Machining Teflon (PTFE) parts is accomplished using a range of conventional CNC processes, most commonly turning, milling, and drilling. These methods are adapted to accommodate Teflon's unique properties, such as its softness and high rate of thermal expansion, to produce precise components like seals, gaskets, and insulators.

While standard equipment is used, successfully machining Teflon is less about the process and more about the technique. The core challenge is managing the material's softness and extreme sensitivity to heat to prevent deformation and maintain tight tolerances.

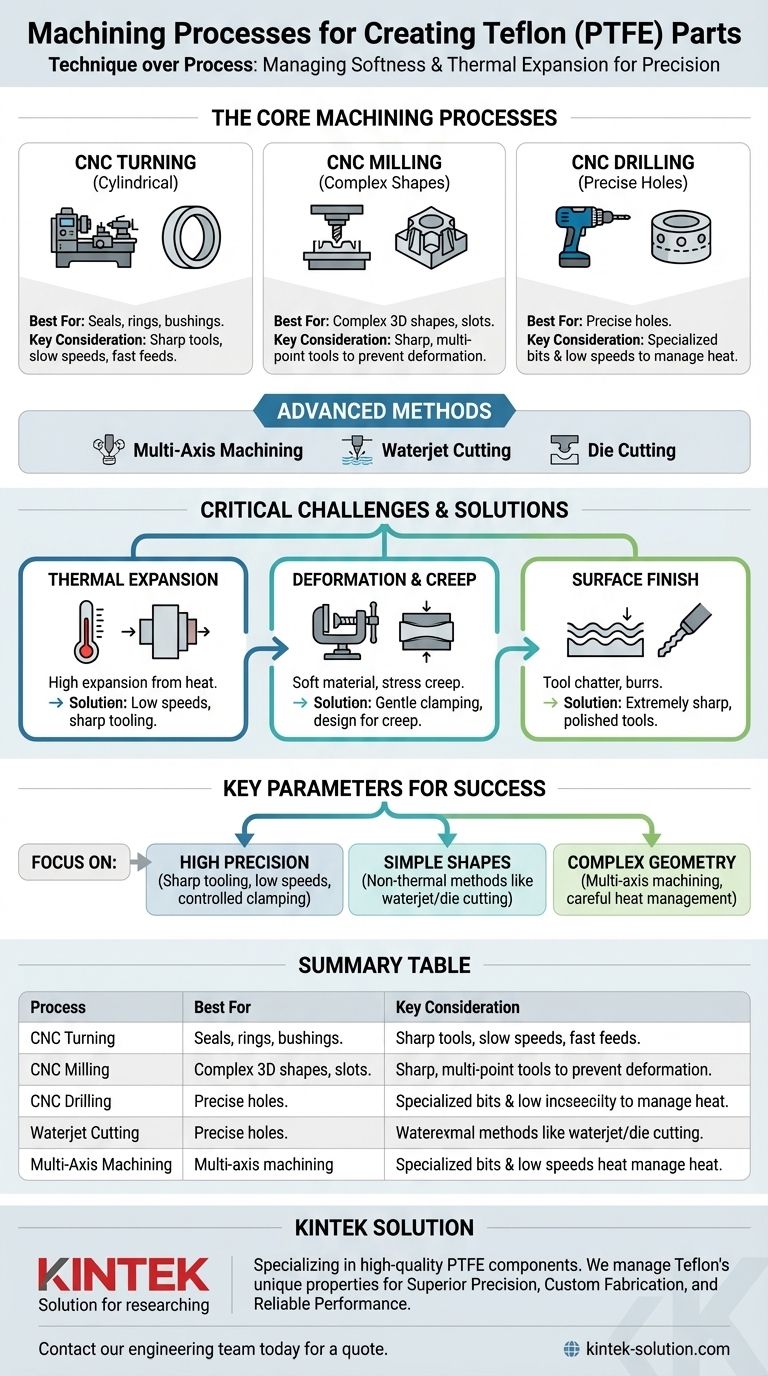

The Core Machining Processes for Teflon

Teflon's versatility allows it to be shaped by several methods, but a few core CNC processes are responsible for the vast majority of custom parts.

CNC Turning for Cylindrical Parts

CNC turning is ideal for creating cylindrical or hollow components. A lathe rotates the Teflon workpiece while a cutting tool removes material.

This process is frequently used for parts like seals, rings, and bushings. Success requires very sharp tools, slow rotational speeds, and relatively fast feed rates to produce a clean cut without melting the material.

CNC Milling for Complex Shapes

CNC milling uses a rotating multi-point cutting tool to remove material from a stationary workpiece. It is the primary method for creating complex geometries, slots, and flat surfaces.

Because of its high precision, milling is essential for parts with intricate designs. As with turning, sharp tools are critical to shear the material cleanly rather than pushing it, which can cause deformation.

CNC Drilling for Precise Holes

Drilling creates holes in Teflon components. However, the friction from a standard drill bit can quickly generate enough heat to melt the material and ruin the part.

Specialized drills, such as those with parabolic flutes, are often used to clear chips effectively. Low cutting speeds are mandatory to prevent heat buildup and ensure the hole's dimensions remain accurate.

Advanced and Specialized Methods

For more specific applications, other processes are employed:

- Multi-Axis/5-Axis Machining: Combines milling and turning for highly intricate parts with complex curves and angles in a single setup.

- Waterjet Cutting: Uses a high-pressure stream of water to cut thick Teflon plates without generating heat.

- Die Cutting: A fast and economical method for stamping simple shapes, like gaskets, from thin Teflon sheets.

Critical Challenges in Machining Teflon

Teflon is not machined like metal or even other plastics. Its distinct properties present unique challenges that must be addressed to achieve a successful outcome.

Managing Thermal Expansion

Teflon has one of the highest coefficients of thermal expansion among polymers. Even a small amount of heat generated from tool friction will cause the part to expand significantly.

This makes maintaining tight tolerances extremely difficult. If not controlled, a part measured as accurate while warm will be out of spec once it cools. This is why low speeds and sharp tooling are non-negotiable.

Preventing Deformation and Creep

Teflon is exceptionally soft and can be easily compressed or deformed. Over-tightening a vise or clamp during setup will crush the material and ruin the final dimensions.

Furthermore, Teflon is prone to stress creep, meaning it can slowly deform over time if left under constant pressure. This must be accounted for in both the workholding strategy and the design of the final part.

Achieving a Clean Surface Finish

The material's softness can lead to tool chatter—a vibration that results in a poor, wavy surface finish. Using extremely sharp, polished cutting tools with the correct geometry is vital to slice through the material cleanly.

An improper cut doesn't create a chip; it creates a burr. These burrs are difficult to remove cleanly and can compromise the function of parts like seals.

Key Parameters for Success

To navigate these challenges, your approach should be dictated by the specific requirements of your component.

- If your primary focus is high-precision tolerances: Prioritize sharp tooling, very low cutting speeds, and controlled clamping pressure to minimize all sources of heat and deformation.

- If your primary focus is producing simple shapes from sheets: Consider non-thermal methods like die cutting or waterjet cutting for maximum efficiency and cost-effectiveness.

- If your primary focus is complex 3D geometry: A multi-axis CNC machine is necessary, but all principles of heat management and gentle workholding still apply.

Mastering these principles allows you to transform Teflon's challenging properties into precisely manufactured, high-performance components.

Summary Table:

| Process | Best For | Key Consideration |

|---|---|---|

| CNC Turning | Cylindrical parts (seals, rings, bushings) | Sharp tools, slow speeds, fast feed rates |

| CNC Milling | Complex 3D shapes and slots | Sharp, multi-point tools to prevent deformation |

| CNC Drilling | Precise holes | Specialized drill bits and low speeds to manage heat |

| Waterjet Cutting | Thick plates, no heat-affected zones | Ideal for simple 2D shapes from sheet stock |

| Multi-Axis Machining | Highly intricate parts with complex curves | Combines operations in a single setup |

Need Precision-Machined Teflon Components?

KINTEK specializes in manufacturing high-quality PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We understand the critical challenges of machining Teflon—like managing thermal expansion and preventing deformation—to deliver parts that meet your tightest tolerances.

Our expertise ensures you get:

- Superior Precision: We use optimized techniques and sharp tooling to manage Teflon's softness and thermal properties.

- Custom Fabrication: From prototypes to high-volume orders, we tailor our approach to your specific part requirements, whether for seals, liners, or complex labware.

- Reliable Performance: We manufacture components that perform consistently in your most demanding applications.

Let's discuss your project requirements. Contact our engineering team today for a quote and see how we can bring precision to your PTFE parts.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments