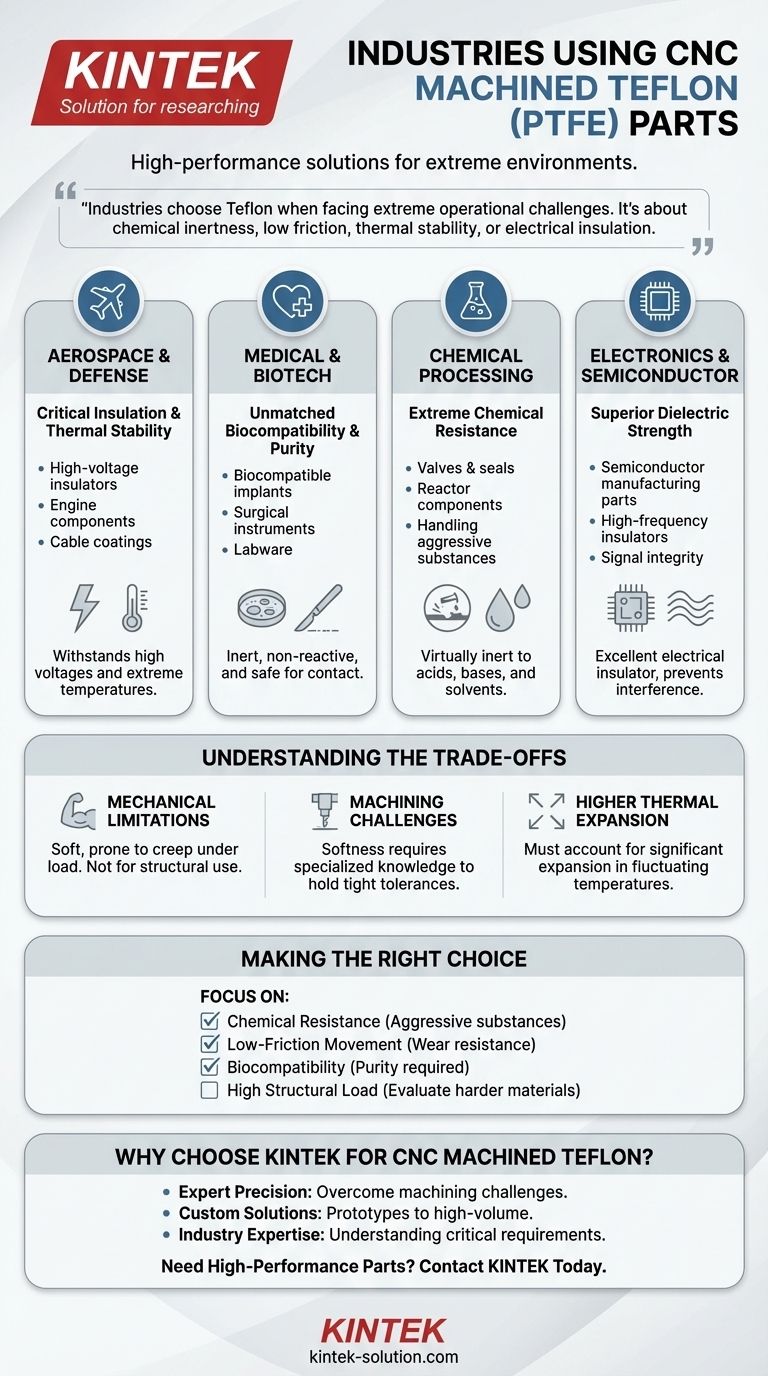

CNC machined Teflon (PTFE) parts are essential components in a wide range of high-performance industries. The most common adopters are the aerospace, medical, chemical processing, and electronics sectors, all of which rely on Teflon's unique combination of properties to function in environments where other materials would fail.

Industries don't choose Teflon by default; they choose it when facing extreme operational challenges. The decision to use CNC machined Teflon almost always comes down to a non-negotiable requirement for chemical inertness, low friction, thermal stability, or electrical insulation.

Why Demanding Sectors Rely on Teflon

Teflon, or Polytetrafluoroethylene (PTFE), isn't a general-purpose plastic. Its value comes from a specific set of high-performance characteristics. Understanding these properties explains exactly which industries use it and why.

For Unmatched Chemical and Biological Inertness

The most defining feature of Teflon is its extreme resistance to chemical attack. It is virtually inert and does not react with most acids, bases, or solvents.

This property makes it indispensable in the medical, chemical processing, and food manufacturing industries. In these fields, preventing contamination and material degradation is paramount.

Applications include biocompatible implants, surgical instruments, valves for handling aggressive chemicals, and non-reactive machinery components for food processing.

For Superior Electrical Insulation

Teflon is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down.

This makes it a critical material in the aerospace and electronics industries. It is used for high-frequency insulators, cable coatings, and components in semiconductor manufacturing equipment.

In these applications, reliable electrical insulation prevents signal interference and short circuits in mission-critical systems.

For Low-Friction Mechanical Performance

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" allows parts to move smoothly against each other without lubrication.

The automotive and general industrial sectors use this property for components like self-lubricating bearings, bushings, seals, and gears. These parts reduce mechanical wear, improve efficiency, and lower maintenance requirements.

For Stability in Extreme Temperatures

Teflon maintains its properties across a wide range of temperatures, from cryogenic lows to highs of around 260°C (500°F).

This thermal stability is crucial for aerospace, chemical processing, and scientific laboratory equipment. Parts made from Teflon can perform reliably in engine components, high-temperature chemical reactors, and sensitive lab instruments.

Understanding the Trade-offs

While its properties are exceptional, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations.

Mechanical Strength Limitations

Teflon is a relatively soft material. It is not suitable for high-load structural applications where rigidity and tensile strength are the primary requirements.

Under sustained pressure, Teflon can be prone to "creep," or slow deformation over time.

Machining Challenges

The softness that contributes to Teflon's low friction can also make it challenging to machine. Holding very tight tolerances requires specialized knowledge and tooling to prevent the material from deforming or creating burrs during the cutting process.

Higher Thermal Expansion

Compared to metals, Teflon has a high coefficient of thermal expansion. Engineers must account for this in designs that will experience significant temperature fluctuations to avoid issues with fit and function.

Making the Right Choice for Your Application

Selecting the right material is about matching its properties to your project's core goal.

- If your primary focus is chemical resistance: Teflon is a top-tier choice for components exposed to aggressive substances, from industrial chemicals to food products.

- If your primary focus is low-friction movement: It is an excellent material for self-lubricating bearings, seals, and gears where wear resistance is key.

- If your primary focus is biocompatibility: Teflon's inertness makes it a standard in medical devices and laboratory equipment where purity is non-negotiable.

- If your primary focus is high structural load: You should evaluate harder plastics or metals, as Teflon's softness is a significant limitation for load-bearing components.

Ultimately, selecting CNC machined Teflon is a strategic decision for applications where its specialized properties solve problems that conventional materials cannot.

Summary Table:

| Industry | Primary Use Case | Key PTFE Property Utilized |

|---|---|---|

| Aerospace | High-voltage insulators, engine components | Electrical insulation, thermal stability |

| Medical | Biocompatible implants, surgical instruments | Chemical inertness, biocompatibility |

| Chemical Processing | Valves, seals, reactor components | Extreme chemical resistance |

| Electronics | Semiconductor manufacturing, cable coatings | Dielectric strength, signal integrity |

| Automotive | Self-lubricating bearings, bushings | Low friction, wear resistance |

| Food Manufacturing | Non-reactive machinery parts | Purity, chemical inertness |

Need High-Performance CNC Machined Teflon Parts?

KINTEK specializes in precision manufacturing of PTFE components for industries where material performance is critical. Whether you're in semiconductor manufacturing, medical device production, or chemical processing, we deliver custom-fabricated seals, liners, and labware that meet your exact specifications.

Why Choose KINTEK?

- Expert Precision: We overcome Teflon's machining challenges to hold tight tolerances

- Custom Solutions: From prototypes to high-volume production runs

- Industry Expertise: Deep understanding of chemical, thermal, and mechanical requirements

Contact our engineering team today to discuss how our CNC machined Teflon parts can solve your most demanding application challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance