The primary advantage of Teflon-encapsulated O-rings is their unique ability to combine the extreme chemical inertness of a Teflon jacket with the reliable sealing force of an elastomeric core. This hybrid design creates a robust solution for demanding industrial applications where a standard rubber O-ring would quickly degrade and fail.

The fundamental value of a Teflon-encapsulated O-ring is not one single feature, but the fusion of two materials. It uses a resilient elastomeric core for sealing pressure and a durable Teflon jacket for near-universal protection against chemical attack and extreme temperatures.

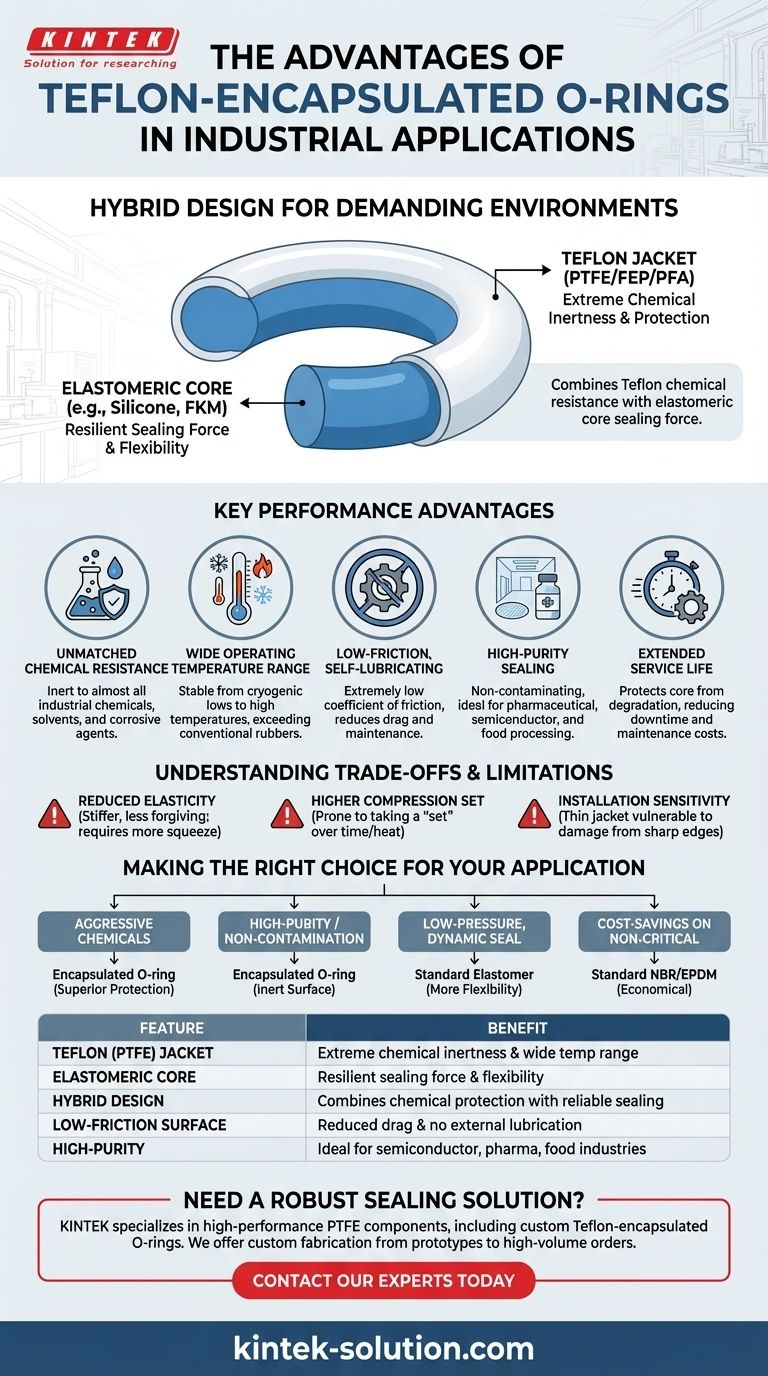

The Hybrid Design: How It Works

To understand the advantages, you must first understand the construction. These seals are not made of a single material but are a composite of two distinct components.

The Inner Core

The core is typically made from a standard elastomer like Silicone or FKM (Viton®). This material provides the flexibility, resilience, and "bounce-back" necessary to create and maintain a tight seal under pressure.

The Outer Jacket

This flexible core is seamlessly enclosed within a thin, protective jacket of Teflon (PTFE/FEP/PFA). This outer layer is what interfaces with the operating environment, shielding the more vulnerable core from harm.

Key Performance Advantages Explained

This dual-material construction delivers a unique combination of benefits that are impossible to achieve with a single material.

Unmatched Chemical Resistance

The Teflon jacket is virtually inert to almost all industrial chemicals, solvents, and corrosive agents. This allows the O-ring to function reliably in aggressive environments that would destroy a standard elastomer.

Wide Operating Temperature Range

Teflon provides exceptional thermal stability, allowing these O-rings to perform in conditions ranging from cryogenic lows to high-temperature applications, far exceeding the range of many conventional rubbers.

Low-Friction, Self-Lubricating Surface

Teflon possesses an extremely low coefficient of friction. This "slippery" surface reduces drag in dynamic applications and eliminates the need for external lubrication, which in turn cuts down on maintenance and potential system contamination.

High-Purity Sealing

Because the Teflon jacket is non-contaminating and resistant to chemical leaching, these O-rings are ideal for high-purity systems. They are widely used in pharmaceutical, semiconductor, and food processing industries.

Extended Service Life

By protecting the elastomeric core from chemical attack and thermal degradation, the Teflon jacket dramatically extends the operational lifespan of the seal. This leads to reduced downtime and lower maintenance costs over time.

Understanding the Trade-offs and Limitations

While powerful, this design is not a universal solution. An objective assessment requires acknowledging its inherent limitations, which stem directly from its construction.

Reduced Elasticity

The Teflon jacket is more rigid than a standard elastomer. This makes the O-ring stiffer and less forgiving. It requires more squeeze (compression) to achieve a proper seal compared to a standard O-ring.

Higher Compression Set

Due to the plastic nature of Teflon, these seals are more prone to taking a "set" after being compressed for long periods, especially at high temperatures. They have less "memory" or rebound capability than a pure high-performance elastomer.

Installation Sensitivity

The thin Teflon jacket can be scratched, nicked, or damaged during installation on sharp-edged hardware. This can compromise the seal's integrity, requiring more careful handling and installation procedures than a standard rubber O-ring.

Making the Right Choice for Your Application

Selecting the correct seal depends entirely on the demands of your specific operating environment.

- If your primary focus is aggressive chemical compatibility: The encapsulated O-ring is the superior choice, providing protection that standard elastomers cannot match.

- If your primary focus is high-purity or non-contamination: The inert Teflon surface is essential for industries like semiconductor manufacturing and pharmaceuticals.

- If your primary focus is a low-pressure, dynamic seal requiring maximum flexibility: A standard, high-performance elastomer like FKM might be a better choice due to the inherent stiffness of the encapsulated design.

- If your primary focus is cost-savings on a non-critical application: A standard NBR or EPDM O-ring will be far more economical where chemical and thermal demands are low.

Understanding this hybrid construction empowers you to select a sealing solution that offers uncompromising performance in your most challenging environments.

Summary Table:

| Feature | Benefit |

|---|---|

| Teflon (PTFE) Jacket | Extreme chemical inertness and wide temperature range |

| Elastomeric Core | Resilient sealing force and flexibility |

| Hybrid Design | Combines chemical protection with reliable sealing |

| Low-Friction Surface | Reduced drag and no need for external lubrication |

| High-Purity | Ideal for semiconductor, pharmaceutical, and food processing industries |

Need a robust sealing solution for a challenging environment?

KINTEK specializes in manufacturing high-performance PTFE components, including custom Teflon-encapsulated O-rings. Our seals are designed to provide uncompromising chemical resistance and longevity in the most demanding semiconductor, medical, laboratory, and industrial applications.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get the precise seal your operation requires.

Contact our experts today to discuss your specific needs and get a solution that delivers superior performance and reliability.

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industrial applications does PTFE have? Unlock Performance in Extreme Environments

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What material is the PTFE bottle made from? Discover the Benefits of 100% Virgin PTFE

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss