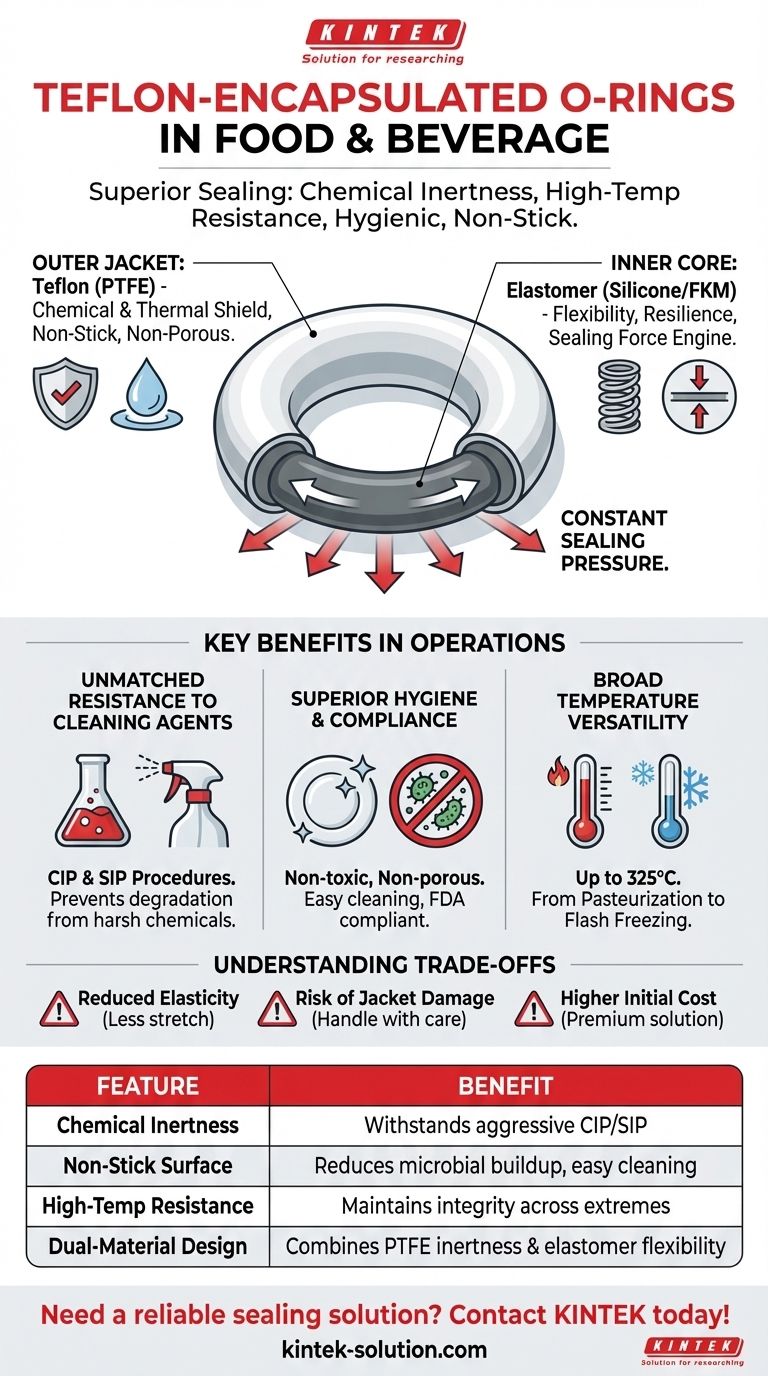

In the food and beverage industry, Teflon-encapsulated O-rings provide a superior sealing solution due to their unique combination of chemical inertness, high-temperature resistance, and hygienic, non-stick properties. This performance comes from a dual-material design that leverages the strengths of a tough outer jacket and a flexible inner core, ensuring both product safety and operational reliability.

The critical advantage of Teflon-encapsulated O-rings is not a single feature, but the fusion of two materials. They combine the impenetrable, non-stick surface of a Teflon (PTFE) jacket with the flexible, reliable sealing pressure of an inner elastomeric core, solving the core challenge of maintaining seal integrity in harsh, hygienic environments.

The Engineering Behind the Seal: A Two-Part System

To understand their benefit, you must first understand their construction. These are not monolithic seals; they are a composite solution designed to overcome the limitations of individual materials.

The Outer Jacket: Your Chemical and Thermal Shield

The external layer is a thin jacket of seamless Teflon (PTFE). This material is responsible for the O-ring's interaction with its environment.

Teflon is exceptionally non-reactive, providing a barrier that is almost completely inert to the strong acids, bases, and solvents used in aggressive Clean-in-Place (CIP) and Sterilize-in-Place (SIP) procedures.

Its surface is also non-stick and non-porous, which prevents the buildup of food particles and microorganisms, making cleaning and sanitization far more effective.

The Inner Core: The Engine of the Seal

Inside the jacket is an energizing core made from an elastomer, typically silicone or FKM (Viton®).

This core provides the flexibility, resilience, and memory that a solid Teflon ring would lack. It's the engine that provides the constant outward pressure—the "sealing force"—needed to maintain a tight seal against a housing.

Why Encapsulation is Crucial

The encapsulation design is the key. It protects the vulnerable elastomeric core from direct contact with process fluids and harsh cleaning chemicals.

A standard silicone or FKM O-ring would degrade quickly under these conditions, but when shielded by the Teflon jacket, its physical sealing properties are preserved for a much longer operational life.

Key Benefits in Food and Beverage Operations

This composite design directly translates into tangible advantages for food processing, packaging, and handling equipment.

Unmatched Resistance to Cleaning Agents

The most significant benefit is the seal's ability to withstand repeated exposure to aggressive CIP and SIP chemicals.

The Teflon jacket's chemical inertness prevents the swelling, hardening, or general degradation that destroys standard elastomer seals, which in turn prevents equipment failure and costly downtime.

Superior Hygiene and Compliance

Food safety is non-negotiable. The non-toxic and non-porous surface of the Teflon jacket does not harbor bacteria or contaminants.

This non-stick quality ensures that equipment can be cleaned to the highest hygienic standards with minimal effort, aiding compliance with regulations from bodies like the FDA.

Broad Temperature Versatility

Food and beverage processes often involve extreme temperature swings, from high-heat pasteurization and steam sterilization to low-temperature flash freezing.

Teflon's excellent thermal stability (handling temperatures up to 325°C) allows these O-rings to maintain seal integrity across a vast operational range where other materials would fail.

Understanding the Trade-offs

While highly effective, this design is not without its considerations. Objectivity requires acknowledging its specific limitations.

Reduced Elasticity

The Teflon jacket, while thin, is more rigid than a standard elastomer. This means encapsulated O-rings have less flexibility and "stretch."

They require more care during installation to avoid damaging the jacket and may not be suitable for applications requiring a very high degree of dynamic movement.

Risk of Jacket Damage

The integrity of the seal depends entirely on the seamless Teflon jacket. If this jacket is scratched, nicked, or improperly installed, the core can be exposed to the process media.

Once the core is exposed, it will degrade just like a standard O-ring, leading to premature seal failure.

Higher Initial Cost

Teflon-encapsulated O-rings are a premium sealing solution. Their initial procurement cost is higher than that of standard silicone or FKM O-rings.

This cost must be weighed against the significant long-term benefits of extended service life, reduced maintenance, minimized downtime, and enhanced product safety.

Making the Right Choice for Your Application

Selecting the right seal depends on identifying your most critical operational challenge.

- If your primary focus is preventing contamination: The non-porous, non-stick Teflon surface is your best defense against microbial buildup and ensures effective sanitization.

- If your primary focus is withstanding aggressive cleaning cycles: The chemical inertness of the PTFE jacket protects the seal from degradation caused by caustic CIP and SIP agents.

- If your primary focus is operational longevity: This design extends the O-ring's lifespan by protecting the sensitive elastomeric core, reducing downtime and maintenance costs.

By understanding this dual-material design, you can confidently specify a sealing solution that ensures both product safety and operational reliability.

Summary Table:

| Feature | Benefit |

|---|---|

| Chemical Inertness | Withstands aggressive CIP/SIP chemicals, preventing degradation. |

| Non-Stick Surface | Reduces microbial buildup, ensuring easy cleaning and compliance. |

| High-Temperature Resistance | Maintains seal integrity from pasteurization to freezing. |

| Dual-Material Design | Combines PTFE's inertness with elastomer flexibility for reliable sealing. |

Need a reliable sealing solution for your food and beverage equipment?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom Teflon-encapsulated O-rings. Our precision-engineered seals are designed to withstand harsh chemicals, extreme temperatures, and rigorous hygiene standards—ensuring your operations run smoothly with minimal downtime.

Whether you need prototypes or high-volume orders, we deliver solutions tailored to the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss your specific requirements and enhance your equipment's reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials