In short, Polytetrafluoroethylene (PTFE) is used in medical implants because of its exceptional biocompatibility, chemical inertness, and extremely low friction. This unique combination of properties ensures that an implant made from PTFE can function reliably inside the human body for long periods without causing adverse reactions or degrading.

The core reason for PTFE's value in medicine is not just one superior feature, but its rare ability to be almost completely ignored by the body's immune system while simultaneously providing the physical durability and performance required of a medical device.

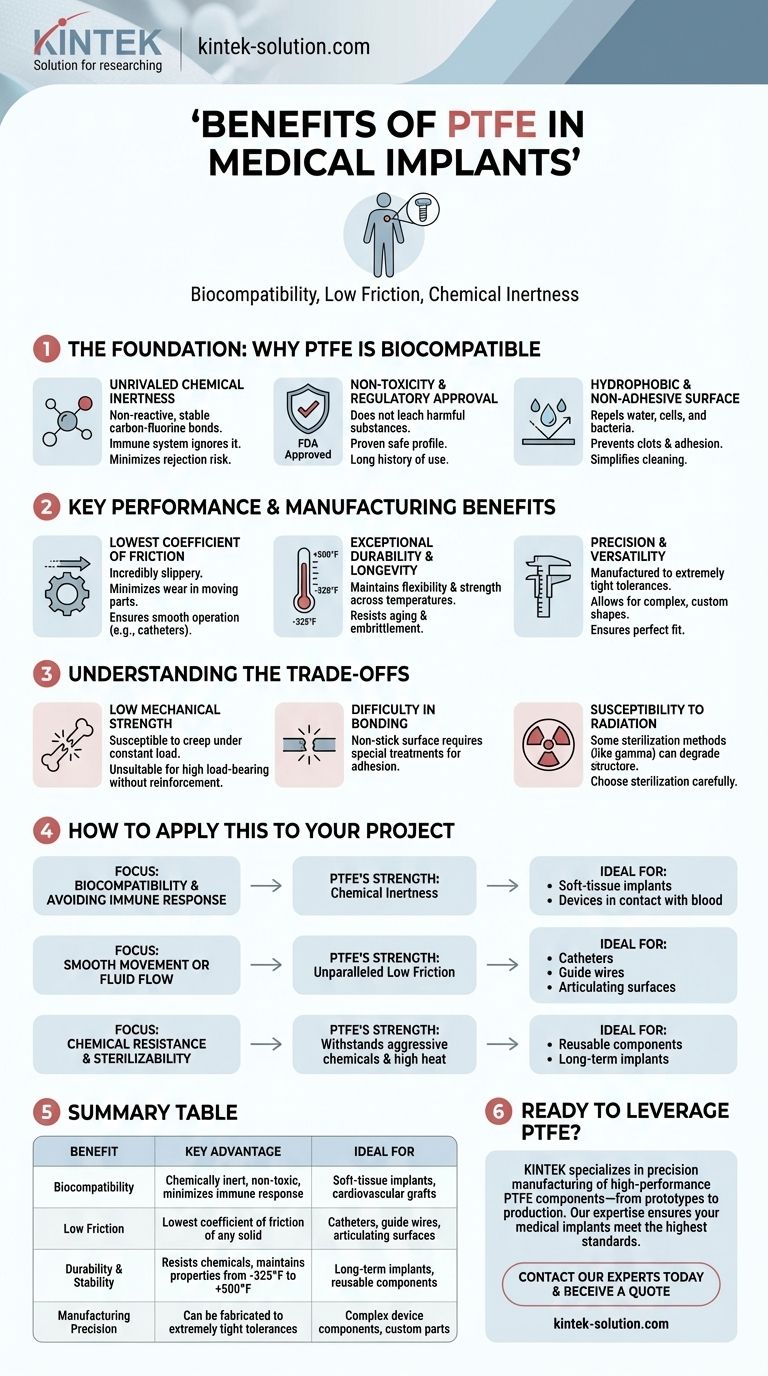

The Foundation: Why PTFE is Biocompatible

The primary requirement for any material placed inside the human body is that it does not cause harm. PTFE excels in this area due to its fundamental chemical structure.

Unrivaled Chemical Inertness

PTFE is one of the most non-reactive substances known. Its strong carbon-fluorine bonds make it resistant to virtually all chemicals and bodily fluids.

This inertness means the body's immune system largely ignores its presence, dramatically reducing the risk of rejection, inflammation, or other negative immune responses.

Non-Toxicity and Regulatory Approval

Because of its stable and inert nature, PTFE is non-toxic. It does not leach harmful substances into the body over time.

This stellar safety profile is why materials made from PTFE have a long history of FDA approval for use in a wide range of medical-grade applications.

Hydrophobic and Non-Adhesive Surface

PTFE is highly hydrophobic, meaning it repels water. This property, combined with its famous non-stick surface, prevents cells, proteins, and bacteria from adhering to the implant.

This is critical for applications like cardiovascular grafts, where preventing blood clots is a primary concern. It also simplifies cleaning and sterilization.

Key Performance and Manufacturing Benefits

Beyond its safety, PTFE provides a suite of physical properties that make it an ideal engineering material for complex medical devices.

The Lowest Coefficient of Friction

PTFE has the lowest coefficient of friction of any known solid material. This makes it incredibly slippery.

For implants involving moving parts or fluid flow, such as catheters or synthetic joint components, this property minimizes wear and tear and ensures smooth operation.

Exceptional Durability and Longevity

PTFE does not suffer from embrittlement or aging in the same way many other plastics do. It maintains its flexibility and strength over a vast temperature range (from -325°F to +500°F).

This ensures the implant remains stable and reliable for the duration of its intended service life inside the body.

High Thermal Stability

The material's ability to withstand continuous working temperatures up to +260°C (+500°F) is a significant advantage.

This allows implants made from PTFE to be sterilized using high-temperature methods like autoclaving without compromising their structural integrity.

Precision and Versatility

PTFE can be manufactured to extremely tight tolerances, allowing for the creation of complex and precise shapes required for advanced medical devices.

This dimensional accuracy ensures that components like orthopedic screws or vascular grafts fit perfectly and function as designed.

Understanding the Trade-offs

No material is perfect. While PTFE's benefits are substantial, it's critical to understand its limitations for proper application.

Relatively Low Mechanical Strength

Compared to metals or other high-performance polymers like PEEK, PTFE has lower tensile strength and is susceptible to "creep" (slow deformation under constant load).

This makes it unsuitable for primary, high-load-bearing applications, such as a total hip joint replacement, without reinforcement.

Difficulty in Bonding

PTFE's non-stick surface makes it very difficult to bond to other materials using conventional adhesives. Special surface treatments like chemical etching are often required to achieve a strong bond.

Susceptibility to Radiation

While resistant to heat, some common sterilization methods like gamma radiation can degrade PTFE's molecular structure, potentially weakening the material. The sterilization method must be chosen carefully.

How to Apply This to Your Project

Your choice of material depends entirely on the primary challenge you are trying to solve with your medical device.

- If your primary focus is biocompatibility and avoiding immune response: PTFE's chemical inertness is its most valuable asset, making it ideal for soft-tissue implants and devices in contact with blood.

- If your primary focus is smooth movement or fluid flow: PTFE's unparalleled low coefficient of friction is the deciding factor for applications like catheters, guide wires, and articulating surfaces.

- If your primary focus is chemical resistance and sterilizability: PTFE's ability to withstand aggressive chemicals and high-temperature sterilization makes it a reliable choice for reusable components and long-term implants.

Ultimately, PTFE's selection for medical implants is a testament to its unique ability to exist harmoniously within the human body while delivering consistent, reliable performance.

Summary Table:

| Benefit | Key Advantage | Ideal For |

|---|---|---|

| Biocompatibility | Chemically inert, non-toxic, minimizes immune response | Soft-tissue implants, cardiovascular grafts |

| Low Friction | Lowest coefficient of friction of any solid | Catheters, guide wires, articulating surfaces |

| Durability & Stability | Resists chemicals, maintains properties from -325°F to +500°F | Long-term implants, reusable components |

| Manufacturing Precision | Can be fabricated to extremely tight tolerances | Complex device components, custom parts |

Ready to leverage the benefits of PTFE for your medical device?

KINTEK specializes in the precision manufacturing of high-performance PTFE components—from custom prototypes to high-volume production. Our expertise ensures your medical implants meet the highest standards for biocompatibility, durability, and performance.

Contact our experts today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the common applications of PTFE pneumatic valves? Ensure Purity and Chemical Resistance in Your Process

- What material are PTFE heat press sheets made from? Unlock Consistent, Professional Results

- What are the key properties of PTFE? Unmatched Chemical, Thermal, and Friction Performance

- How do PTFE coated fasteners perform in marine and offshore environments? Superior Corrosion Protection for Critical Assets

- What are the characteristics of unfilled PTFE sheets made from virgin PTFE resin? Achieve Ultimate Purity and Performance

- What advantages do PTFE expansion bellows offer over traditional alternatives? Achieve Unmatched Reliability in Demanding Environments

- What are the symptoms of a leaking PTFE butterfly valve? Identify External & Internal Leaks

- How do PTFE-lined valves compare to traditional metallic valves? Maximize Performance in Corrosive Applications