In short, Teflon benefits the construction industry by providing a unique combination of properties that enhance the durability, reliability, and longevity of critical components. Its ability to reduce friction, repel water and chemicals, and insulate against electricity and heat makes it a versatile problem-solver for everything from massive bridge bearings to tiny screws.

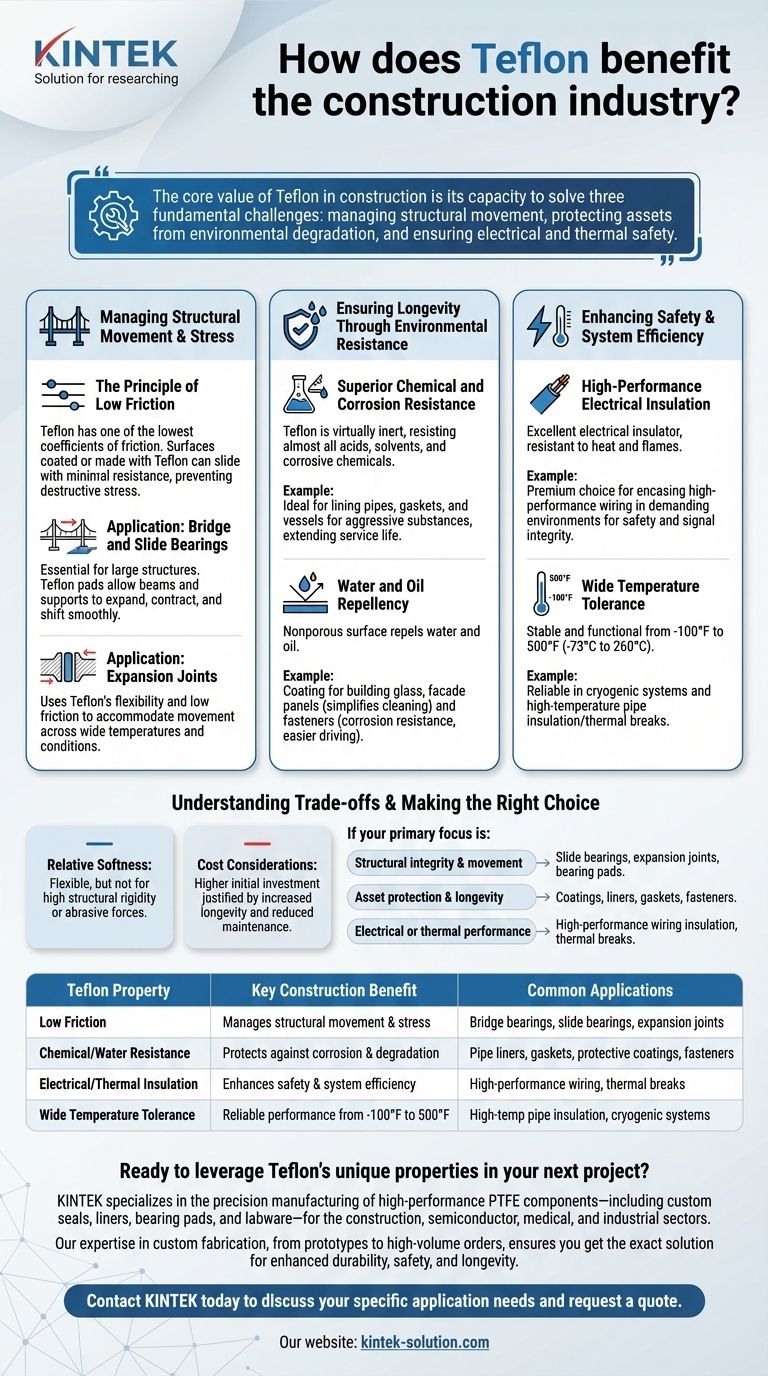

The core value of Teflon in construction is not a single benefit, but its capacity to solve three fundamental challenges: managing structural movement, protecting assets from environmental degradation, and ensuring electrical and thermal safety.

Managing Movement and Structural Stress

Large structures are not static; they move due to thermal expansion, wind, and seismic activity. Teflon's properties are uniquely suited to manage this movement safely and predictably.

The Principle of Low Friction

Teflon, or Polytetrafluoroethylene (PTFE), has one of the lowest coefficients of friction of any known solid material.

This means surfaces coated or made with Teflon can slide against each other with minimal resistance, preventing the build-up of destructive stress.

Application: Bridge and Slide Bearings

This low-friction property is essential in bridge bearings and slide bearings for large buildings.

These components are pads of Teflon that sit between structural elements, allowing beams and supports to expand, contract, and shift smoothly without damaging the structure.

Application: Expansion Joints

Similarly, expansion joints in buildings, pipelines, and bridges use Teflon's flexibility and low-friction nature to accommodate movement. This ensures the integrity of the structure across a wide range of temperatures and conditions.

Ensuring Longevity Through Environmental Resistance

Structures and their components are constantly under attack from moisture, chemicals, and corrosion. Teflon creates a highly effective protective barrier.

Superior Chemical and Corrosion Resistance

Teflon is virtually inert, meaning it resists almost all acids, solvents, and corrosive chemicals.

This makes it an ideal material for lining pipes, gaskets, and vessels that handle aggressive substances, significantly extending their service life.

Water and Oil Repellency

The material's surface is nonporous and repels both water and oil.

When used as a coating on building glass or facade panels, it simplifies cleaning and maintenance. On fasteners like screws, it provides corrosion resistance and makes them easier to drive by reducing friction.

Enhancing Safety and System Efficiency

Beyond structural applications, Teflon plays a critical role in the mechanical and electrical systems within a building.

High-Performance Electrical Insulation

Teflon is an excellent electrical insulator that is also resistant to heat and flames.

This makes it a premium choice for encasing or coating high-performance wiring, especially in demanding environments where safety and signal integrity are paramount.

Wide Temperature Tolerance

It remains stable and functional across an exceptionally broad temperature range, typically from -100°F to 500°F (-73°C to 260°C).

This allows it to be used reliably in applications ranging from cryogenic systems to high-temperature pipe insulation and thermal breaks.

Understanding the Trade-offs

While incredibly useful, Teflon is not a universal solution. Understanding its limitations is key to using it effectively.

Relative Softness

Teflon is a relatively soft material, which provides the flexibility needed for gaskets and bearings. However, it is not suitable for applications requiring high structural rigidity or resistance to sharp, abrasive forces on its own.

Cost Considerations

As a high-performance polymer, Teflon and its application processes are often more expensive than commodity plastics or traditional materials. The investment is justified by increased longevity and reduced maintenance costs over the asset's lifecycle.

Making the Right Choice for Your Application

To leverage Teflon effectively, align its specific properties with your project's primary goal.

- If your primary focus is structural integrity and movement: Prioritize Teflon's use in slide bearings, expansion joints, and bearing pads to manage thermal and seismic forces.

- If your primary focus is asset protection and longevity: Use Teflon coatings and liners for pipelines, gaskets, and fasteners to prevent corrosion and chemical degradation.

- If your primary focus is electrical or thermal performance: Specify Teflon for high-performance wiring insulation and for creating effective thermal breaks to improve energy efficiency.

By understanding these distinct applications, you can strategically deploy this remarkable material to build safer, more durable, and more reliable structures.

Summary Table:

| Teflon Property | Key Construction Benefit | Common Applications |

|---|---|---|

| Low Friction | Manages structural movement & stress | Bridge bearings, slide bearings, expansion joints |

| Chemical/Water Resistance | Protects against corrosion & degradation | Pipe liners, gaskets, protective coatings, fasteners |

| Electrical/Thermal Insulation | Enhances safety & system efficiency | High-performance wiring, thermal breaks |

| Wide Temperature Tolerance | Reliable performance from -100°F to 500°F | High-temp pipe insulation, cryogenic systems |

Ready to leverage Teflon's unique properties in your next project?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—including custom seals, liners, bearing pads, and labware—for the construction, semiconductor, medical, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact solution for enhanced durability, safety, and longevity.

Contact KINTEK today to discuss your specific application needs and request a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability