The primary advantage of a PTFE envelope gasket is its ability to deliver the exceptional chemical resistance and purity of solid PTFE without sacrificing the mechanical strength and resilience of a traditional gasket material. This unique composite design provides a chemically inert sealing surface that is non-contaminating, durable, and capable of operating across a wide temperature range, making it a versatile solution for demanding applications.

The core challenge in many industrial sealing applications is finding a material that is both chemically inert and mechanically robust. A PTFE envelope gasket solves this by combining a resilient core insert with a thin, protective PTFE "envelope," offering the chemical purity of PTFE with the structural integrity required for a reliable, long-lasting seal.

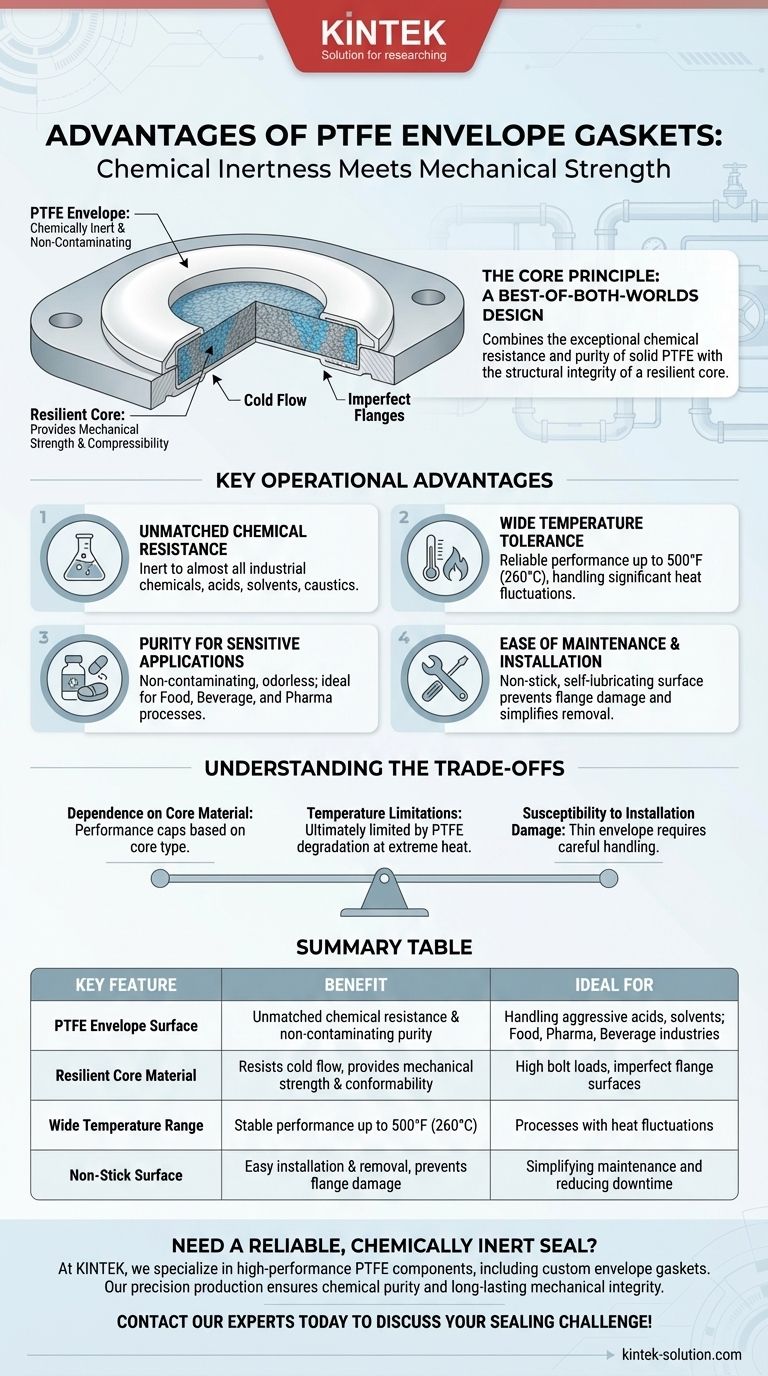

The Core Principle: A Best-of-Both-Worlds Design

The genius of the PTFE envelope gasket lies in its composite structure. It isn't a single material, but a clever combination designed to overcome the limitations of its individual components.

Combining Chemical Inertness with Mechanical Strength

A solid gasket made entirely of PTFE would be chemically resistant but also soft and prone to deforming under pressure.

By contrast, an envelope gasket uses a stronger, more resilient core material (like non-asbestos, rubber, or corrugated metal) to provide mechanical strength and compressibility.

This core is then enclosed in a thin "envelope" of PTFE, ensuring that only the chemically inert PTFE surface comes into contact with the process media.

Preventing Cold Flow and Extrusion

A common failure mode for solid PTFE gaskets is cold flow, where the material slowly deforms or "creeps" outward under the pressure of the flange bolts.

The internal core of an envelope gasket provides structural support, resisting this creep and ensuring the gasket maintains a tight seal over time, even with high bolt loading.

Adapting to Imperfect Flanges

The compressible nature of the inner core material allows the gasket to conform better to minor imperfections, scratches, or slight warping in flange faces.

This adaptability results in a more reliable and forgiving seal compared to a more rigid gasket material.

Key Operational Advantages

This unique design translates into several distinct operational benefits that make PTFE envelope gaskets a superior choice in specific environments.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes envelope gaskets an excellent choice for sealing flanges in systems that handle aggressive acids, solvents, caustics, and other corrosive media.

Wide Temperature Tolerance

These gaskets can perform reliably across a broad temperature spectrum, typically up to 500°F (260°C), depending on the core material selected.

This stability is crucial for processes that experience significant heat fluctuations, ensuring the seal remains intact.

Purity for Sensitive Applications

Because the PTFE surface is non-contaminating, odorless, and non-absorbent, these gaskets are ideal for the food, beverage, and pharmaceutical industries.

They ensure that the process media remains pure and free from contamination, meeting strict regulatory standards.

Ease of Maintenance and Installation

PTFE has an extremely low coefficient of friction, creating a non-stick, self-lubricating surface.

This property prevents the gasket from adhering to the flange faces, which simplifies removal during maintenance and reduces the risk of damaging the flange surfaces.

Understanding the Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. An objective assessment requires understanding their limitations.

Dependence on the Core Material

The gasket's overall performance, particularly its pressure and temperature limits, is heavily dependent on the core material chosen. A soft rubber core will have a very different performance profile than a corrugated steel core.

Temperature Limitations

While the temperature range is wide, it is ultimately capped by the performance of PTFE itself, which begins to degrade at extremely high temperatures where a metallic gasket might still perform.

Susceptibility to Installation Damage

The PTFE envelope is relatively thin. Careless handling during installation can lead to scratches or punctures, which would compromise the gasket's chemical barrier and lead to premature failure.

Making the Right Choice for Your Application

Selecting the right gasket requires matching its advantages to your primary operational goal.

- If your primary focus is handling aggressive chemicals or corrosive media: The inert PTFE surface provides the robust chemical barrier you need to ensure both safety and equipment longevity.

- If your primary focus is purity for food, beverage, or pharmaceutical processes: Its non-contaminating and FDA-compliant properties make it the ideal choice to protect product integrity.

- If your primary focus is a reliable seal on older or slightly uneven flange surfaces: The combination of a compressible core and a stable PTFE shell offers superior adaptability and a more forgiving seal.

Ultimately, a PTFE envelope gasket is the definitive choice when you need absolute chemical resilience without compromising the mechanical performance of the seal.

Summary Table:

| Key Feature | Benefit | Ideal For |

|---|---|---|

| PTFE Envelope Surface | Unmatched chemical resistance & non-contaminating purity | Handling aggressive acids, solvents; Food, Pharma, Beverage industries |

| Resilient Core Material | Resists cold flow, provides mechanical strength & conformability | High bolt loads, imperfect flange surfaces |

| Wide Temperature Range | Stable performance up to 500°F (260°C) | Processes with heat fluctuations |

| Non-Stick Surface | Easy installation & removal, prevents flange damage | Simplifying maintenance and reducing downtime |

Need a reliable, chemically inert seal for your critical application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom envelope gaskets. Our precision production ensures you get a gasket that delivers the chemical purity of PTFE with the mechanical integrity required for long-lasting performance in semiconductor, medical, laboratory, and industrial settings.

Whether you need prototypes or high-volume orders, we can fabricate a solution tailored to your specific flange and media requirements.

Contact our experts today to discuss your sealing challenge and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications