At its core, a PTFE-lined expansion joint elevates a standard rubber or metal joint by adding a chemically inert, non-stick, and high-temperature-resistant inner layer. This design creates a dual-barrier system where the PTFE liner handles direct contact with aggressive media, while the outer rubber or metal body provides the necessary structural flexibility and pressure containment.

Choosing a PTFE-lined expansion joint is a strategic decision to isolate a corrosive, high-purity, or high-temperature process fluid from the joint's structural body. It combines the extreme resilience of PTFE with the proven mechanical strength of rubber or metal.

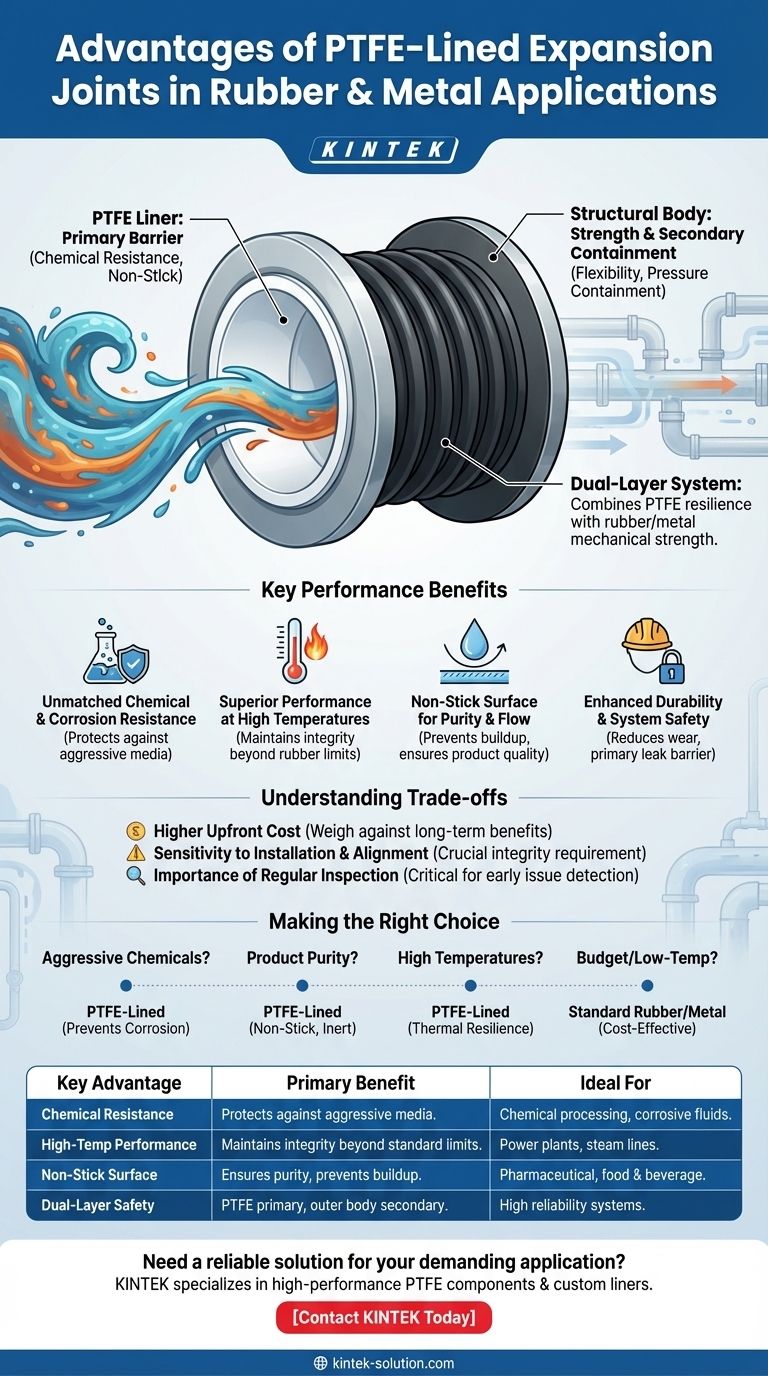

The Fundamental Advantage: A Dual-Layer System

The primary value of a PTFE-lined joint comes from its composite construction. Each layer serves a distinct and critical purpose.

The PTFE Liner: Your Primary Barrier

The Polytetrafluoroethylene (PTFE) liner is the component in direct contact with the process fluid. It acts as a seamless, protective shield.

This liner is responsible for providing the exceptional chemical resistance and non-stick properties that define the joint's performance in demanding applications.

The Structural Body: Strength and Secondary Containment

The outer casing, made of rubber (like EPDM or Neoprene) or metal (like stainless steel), provides the mechanical strength. It absorbs pipe movement, vibration, and thermal expansion.

Crucially, this body also acts as a secondary containment barrier, offering an additional layer of safety should the primary PTFE liner ever be compromised.

Key Performance Benefits of PTFE Lining

By integrating a PTFE liner, an expansion joint gains several capabilities that are impossible to achieve with a single material alone.

Unmatched Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it the ideal barrier for highly corrosive materials found in chemical processing plants.

In metal expansion joints, the liner prevents aggressive fluids from reaching and corroding the thin metal bellows, dramatically extending the joint's service life.

Superior Performance at High Temperatures

While standard rubber joints can degrade in high-temperature service, PTFE maintains its integrity.

This makes PTFE-lined joints essential in applications like power plants, where they must withstand high-pressure steam and significant temperature fluctuations.

Non-Stick Surface for Purity and Flow

PTFE has an extremely low coefficient of friction, creating a "non-stick" surface. This prevents media from adhering to the joint walls.

This characteristic is vital in pharmaceutical and food & beverage industries, where it ensures product purity, prevents contamination, and maintains consistent flow without buildup.

Enhanced Durability and System Safety

The low-friction nature of PTFE reduces wear and potential for damage over time.

By providing a robust primary barrier against hazardous chemicals, the design inherently makes the entire piping system safer and reduces the risk of dangerous leaks or spills.

Understanding the Trade-offs and Considerations

While powerful, PTFE-lined joints are a specialized solution. Objectively weighing their trade-offs is crucial for proper selection.

Higher Upfront Cost

The advanced materials and manufacturing process make PTFE-lined joints more expensive than their standard rubber or unlined metal counterparts. This cost must be weighed against the long-term benefits of increased lifespan and reduced maintenance in a given application.

Sensitivity to Installation and Alignment

The effectiveness of the PTFE liner depends on its integrity. Improper pipe alignment can create stress points, and careless installation can scratch or damage the liner.

Following manufacturer guidelines precisely is not a recommendation; it is a requirement to ensure the joint functions as designed.

The Importance of Regular Inspection

While durable, these joints are not infallible. Regular visual inspections for any signs of wear, delamination, or damage are critical, especially in high-pressure or highly corrosive systems. Early detection of a potential issue prevents catastrophic failure.

Making the Right Choice for Your System

Selecting the correct expansion joint requires matching the technology to your primary operational goal.

- If your primary focus is handling aggressive chemicals: A PTFE-lined joint is essential to prevent corrosion and ensure the long-term integrity of your piping system.

- If your primary focus is product purity or hygiene: The non-stick, inert surface of PTFE is the ideal choice to prevent contamination and ensure process quality.

- If your primary focus is managing high temperatures beyond rubber's limits: A PTFE-lined joint provides the necessary thermal resilience combined with flexibility.

- If your primary focus is budget on a non-corrosive, low-temp system: A standard rubber or unlined metal expansion joint is likely the more cost-effective and appropriate solution.

Ultimately, a PTFE-lined expansion joint is a specialized component that provides unparalleled protection in demanding environments, justifying its selection when system reliability cannot be compromised.

Summary Table:

| Key Advantage | Primary Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Protects against aggressive media, extending joint life. | Chemical processing, corrosive fluids. |

| High-Temperature Performance | Maintains integrity beyond standard rubber limits. | Power plants, steam lines, high-heat processes. |

| Non-Stick Surface | Ensures product purity and prevents media buildup. | Pharmaceutical, food & beverage, high-purity applications. |

| Dual-Layer Safety | PTFE liner for primary containment; outer body for strength. | Systems requiring high reliability and leak prevention. |

Need a reliable solution for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom PTFE liners for expansion joints. We serve the semiconductor, medical, laboratory, and industrial sectors, ensuring precision and durability in every part.

Whether you need a prototype or a high-volume order, our expertise in custom PTFE fabrication can provide the chemical resistance, temperature resilience, and non-stick properties your system requires.

Contact KINTEK today to discuss your specific needs and discover how our PTFE solutions can enhance your system's performance and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors should be considered when determining if PTFE bellows are the best material? Select the Right Material for Your System

- What is a potential downside of PTFE bushings under heavy loads? Prevent Deformation with the Right Material

- What factors should be considered when selecting a PTFE lip seal? Optimize Your Sealing System for Reliability

- How should the right PTFE washer thickness be selected? Balance Sealing, Creep, and Pressure

- How do PTFE O-Rings perform under high heat conditions? Achieve Extreme Temperature Sealing

- How can the lifespan and performance of PTFE bars be maintained? A Guide to Proactive Care

- What material properties make polymer-plastic ball bearings suitable for diverse industries? Solve Harsh Environment Challenges

- What are some tips for successful Teflon machining? Master Precision Cuts for PTFE Components