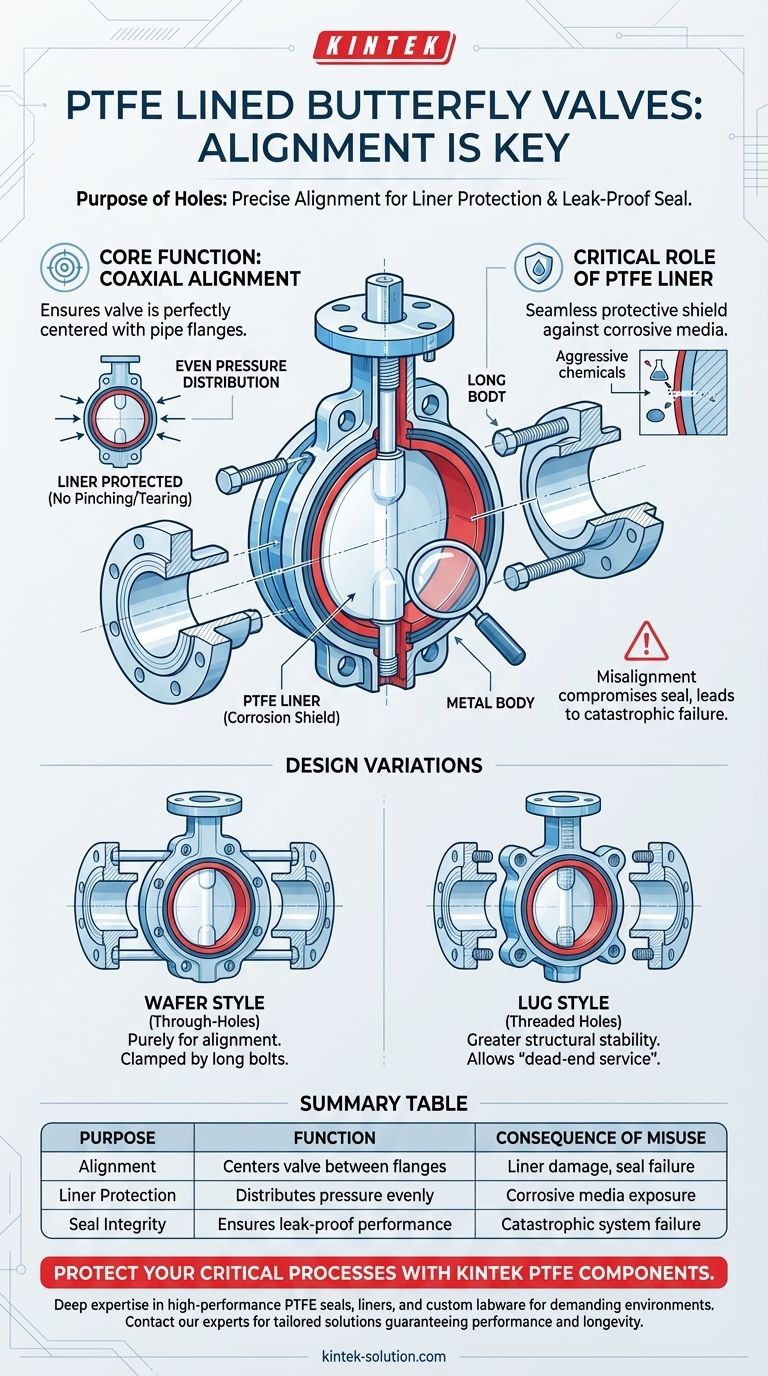

In short, the holes in a PTFE lined butterfly valve are for alignment. These are not for flow; they are locator or "lug" holes designed to perfectly center the valve between two pipe flanges during installation, ensuring a leak-proof seal without damaging the sensitive internal liner.

The core purpose of these alignment holes is to protect the valve's most critical feature: its Polytetrafluoroethylene (PTFE) liner. Proper alignment is non-negotiable, as even a slight offset during installation can compromise the seal, damage the liner, and lead to catastrophic failure in corrosive service.

Deconstructing the Valve's Design

To understand the function of these holes, you must first understand the unique construction of this type of valve. It is designed to be "sandwiched" between two sections of pipe.

The Critical Role of the PTFE Liner

A PTFE lined butterfly valve uses a standard metal body, but its entire internal surface is coated with a seamless layer of PTFE. This liner acts as a protective shield.

Its purpose is to provide exceptional corrosion resistance against aggressive chemicals, acids, or high-purity media that would otherwise destroy the metal valve body. The integrity of this liner is paramount.

The "Sandwich" Installation Method

Unlike valves that have their own integrated flanges, these valves are typically a "wafer" or "lug" style. This means the valve body itself is a compact ring that fits between two existing pipe flanges.

Long bolts are then passed through the flanges and the alignment holes on the valve body, clamping the entire assembly together.

The Function of the Alignment Holes

The holes ensure the valve is perfectly coaxial with the pipe. When the flanges are tightened, this precise alignment guarantees that clamping pressure is distributed evenly across the PTFE sealing faces.

This prevents the liner from being pinched, torn, or deformed, which would create an immediate leak path and expose the metal body to corrosive materials.

The Consequences of Improper Alignment

Failing to use these alignment holes correctly can lead to several severe problems that defeat the entire purpose of specifying a high-performance lined valve.

Compromising the Protective Seal

If the valve is off-center, the flange tightening will create uneven pressure on the PTFE liner. This can easily damage the raised sealing surface of the liner, resulting in a loss of the "zero leakage" performance these valves are known for.

Damaging the Disc and Actuator

A misaligned valve can prevent the internal disc from opening or closing properly. The edge of the disc may strike the inside of the pipe flange, causing physical damage to the disc, the liner, and placing excessive strain on the valve's stem and actuator.

Understanding Design Variations

The alignment holes come in two primary configurations, which define the valve's specific type and application.

Through-Holes (Wafer Style)

Valves with simple through-holes are known as wafer style. They are purely for alignment.

The valve is held in place exclusively by the compressive force of long bolts that span from one pipe flange to the other, passing through the holes in the valve body.

Threaded Holes (Lug Style)

Valves with threaded holes are known as lug style. Short bolts (cap screws) are installed from each flange into the threaded "lugs" of the valve body.

This design provides greater structural stability and allows for "dead-end service," meaning the piping on one side can be removed for maintenance while the valve remains bolted to the other, holding back the pressure.

Making the Right Choice for Your Goal

The presence of these holes is a fundamental design feature linked directly to the valve's function and installation method.

- If your primary focus is corrosion resistance: You must use the alignment holes to ensure the integrity of the PTFE liner, which is the sole barrier against chemical attack.

- If your primary focus is system maintainability: A lug-style valve with threaded holes is the superior choice, as it allows for easier disassembly of downstream piping.

- If your primary focus is installation integrity: Regardless of type, always use the holes to guide the valve into its coaxial position before applying any torque to the flange bolts.

Ultimately, these simple holes are a critical feature that ensures a sophisticated valve can deliver its promised performance and longevity.

Summary Table:

| Purpose | Function | Consequence of Misuse |

|---|---|---|

| Alignment | Centers valve between pipe flanges | Liner damage, seal failure |

| Liner Protection | Distributes clamping pressure evenly | Corrosive media exposure |

| Seal Integrity | Ensures leak-proof performance | Catastrophic system failure |

Protect your critical processes with precision-engineered PTFE components from KINTEK.

Our deep expertise in manufacturing high-performance PTFE seals, liners, and custom labware ensures your equipment operates reliably in the most demanding semiconductor, medical, and industrial environments. We specialize in custom fabrication from prototypes to high-volume orders, delivering the precision and corrosion resistance your application demands.

Contact our experts today to discuss your specific requirements and receive a tailored solution that guarantees performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech