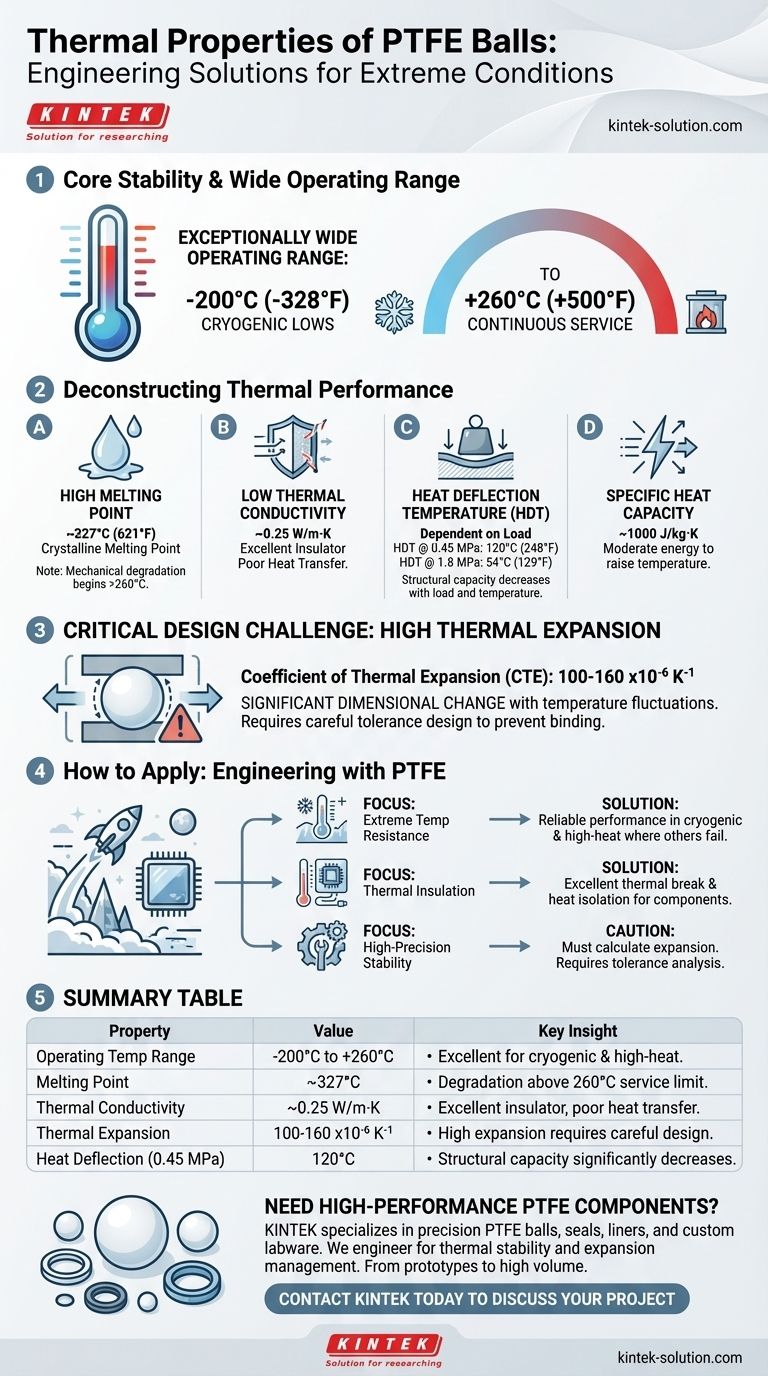

At its core, Polytetrafluoroethylene (PTFE) is one of the most thermally stable polymers available. PTFE balls exhibit an exceptionally wide operating temperature range, maintaining their integrity from cryogenic lows of -200°C up to continuous service temperatures of 260°C (500°F). Key thermal properties include a low thermal conductivity of approximately 0.25 W/m·K, making it an excellent insulator, and a high melting point of around 327°C (621°F).

While PTFE's performance at temperature extremes is remarkable, its primary design limitation is a high coefficient of thermal expansion. This means it changes size significantly with temperature, a critical factor that must be accounted for in any high-precision application.

Deconstructing Thermal Performance

Understanding the specific thermal metrics of PTFE is essential for determining its suitability for your application. Each property tells a different part of the story about how the material behaves when exposed to heat or cold.

A Vast Operating Temperature Range

PTFE maintains its excellent physical and chemical properties across a massive temperature spectrum. Its continuous service temperature is reliably cited as -200°C to +260°C (-328°F to +500°F).

This makes it a premier choice not only for high-heat applications but also for cryogenic systems where other plastics would become brittle and fail.

High Melting Point vs. Service Temperature

The crystalline melting point of PTFE is approximately 327°C (621°F). It's important to distinguish this from the service temperature.

While the material doesn't melt until this point, its mechanical properties begin to degrade above the 260°C service limit. Pushing past this limit risks material failure and the release of hazardous fumes.

Low Thermal Conductivity

With a thermal conductivity of just 0.25 W/m·K, PTFE is an excellent thermal insulator.

This means it is very poor at transferring heat. This property is highly valuable for applications requiring thermal barriers or electrical components where heat buildup must be isolated.

Heat Deflection Temperature (HDT)

The HDT indicates the temperature at which a material deforms under a specific load. For PTFE, this value is highly dependent on the applied stress.

The HDT is 120°C (248°F) under a low load of 0.45 MPa but drops to just 54°C (129°F) under a higher load of 1.8 MPa. This is a critical metric for any structural part that must bear weight at elevated temperatures.

Specific Heat Capacity

PTFE has a specific heat capacity of approximately 1000 J/kg·K. This value describes the amount of energy required to raise the temperature of the material.

While not as critical as other metrics for most applications, it indicates that PTFE requires a moderate amount of thermal energy to change its temperature.

Understanding the Trade-offs: Thermal Expansion

The single most important thermal property to consider in design is PTFE's high coefficient of thermal expansion. Ignoring this can lead to catastrophic component failure.

The Challenge of Dimensional Stability

PTFE has a coefficient of thermal expansion between 100 and 160 x10⁻⁶ K⁻¹.

In simple terms, this is very high for a plastic. It means that PTFE balls will expand and contract significantly as the ambient temperature changes.

Practical Implications for Design

This expansion must be accounted for in applications with tight tolerances. For example, a PTFE ball used as a check valve or bearing must have enough clearance in its housing to accommodate thermal expansion, or it could seize up and fail.

Engineers must calculate the expected dimensional change across the full operating temperature range to ensure proper function.

How to Apply This to Your Project

Your decision to use PTFE balls should be based on a clear understanding of these properties in the context of your specific goals.

- If your primary focus is extreme temperature resistance: PTFE is an elite material, performing reliably in both cryogenic and high-heat environments where most other polymers fail.

- If your primary focus is thermal insulation: PTFE's low thermal conductivity makes it an excellent choice for creating thermal breaks or isolating components from heat.

- If your primary focus is high-precision dimensional stability: You must proceed with caution. The high thermal expansion of PTFE requires careful design and tolerance analysis to prevent binding or failure.

By leveraging PTFE's unparalleled thermal stability while respecting its expansion characteristics, you can engineer a highly reliable solution.

Summary Table:

| Property | Value | Key Insight |

|---|---|---|

| Operating Temperature Range | -200°C to +260°C | Excellent for cryogenic and high-heat environments. |

| Melting Point | ~327°C (621°F) | Mechanical properties degrade above 260°C service limit. |

| Thermal Conductivity | ~0.25 W/m·K | Excellent thermal insulator, poor heat transfer. |

| Coefficient of Thermal Expansion | 100-160 x10⁻⁶ K⁻¹ | High expansion requires careful design for precision parts. |

| Heat Deflection Temp (HDT @ 0.45 MPa) | 120°C (248°F) | Structural capacity under load decreases significantly with temperature. |

Need High-Performance PTFE Components for Demanding Environments?

At KINTEK, we specialize in manufacturing precision PTFE components, including balls, seals, liners, and custom labware. We understand that leveraging PTFE's exceptional thermal stability—from cryogenic to high-temperature applications—requires precise engineering to manage its high thermal expansion.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide custom fabrication from prototypes to high-volume orders, ensuring your components perform reliably under extreme conditions.

Contact KINTEK today to discuss your project's thermal requirements and get a solution engineered for success.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What advantages does carbon-graphite-filled PTFE offer? Enhance Wear Resistance & Thermal Management

- Why are PTFE envelope gaskets suitable for FDA applications? Ensuring Purity and Compliance

- How do PTFE control valves contribute to industrial safety? Prevent Leaks & Ensure Process Integrity

- What material was considered as an alternative to Turcite for making fork bushes, and why? Uncover the PTFE vs. Acetal Trade-off

- How can PTFE rotary shaft seals contribute to operational efficiency and cost savings? Maximize Uptime & Reduce Costs

- What is PTFE packing and what are its primary characteristics? Master Sealing for Extreme Conditions

- What should be considered regarding surface compatibility when using PTFE washers? Ensuring a Reliable Seal in Demanding Applications

- What material are PTFE ring gaskets made from? Unlock Superior Chemical & Thermal Sealing