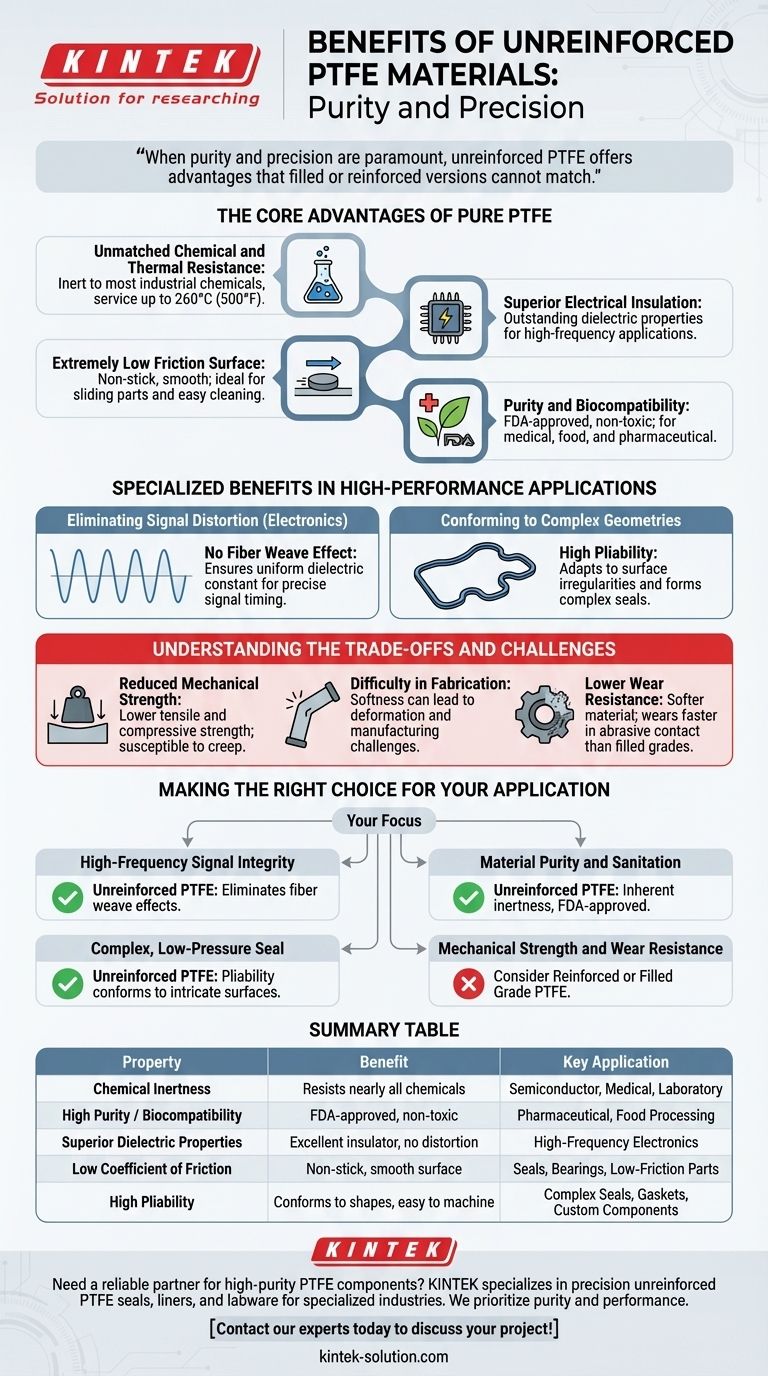

When purity and precision are paramount, unreinforced Polytetrafluoroethylene (PTFE) offers a unique set of advantages that filled or reinforced versions cannot match. Its primary benefits stem from its pure composition, providing exceptional chemical inertness, a very low coefficient of friction, superior dielectric properties for high-frequency electronics, and a high degree of pliability ideal for forming complex seals and shapes.

Choosing unreinforced PTFE is a strategic decision for applications where material purity and electrical signal integrity are non-negotiable. This choice prioritizes these specific benefits over the mechanical strength and dimensional stability found in reinforced alternatives.

The Core Advantages of Pure PTFE

The fundamental benefits of unreinforced PTFE come from its pure, unadulterated chemical structure. It is the baseline from which all other PTFE grades are developed.

Unmatched Chemical and Thermal Resistance

Unreinforced PTFE is one of the most chemically inert polymers known. It resists nearly all industrial chemicals and solvents, making it invaluable for use in harsh environments.

It also operates over a vast temperature range, with a high melting point around 620°F (327°C) and a continuous service temperature up to 260°C.

Superior Electrical Insulation

PTFE possesses outstanding dielectric properties, meaning it is an excellent electrical insulator. This is critical in electronic components where signal isolation is necessary.

Its consistency as an insulator is particularly valued in high-frequency applications, where the introduction of other materials (like glass fibers) can alter performance.

Extremely Low Friction Surface

The material has one of the lowest coefficients of friction of any solid, giving it an exceptionally non-stick and smooth surface.

This is highly beneficial for sliding or rotating parts where minimizing resistance is key, or for surfaces that require frequent and easy cleaning.

Purity and Biocompatibility

Because it contains no fillers or reinforcing agents, unreinforced PTFE is inherently pure. Many grades are FDA-approved and non-toxic.

This makes it a default choice for applications in the food processing, medical, and pharmaceutical industries where preventing contamination is a primary concern.

Specialized Benefits in High-Performance Applications

Beyond its general properties, the lack of reinforcement gives unreinforced PTFE distinct advantages in specific, highly technical fields.

Eliminating Signal Distortion in Electronics

In high-frequency systems like advanced radar, the fiber weave in reinforced laminates can cause signal skew and inconsistency. Unreinforced PTFE laminates eliminate this fiber weave effect.

This ensures a uniform dielectric constant, which is critical for components like phase-matched antennas that rely on precise and predictable signal timing.

Conforming to Complex Geometries

The pliability and compressibility of unreinforced PTFE are significant assets in sealing applications. It can easily adapt to surface irregularities and form complex gasket shapes.

This softness also allows it to be machined to very tight tolerances, creating intricate components that would be more difficult to produce with harder, reinforced materials.

Understanding the Trade-offs and Challenges

The decision to use unreinforced PTFE requires a clear understanding of its limitations, which are the direct inverse of its strengths.

Reduced Mechanical Strength

The primary trade-off is a lack of rigidity and strength. Unreinforced PTFE is susceptible to creep (deformation under load) and has much lower tensile and compressive strength than filled grades.

It is not suitable for applications that require significant load-bearing or structural integrity.

Difficulty in Fabrication

While pliable, the material's softness can be a manufacturing challenge. It can be difficult to handle and is prone to deformation during production.

In multi-layer circuit boards, this lack of rigidity can lead to layer-to-layer misregistration and misalignment in drill holes if not handled by highly experienced fabricators.

Lower Wear Resistance

Although it has low friction, pure PTFE is a relatively soft material. In applications with significant abrasive contact, it will wear down more quickly than PTFE grades filled with materials like carbon or bronze.

Making the Right Choice for Your Application

Your choice depends entirely on the primary demands of your project. The unique profile of unreinforced PTFE makes it the best solution for some goals and unsuitable for others.

- If your primary focus is high-frequency signal integrity: Unreinforced PTFE is the superior choice to eliminate fiber weave effects and ensure consistent dielectric performance.

- If your primary focus is material purity and sanitation: The inherent inertness and FDA-approved status of unreinforced PTFE make it ideal for medical, food, and pharmaceutical applications.

- If your primary focus is a complex, low-pressure seal: The pliability and compressibility of unreinforced PTFE allow it to conform perfectly to intricate surfaces.

- If your primary focus is mechanical strength and wear resistance: You must consider a reinforced or filled grade of PTFE, as the unreinforced version lacks the necessary rigidity for load-bearing roles.

By understanding these distinct properties, you can leverage unreinforced PTFE not just as a material, but as a precise engineering solution.

Summary Table:

| Property | Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Resists nearly all chemicals | Semiconductor, Medical, Laboratory |

| High Purity / Biocompatibility | FDA-approved, non-toxic | Pharmaceutical, Food Processing |

| Superior Dielectric Properties | Excellent insulator, no signal distortion | High-Frequency Electronics |

| Low Coefficient of Friction | Non-stick, smooth surface | Seals, Bearings, Low-Friction Parts |

| High Pliability | Conforms to complex shapes, easy to machine | Complex Seals, Gaskets, Custom Components |

Need a reliable partner for high-purity PTFE components?

KINTEK specializes in manufacturing precision unreinforced PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and other specialized industries. We prioritize the material purity and performance your application demands.

Let us help you leverage the unique benefits of unreinforced PTFE—from prototypes to high-volume production.

Contact our experts today to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

People Also Ask

- What factors have contributed to the expansion of the global supply chain for Teflon machined parts? Key Drivers and Industry Insights

- What are the diameter tolerances for PTFE balls? A Guide to Precision vs. Standard Grades

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the benefits of PTFE mill-type envelope gaskets? Achieve Reliable Sealing in Harsh Chemical Environments

- What is the significance of valve design in preventing PTFE seat deformation? Ensure Long-Term Sealing Integrity

- How does a PTFE lined butterfly valve compare to other valve types? A Guide to Superior Sealing & Chemical Resistance

- How does low friction benefit mechanical systems using PTFE washers? Boost Efficiency & Lifespan

- What are the key features of PTFE reducing flanges? Superior Chemical Resistance and Leak-Proof Performance