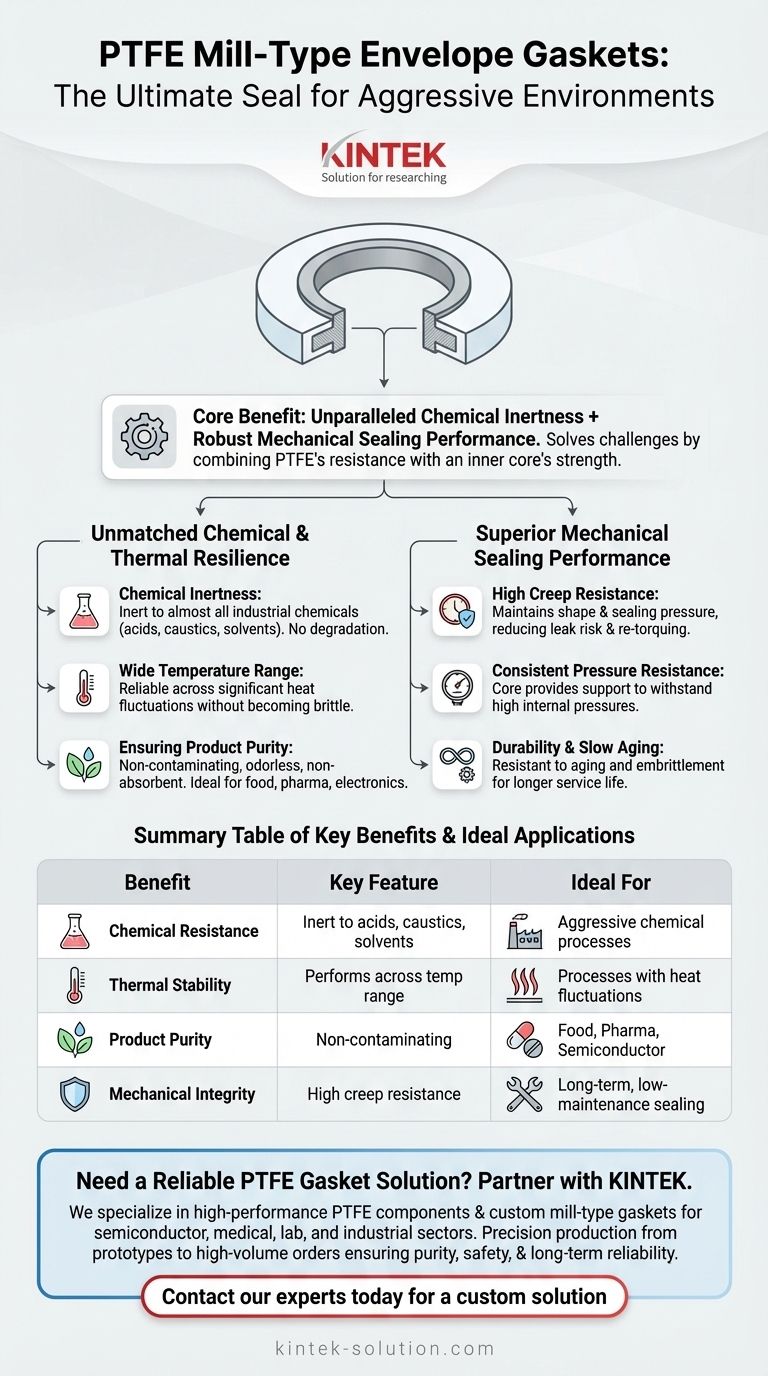

In essence, PTFE mill-type envelope gaskets provide a unique combination of extreme chemical inertness and robust mechanical sealing performance. Their core benefit is the ability to create a reliable, long-lasting seal in aggressive environments where other materials would quickly degrade, all while protecting the purity of the process media.

The central value of a PTFE envelope gasket is its ability to solve a difficult engineering challenge: it combines the unparalleled chemical resistance of PTFE with the mechanical strength and resilience of an inner core material, creating a seal that is both durable and non-contaminating.

Unmatched Chemical and Thermal Resilience

The primary reason engineers specify PTFE is for its remarkable ability to withstand harsh conditions. This resilience is the foundation of the gasket's performance.

The Advantage of Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals. This means it will not degrade, swell, or corrode when exposed to aggressive acids, caustics, or solvents, ensuring the integrity of the seal over a long service life.

Performance Across a Wide Temperature Range

These gaskets are designed to perform reliably across a wide spectrum of temperatures. They can handle processes with significant heat fluctuations without becoming brittle or losing their sealing capability, a critical factor in many industrial plants.

Ensuring Product Purity

Because PTFE is non-contaminating, odorless, and non-absorbent, it is an ideal choice for sensitive applications. Industries like food and beverage, pharmaceuticals, and electronics rely on these gaskets to prevent any contamination of the final product.

Superior Mechanical Sealing Performance

Beyond its material properties, the design of an envelope gasket provides distinct mechanical advantages that ensure a tight, durable seal.

High Creep Resistance for Long-Term Integrity

Creep is the tendency of a material to deform or flow out of a flange over time under pressure and heat. PTFE envelope gaskets exhibit high creep resistance, meaning they maintain their shape and sealing pressure, minimizing the need for re-torquing bolts and reducing the risk of leaks.

Consistent Pressure Resistance

The design allows the gasket to withstand high internal pressures without breaking. The PTFE "envelope" protects the core material, while the core provides the structural support needed to maintain a seal under load.

Durability and Slow Aging

The robust construction and inherent stability of PTFE mean these gaskets are resistant to aging and embrittlement. This leads to a longer service life, reducing the frequency of replacement and lowering overall maintenance costs.

Key Considerations and Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is critical for proper application.

The Importance of the Insert Material

The performance of an envelope gasket is heavily dependent on its insert material. A soft, compressible insert may seal well on irregular flanges but have a lower temperature limit. A stronger metallic core will handle higher pressures but demands a better flange surface. The choice of insert dictates the gasket's ultimate pressure, temperature, and recovery capabilities.

Flange Condition and Bolt Load

PTFE is a relatively hard material compared to softer elastomers. To achieve an effective seal, it typically requires a clean, smooth flange surface and a higher, more uniform bolt load. Using these gaskets on damaged or warped flanges can easily result in leaks.

Cost vs. Performance

PTFE gaskets generally represent a higher upfront cost compared to standard non-asbestos or elastomeric gaskets. This cost must be weighed against the long-term benefits of reduced maintenance, extended service life, and enhanced operational safety in the specific application.

Making the Right Choice for Your Application

Selecting the correct gasket requires aligning its benefits with your primary operational goal.

- If your primary focus is handling aggressive chemicals: This gasket is an industry-standard choice due to PTFE's unparalleled chemical inertness.

- If your primary focus is ensuring product purity: The non-contaminating properties of PTFE make it an ideal solution for food, beverage, and pharmaceutical processes.

- If your primary focus is long-term reliability in a stable process: The excellent creep resistance and durability offer a low-maintenance, "set it and forget it" sealing solution.

Ultimately, selecting a PTFE envelope gasket is a strategic decision for achieving operational integrity in chemically aggressive and sensitive environments.

Summary Table:

| Benefit | Key Feature | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to acids, caustics, and solvents | Aggressive chemical processes |

| Thermal Stability | Performs across a wide temperature range | Processes with heat fluctuations |

| Product Purity | Non-contaminating and non-absorbent | Food, Pharma, and Semiconductor |

| Mechanical Integrity | High creep resistance and durability | Long-term, low-maintenance sealing |

Need a reliable PTFE gasket solution for your critical process?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom mill-type envelope gaskets. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication—from prototypes to high-volume orders—ensure you get a seal that guarantees purity, safety, and long-term reliability.

Contact our experts today to discuss your specific application requirements and get a custom solution that protects your process.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications