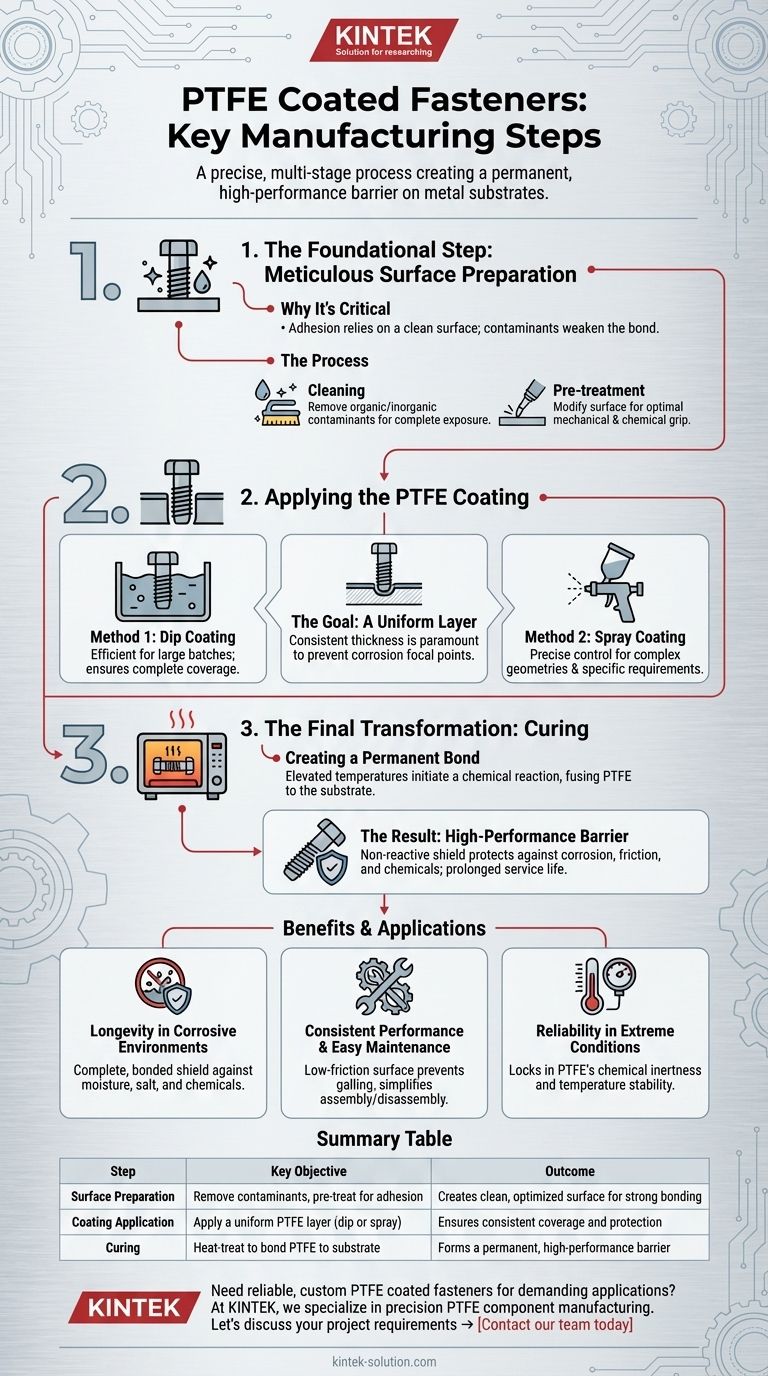

The manufacturing process for PTFE coated fasteners is a precise, multi-stage procedure designed to create a permanent, high-performance barrier on the metal substrate. The core of this process involves three distinct steps: comprehensive surface preparation, uniform coating application, and a high-temperature curing phase that bonds the coating to the fastener.

The goal of the PTFE coating process is not merely to cover the fastener; it is to create a chemically bonded, non-reactive shield. This meticulous process is what gives the final product its exceptional resistance to corrosion, friction, and chemical attack.

The Foundational Step: Meticulous Surface Preparation

The final performance of a PTFE coated fastener is dictated by the quality of its preparation. An improperly prepared surface will compromise the bond, leading to premature failure of the coating.

Why Preparation is Critical

The PTFE coating's adhesion is only as strong as the surface it is bonded to. Any contaminants like oils, dirt, or existing oxides will create a weak point, preventing a proper molecular bond from forming.

The Cleaning Process

The first action is a thorough cleaning to remove all organic and inorganic surface contaminants. This ensures the underlying metal is completely exposed and ready for the next stage.

Pre-treatment for Adhesion

After cleaning, a pre-treatment is applied. This step modifies the fastener's surface to create an optimal profile for the PTFE coating to mechanically and chemically grip onto, ensuring a robust and durable bond.

Applying the PTFE Coating

With the fastener fully prepared, the Polytetrafluoroethylene (PTFE) coating is applied. The primary objective here is to achieve a completely uniform and consistent layer across the entire surface, including threads and crevices.

The Goal: A Uniform Layer

Consistency is paramount. An even coating thickness ensures that there are no thin spots or gaps that could become focal points for corrosion or wear.

Method 1: Dip Coating

In dip coating, fasteners are fully submerged in a liquid PTFE solution. This method is efficient for processing large batches of fasteners at once, ensuring complete coverage.

Method 2: Spray Coating

Spray coating involves applying the PTFE solution using specialized spray guns. This technique offers precise control over the coating thickness and is ideal for complex geometries or specific performance requirements.

The Final Transformation: Curing

The curing stage is arguably the most critical step in the process. It is a controlled heating process that transforms the applied liquid coating into the hard, durable, and bonded solid layer that provides the desired properties.

Creating a Permanent Bond

Curing at elevated temperatures initiates a chemical reaction that permanently bonds the PTFE coating to the pre-treated metal substrate. This is not simply drying; it is a fundamental transformation that fuses the two materials together.

The Result: A High-Performance Barrier

A successfully cured coating provides the exceptional performance PTFE is known for. The non-reactive nature of the now-bonded PTFE shields the underlying metal from corrosive agents like moisture, chemicals, and salts. This process ensures a prolonged service life even in the most demanding environments.

How to Apply This to Your Project

Understanding this process helps you identify when these specialized fasteners are the right choice for your application.

- If your primary focus is longevity in corrosive environments: The multi-stage process ensures a complete, bonded shield against moisture, salt, and industrial chemicals.

- If your primary focus is consistent performance and easy maintenance: The low-friction surface created by the cured PTFE prevents galling and simplifies both assembly and disassembly.

- If your primary focus is reliability in extreme conditions: The entire manufacturing process is designed to lock in PTFE's inherent chemical inertness and temperature stability for predictable performance.

By understanding how these fasteners are made, you can confidently specify them for applications where standard components would fail.

Summary Table:

| Step | Key Objective | Outcome |

|---|---|---|

| Surface Preparation | Remove contaminants and pre-treat for adhesion | Creates a clean, optimized surface for strong bonding |

| Coating Application | Apply a uniform PTFE layer (dip or spray) | Ensures consistent coverage and protection |

| Curing | Heat-treat to bond PTFE to the substrate | Forms a permanent, high-performance barrier |

Need reliable, custom PTFE coated fasteners for demanding applications?

At KINTEK, we specialize in precision PTFE component manufacturing for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get fasteners that deliver superior corrosion resistance, reduced friction, and long-term durability.

Let’s discuss your project requirements → Contact our team today

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F