The primary benefits of PTFE guide strips are their ability to eliminate the jerky, uncontrolled "stick-slip" effect in moving parts and to prevent damaging metal-to-metal contact. By doing so, they significantly increase the lifespan and efficiency of dynamic seals, offer high wear resistance, absorb vibration, and provide a long service life under high compressive loads.

The core value of PTFE guide strips is not just in their material properties but in their function as a system-level enhancement. They act as a critical buffer, preserving the integrity and performance of an entire assembly by minimizing the two primary causes of failure: friction and wear.

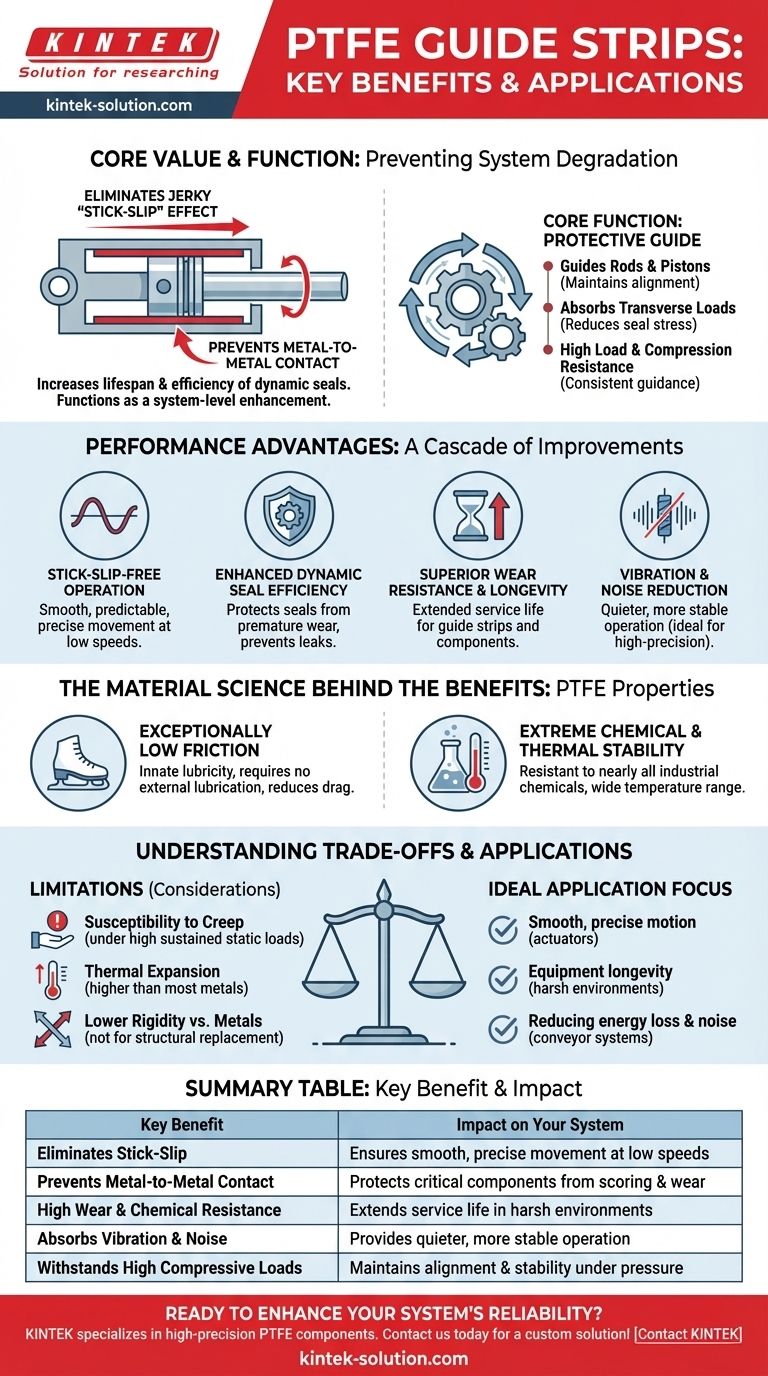

The Core Function: Preventing System Degradation

PTFE guide strips are engineered to solve fundamental mechanical problems. Their primary role is to act as a protective guide for moving components, particularly in demanding hydraulic and pneumatic systems.

Eliminating Metal-to-Metal Contact

The most immediate benefit is the prevention of direct contact between moving metal parts, such as a piston rod and a cylinder bore. This sacrificial layer of PTFE absorbs the wear, protecting more expensive and critical system components from scoring and deterioration.

Guiding Rods and Pistons

In hydraulic and pneumatic applications, these strips guide the rod or piston, maintaining precise alignment. They are designed to absorb transverse (radial) loads, ensuring the primary sealing elements are not subjected to undue stress, which allows the seals to function correctly.

High Load and Compression Resistance

Despite its low-friction surface, PTFE is formulated for high compressive strength. This allows guide strips to withstand significant side loads without being crushed, ensuring consistent guidance and stability throughout the operational cycle.

Unpacking the Performance Advantages

The physical placement of the guide strips leads to a cascade of performance improvements that are felt across the entire system.

Stick-Slip-Free Operation

"Stick-slip" refers to the stuttering motion that occurs at low speeds when static friction is significantly higher than dynamic friction. PTFE's exceptionally low coefficient of friction virtually eliminates this effect, ensuring smooth, predictable, and precise movement.

Enhanced Dynamic Seal Efficiency

By ensuring smooth rod movement and absorbing side loads, guide strips protect the system's primary seals from premature wear. A stable, properly guided rod allows the seal to maintain consistent pressure and prevent leaks far more effectively.

Superior Wear Resistance and Longevity

The inherent properties of PTFE, combined with its role in reducing system friction, result in extremely high wear resistance. This translates directly to a longer service life for both the guide strip and the components it protects, reducing maintenance intervals and costs.

Vibration and Noise Reduction

The material's natural damping characteristics allow it to absorb mechanical vibrations. This leads to quieter, more stable operation, which is a critical factor in high-precision machinery and conveyor systems.

The Material Science Behind the Benefits

The unique advantages of PTFE guide strips are a direct result of the molecular properties of Polytetrafluoroethylene resin.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material. This innate lubricity is why it requires no external lubrication, reduces energy loss due to drag, and is the key to eliminating stick-slip.

Extreme Chemical and Thermal Stability

PTFE is chemically inert, meaning it is resistant to nearly all industrial chemicals, solvents, and corrosive fluids. Coupled with its wide operating temperature range, this makes it an ideal choice for harsh operating environments in the automotive, aerospace, and chemical processing industries.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations.

Susceptibility to Creep

Under high, sustained static loads, PTFE can be subject to "creep," a slow, permanent deformation over time. This must be considered in applications where the guide will be stationary under heavy load for extended periods.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than most metals. In designs with very tight tolerances that operate across a wide temperature range, this difference in expansion and contraction rates must be carefully calculated to avoid binding or failure.

Lower Rigidity vs. Metals

While strong in compression, PTFE is a much softer material than bronze or other metals used for bearings. It should not be used as a direct structural replacement for a metal bearing in applications requiring extreme rigidity.

Making the Right Choice for Your Application

Selecting PTFE guide strips should be based on your system's most critical performance requirement.

- If your primary focus is smooth, precise motion: PTFE's ability to eliminate stick-slip makes it the ideal choice for hydraulic and pneumatic actuators where control is paramount.

- If your primary focus is equipment longevity in harsh environments: Its chemical inertness and thermal stability protect components in aerospace, automotive, and chemical processing applications.

- If your primary focus is reducing energy loss and operational noise: The low-friction properties minimize drag and absorb vibration, making it perfect for conveyor systems and other dynamic machinery.

Ultimately, integrating PTFE guide strips is a strategic decision to enhance the reliability, efficiency, and lifespan of any critical moving system.

Summary Table:

| Key Benefit | Impact on Your System |

|---|---|

| Eliminates Stick-Slip | Ensures smooth, precise movement at low speeds |

| Prevents Metal-to-Metal Contact | Protects critical components from scoring and wear |

| High Wear & Chemical Resistance | Extends service life in harsh environments |

| Absorbs Vibration & Noise | Provides quieter, more stable operation |

| Withstands High Compressive Loads | Maintains alignment and stability under pressure |

Ready to enhance your system's reliability and performance? KINTEK specializes in manufacturing high-precision PTFE components, including custom guide strips, seals, liners, and labware. We serve the semiconductor, medical, laboratory, and industrial sectors, offering solutions from prototypes to high-volume orders. Our expertise ensures your equipment runs smoother, lasts longer, and operates more efficiently. Contact KINTEK today to discuss your specific needs and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of Teflon-encapsulated O-Rings? Superior Sealing for Demanding Industrial Applications

- Why are PTFE gaskets suitable for the food and beverage industry? Ensure Purity, Hygiene & Performance

- What are the electrical properties of PTFE bushes? Superior Insulation for High-Performance Applications

- What machining processes are suitable for Teflon/PTFE? Master Precision Machining for Soft Materials

- What are the benefits of using PTFE in medical implants? Achieve Superior Biocompatibility & Performance

- What factors should be considered when choosing between PTFE and graphite braided packing? Select the Right Seal for Your Application

- What industries benefit from PTFE and PFA lined check valves? Ensure Safety and Purity in Harsh Processes

- What is the purpose of the holes in PTFE lined butterfly valves? Ensure Perfect Alignment for Leak-Proof Sealing