The primary advantages of PTFE sheet lining are its exceptional chemical resistance and its suitability for protecting large chemical tanks from corrosion. This method creates a durable, non-reactive barrier that is particularly effective against aggressive acids and other corrosive substances, ensuring the structural integrity of the tank and the purity of its contents.

While PTFE sheet lining offers arguably the best chemical protection available, its success is not automatic. The method's effectiveness is critically dependent on proper tank design, fabrication by specialized installers, and a clear understanding of its limitations, particularly regarding vacuum pressure and tank size.

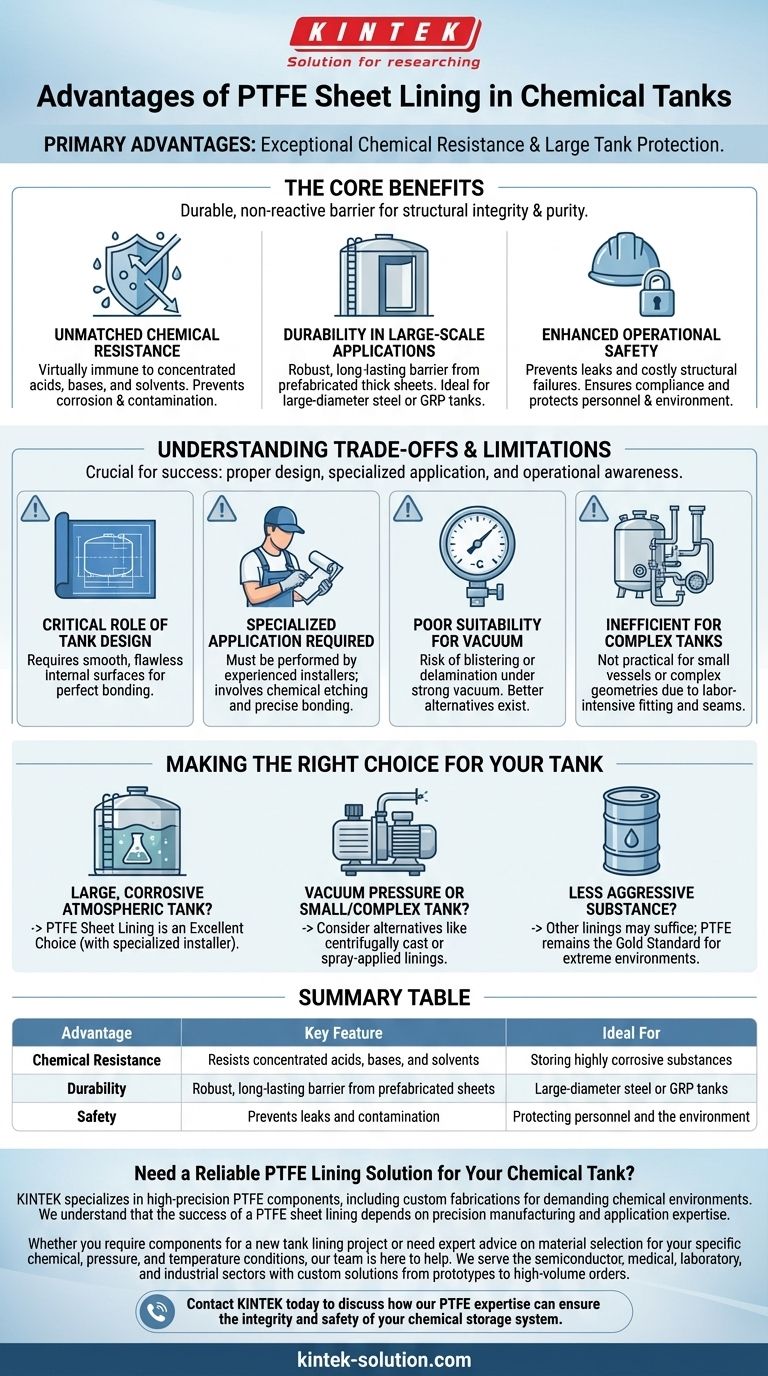

The Core Benefits of PTFE Sheet Lining

Unmatched Chemical Resistance

Polytetrafluoroethylene (PTFE) is one of the most chemically inert materials used in industry. It is virtually immune to attack from a wide range of chemicals, including highly concentrated acids, bases, and solvents.

This superior resistance prevents corrosion of the tank's metal substrate, which eliminates the risk of leaks and costly structural failures. It also prevents contamination of the stored chemical, which is critical for high-purity applications.

Durability in Large-Scale Applications

PTFE sheet lining is an ideal solution for lining large-diameter steel or GRP (Glass Reinforced Plastic) tanks. The process involves adhering thick, prefabricated sheets of PTFE to the tank's interior surface.

This construction method results in a robust and long-lasting protective barrier. When installed correctly, it provides reliable, long-term performance in demanding industrial environments, justifying the initial investment.

Enhanced Operational Safety

By preventing corrosion-related leaks, PTFE sheet lining significantly enhances the safety of a chemical storage facility. Containing highly corrosive or hazardous materials is the primary function of a tank, and a reliable lining is the first line of defense.

The integrity provided by a properly installed PTFE lining ensures compliance with safety regulations and protects personnel and the environment from dangerous spills.

Understanding the Trade-offs and Limitations

The Critical Role of Tank Design

A successful PTFE sheet lining project begins long before the lining is applied. The tank itself must be designed and fabricated with the lining in mind.

The interior surfaces must be smooth, and welds must be ground flush to ensure the adhesive can form a complete and permanent bond. Any imperfections in the tank wall can create stress points or voids, leading to premature lining failure.

Requirement for Specialized Application

Applying a PTFE sheet lining is a highly specialized task that cannot be performed by general contractors. The back of the PTFE sheet must be chemically etched to accept the adhesive, and the application requires a deep understanding of surface preparation and bonding techniques.

This work is performed by specialized companies with proven experience. Attempting this without the right expertise will almost certainly result in a failed lining.

Poor Suitability for Vacuum Conditions

PTFE sheet linings have limited resistance to vacuum pressure. A strong vacuum can pull the sheet away from the tank wall, causing blistering or complete delamination.

If your process involves negative pressure, alternatives such as centrifugally cast or spray-applied linings offer significantly better vacuum resistance and should be your primary consideration.

Inefficiency for Small or Complex Tanks

While excellent for large, simple tanks, the sheet lining method is not practical or cost-effective for small vessels or tanks with complex internal geometries, like multiple nozzles or agitator baffles.

Cutting and fitting sheets around these complexities is labor-intensive and creates numerous seams, which can be potential points of failure. Spray-applied linings are far better suited for such applications.

Making the Right Choice for Your Tank

Choosing a tank lining requires a clear-eyed assessment of your specific operational needs against the distinct capabilities of each technology.

- If your primary focus is containing highly corrosive chemicals in a large atmospheric tank: PTFE sheet lining is an excellent choice, provided you engage a specialized installer and ensure the tank is built to the correct specifications.

- If your application involves vacuum pressure or a small, complex tank: You should strongly consider alternatives like centrifugally cast or spray-applied linings, which are better suited for these conditions.

- If your goal is to protect against a less aggressive substance: A different, less expensive lining material may be sufficient, but PTFE remains the gold standard for extreme chemical environments.

By matching the lining technology to the application's demands, you can ensure the long-term safety, integrity, and efficiency of your chemical processing operation.

Summary Table:

| Advantage | Key Feature | Ideal For |

|---|---|---|

| Chemical Resistance | Resists concentrated acids, bases, and solvents | Storing highly corrosive substances |

| Durability | Robust, long-lasting barrier from prefabricated sheets | Large-diameter steel or GRP tanks |

| Safety | Prevents leaks and contamination | Protecting personnel and the environment |

Need a Reliable PTFE Lining Solution for Your Chemical Tank?

KINTEK specializes in manufacturing high-precision PTFE components, including custom fabrications for demanding chemical environments. We understand that the success of a PTFE sheet lining depends on precision manufacturing and application expertise.

Whether you require components for a new tank lining project or need expert advice on material selection for your specific chemical, pressure, and temperature conditions, our team is here to help. We serve the semiconductor, medical, laboratory, and industrial sectors with custom solutions from prototypes to high-volume orders.

Contact KINTEK today to discuss how our PTFE expertise can ensure the integrity and safety of your chemical storage system.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What industries commonly use CNC machined Teflon parts? Key Sectors Relying on PTFE's Performance

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the advantages of using PTFE-lined expansion joints? Achieve Superior Corrosion and Temperature Resistance

- What long-term business benefits can PTFE diaphragm valves provide to pharmaceutical companies? Boost Yield & Cut Costs

- What are the key roles of PTFE rotary shaft seals in industrial applications? Ensure Reliability in Extreme Conditions

- How should temperature-related seal performance issues be troubleshooted? A Step-by-Step Guide to Thermal Failure

- What are the key steps in the manufacturing process of PTFE coated fasteners? Build a Durable, Corrosion-Resistant Shield

- What machining processes are used to create Teflon parts? Achieve Precision with Expert PTFE Machining