that the equipment itself is not compromised by the process medium.

Understanding the Trade-offs

While its chemical and thermal properties are exceptional, no material is perfect for every situation. An objective assessment requires understanding PTFE's limitations.

Mechanical Properties

PTFE is a relatively soft material. It can be susceptible to creep, or cold flow, under sustained high pressure, particularly at elevated temperatures.

For applications requiring high abrasion resistance or structural rigidity under heavy loads, other engineered plastics or filled grades of PTFE might be more suitable.

Installation Sensitivity

The effectiveness of PTFE components, particularly gaskets, depends heavily on proper installation.

Overtightening a PTFE gasket can cause it to extrude from the flange, leading to a loss of sealing pressure and eventual failure. Following correct torque specifications is critical.

Upfront Cost

PTFE is often a premium-priced polymer. Its initial cost can be higher than many standard elastomers or plastics.

However, this cost is frequently justified by a lower total cost of ownership, as its durability reduces the need for frequent inspection, maintenance, and replacement.

Making the Right Choice for Your Application

Selecting PTFE is an engineering decision based on specific operational demands. Use the following points as a guide for your evaluation.

- If your primary focus is maximum chemical compatibility: PTFE is the default choice for sealing, lining, or conveying the most aggressive industrial chemicals where other materials would quickly fail.

- If your primary focus is high-temperature sealing: PTFE's thermal stability ensures a reliable seal in environments like steam systems or engines where other polymers would degrade or harden.

- If your primary focus is long-term reliability with minimal maintenance: The combination of chemical, thermal, and environmental resistance makes PTFE a "fit-and-forget" solution that lowers operational risk and ownership cost over the component's lifetime.

Ultimately, choosing PTFE is an investment in operational certainty for your most critical and aggressive applications.

Summary Table:

| Key Advantage | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Non-reactive to most acids, bases, and solvents. | Prevents degradation, swelling, and corrosion. |

| Wide Thermal Range | Stable from cryogenic to high temperatures (up to 260°C/500°F). | Reliable performance in extreme heat or cold. |

| Environmental Durability | Resistant to UV, weathering, and contaminants. | Long service life with minimal maintenance. |

| Purity & Non-Contamination | Does not leach substances; ideal for sensitive processes. | Ensures product purity in labs and manufacturing. |

Need reliable PTFE components for your aggressive chemical applications?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, gaskets, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment maintains integrity, purity, and longevity in the most demanding environments.

✅ Custom fabrication from prototypes to high-volume orders

✅ Superior chemical resistance for aggressive media

✅ Broad thermal stability for extreme temperatures

✅ Long-term reliability with minimal maintenance

Contact us today to discuss your specific requirements and let our solutions enhance your operational certainty.

Get a Quote or Technical Support

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE