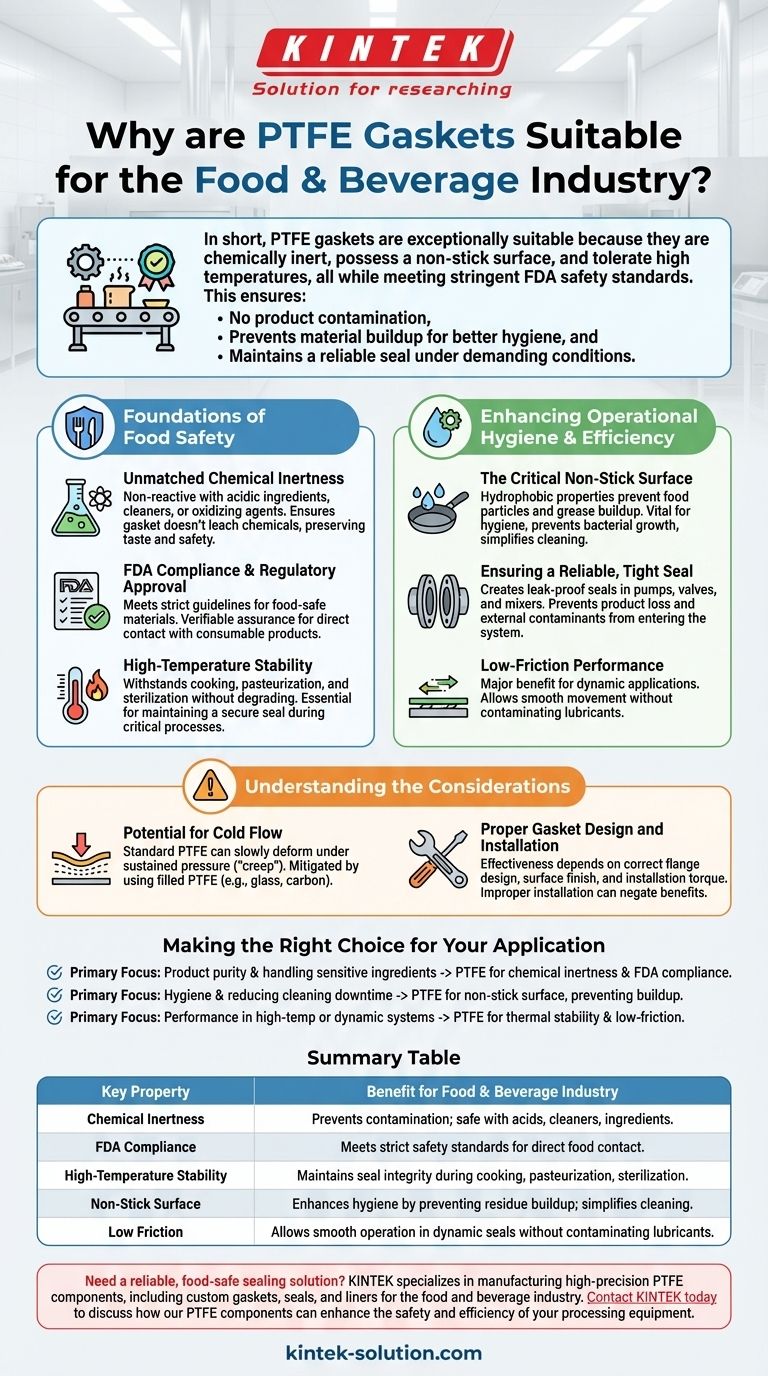

In short, PTFE gaskets are exceptionally suitable for the food and beverage industry because they are chemically inert, possess a non-stick surface, and tolerate high temperatures, all while meeting stringent FDA safety standards. This unique combination ensures that the gasket will not contaminate food products, prevents material buildup for better hygiene, and maintains a reliable seal under demanding processing conditions.

The core reason for PTFE's widespread use in food applications is its ability to create a pure, safe, and stable barrier. It protects the integrity of the food or beverage by not reacting with it, not sticking to it, and not breaking down under the heat and chemicals used in modern processing.

The Foundations of Food Safety with PTFE

To understand why PTFE is a trusted material, we must first look at its fundamental properties that directly address the primary concern of the food industry: product safety and purity.

Unmatched Chemical Inertness

PTFE is one ofthe most non-reactive materials known. It does not react with acidic ingredients, cleaning agents, or oxidizing agents commonly found in food and beverage processing.

This inertness is critical because it ensures the gasket itself does not leach chemicals into the product, preserving its intended taste, color, and safety.

FDA Compliance and Regulatory Approval

Materials used in food processing equipment are not chosen arbitrarily. They must meet strict regulatory guidelines to be considered food-safe.

PTFE grades intended for these applications comply with FDA standards. This certification provides a verifiable assurance that the material is safe for direct contact with consumable products.

High-Temperature Stability

Food and beverage processing often involves high temperatures for cooking, pasteurization, or sterilization.

PTFE gaskets can withstand consistent use at high temperatures without degrading or losing their sealing capability. This thermal stability is essential for maintaining a secure seal and preventing equipment failure during critical processes.

Enhancing Operational Hygiene and Efficiency

Beyond safety, PTFE provides significant operational advantages that contribute to a cleaner, more efficient processing environment.

The Critical Non-Stick Surface

PTFE is renowned for its non-stick, or hydrophobic, properties. In a processing environment, this means that food particles, grease, and other residues do not adhere to the gasket surface.

This quality is vital for hygiene, as it prevents the buildup of deposits that could harbor bacteria. It also dramatically simplifies cleaning procedures, reducing downtime and ensuring sanitary conditions are easily maintained.

Ensuring a Reliable, Tight Seal

PTFE gaskets are used to create tight, leak-proof seals in essential equipment like pumps, valves, mixers, and heat exchangers.

Preventing leaks is not only about preventing product loss but also about stopping external contaminants from entering the system. A reliable seal is a cornerstone of a controlled and safe processing line.

Low-Friction Performance

In dynamic applications like rotary shaft seals or non-metal bearings, PTFE's low coefficient of friction is a major benefit.

It allows parts to move smoothly without requiring lubricants like grease, which could otherwise become a source of product contamination.

Understanding the Considerations

While PTFE is an excellent material, no solution is universal. A proper technical assessment involves understanding the context of its application.

Potential for Cold Flow

Standard PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms under sustained pressure, potentially compromising the seal over time.

This is often mitigated by using filled PTFE variants, which incorporate materials like glass, carbon, or stainless steel to enhance rigidity and resistance to creep.

Proper Gasket Design and Installation

The effectiveness of any gasket, including PTFE, is highly dependent on correct flange design, surface finish, and proper installation torque.

An improperly installed PTFE gasket can fail to seal effectively, negating its material benefits. It's crucial that engineering and maintenance teams follow best practices for installation.

Making the Right Choice for Your Application

Selecting the right gasket material depends on the specific demands of your process.

- If your primary focus is product purity and handling sensitive ingredients: PTFE's chemical inertness and FDA compliance make it the safest choice to prevent any interaction or contamination.

- If your primary focus is hygiene and reducing cleaning downtime: The non-stick surface of PTFE is your greatest asset, as it prevents material buildup and simplifies sanitation protocols.

- If your primary focus is performance in high-temperature or dynamic systems: The thermal stability and low-friction nature of PTFE ensure reliable sealing and movement without the need for potentially contaminating lubricants.

Ultimately, PTFE's unique combination of safety, hygiene, and performance makes it a foundational material for reliable food and beverage processing.

Summary Table:

| Key Property | Benefit for Food & Beverage Industry |

|---|---|

| Chemical Inertness | Prevents contamination; safe with acids, cleaners, and ingredients. |

| FDA Compliance | Meets strict safety standards for direct food contact. |

| High-Temperature Stability | Maintains seal integrity during cooking, pasteurization, and sterilization. |

| Non-Stick Surface | Enhances hygiene by preventing residue buildup; simplifies cleaning. |

| Low Friction | Allows smooth operation in dynamic seals without contaminating lubricants. |

Need a reliable, food-safe sealing solution?

KINTEK specializes in manufacturing high-precision PTFE components, including custom gaskets, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors, with expertise in meeting the stringent purity and performance demands of the food and beverage industry.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to ensure a perfect fit for your application.

Contact KINTEK today to discuss how our PTFE components can enhance the safety and efficiency of your processing equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency