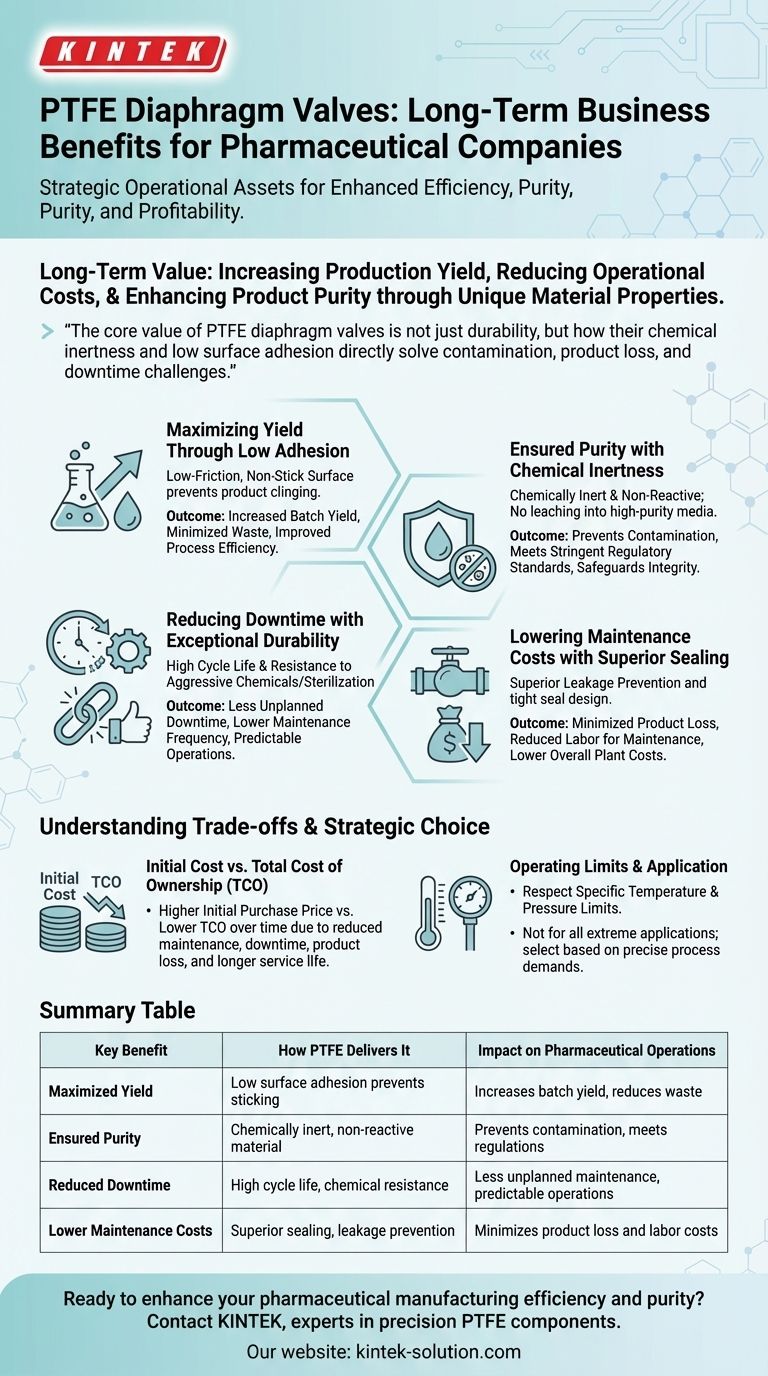

Over the long term, PTFE diaphragm valves provide direct and significant business benefits to pharmaceutical companies by increasing production yield, reducing operational costs, and enhancing product purity. Their unique material properties translate into a lower total cost of ownership and mitigate critical risks inherent in pharmaceutical manufacturing, making them a strategic operational asset rather than a simple component.

The core value of PTFE diaphragm valves is not just their durability, but how their specific material characteristics—chemical inertness and low surface adhesion—directly solve the industry's most pressing challenges of contamination risk, product loss, and process downtime.

How PTFE Properties Drive Business Value

The long-term benefits of PTFE diaphragm valves are a direct result of the polymer's fundamental properties. Understanding this connection is key to appreciating their strategic importance.

Maximizing Yield Through Low Adhesion

One of the most significant challenges in pharmaceutical production is product loss, where valuable materials stick to equipment surfaces.

PTFE has an extremely low-friction, non-stick surface. This low surface adhesion prevents powders, sensitive liquids, and other high-purity substances from clinging to the valve's diaphragm.

This ensures a more complete transfer of product in every batch, directly increasing production yield and minimizing waste. It also improves process efficiency by ensuring smooth, predictable handling of solid and liquid compounds.

Ensuring Purity with Chemical Inertness

Maintaining product purity is non-negotiable in the pharmaceutical industry. The valve material itself cannot react with or contaminate the process media.

PTFE is chemically inert and non-reactive, meaning it will not leach substances into the high-purity media passing through it. This is critical for preventing contamination and ensuring the final product meets stringent regulatory standards.

This property provides a reliable safeguard for product integrity, from research and development through full-scale manufacturing.

Reducing Downtime with Exceptional Durability

Equipment failure and the resulting downtime can halt production and lead to significant financial losses.

PTFE diaphragms offer a high cycle life and exceptional resistance to aggressive chemicals and sterilization processes. This durability means the valves last longer and fail less frequently than many alternatives.

This reliability leads to a direct reduction in unplanned downtime and lowers the frequency of costly maintenance interventions, contributing to more predictable and efficient operations.

Lowering Maintenance Costs with Superior Sealing

Leaks not only result in the loss of valuable product but also create safety hazards and require immediate, costly maintenance.

The design of PTFE-lined diaphragm valves ensures superior leakage prevention and a tight seal. This minimizes the operational costs associated with product loss and reduces the labor required for ongoing maintenance and adjustments.

By providing consistent and reliable flow control without leakage, these valves help lower the overall cost of plant operations.

Understanding the Trade-offs

While highly beneficial, PTFE diaphragm valves are not a universal solution. Acknowledging their context is crucial for proper application.

Initial Cost vs. Total Cost of Ownership (TCO)

High-performance components like PTFE diaphragm valves may have a higher initial purchase price compared to some standard metal or elastomeric alternatives.

However, this upfront cost is consistently offset by a lower Total Cost of Ownership (TCO). The savings come from reduced maintenance, less production downtime, minimized product loss, and a significantly longer service life.

Viewing the valve as a long-term investment is critical to understanding its true financial value.

Operating Temperature and Pressure Limits

PTFE has specific temperature and pressure limitations that must be respected. While its performance is exceptional within its designed range, it is not suitable for all extreme-temperature or high-pressure steam applications.

In such scenarios, specialized metal valves may still be required. The key is to select the valve based on the precise demands of the specific process step, ensuring PTFE is applied where its benefits can be fully realized.

Making the Right Choice for Your Process

Choosing the correct valve technology is a strategic decision that directly impacts your bottom line. Use your primary goal to guide your selection.

- If your primary focus is maximizing product yield and purity: The non-stick, non-reactive nature of PTFE is essential for minimizing material loss and eliminating the risk of contamination.

- If your primary focus is reducing operational costs and downtime: The high durability and reliability of PTFE diaphragms deliver a lower total cost of ownership through less frequent maintenance and replacement.

- If your primary focus is process versatility and safety: PTFE's broad chemical resistance ensures valve integrity and operator safety across a wide range of products and aggressive cleaning agents.

Ultimately, selecting PTFE diaphragm valves is a strategic decision that fortifies the efficiency, purity, and profitability of pharmaceutical manufacturing.

Summary Table:

| Key Benefit | How PTFE Delivers It | Impact on Pharmaceutical Operations |

|---|---|---|

| Maximized Yield | Low surface adhesion prevents product sticking | Increases batch yield, reduces waste |

| Ensured Purity | Chemically inert, non-reactive material | Prevents contamination, meets regulations |

| Reduced Downtime | High cycle life, chemical resistance | Less unplanned maintenance, predictable operations |

| Lower Maintenance Costs | Superior sealing, leakage prevention | Minimizes product loss and labor costs |

Ready to enhance your pharmaceutical manufacturing efficiency and purity?

At KINTEK, we specialize in precision PTFE components, including custom diaphragm valves designed for the demanding environments of the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a solution tailored to maximize your yield and minimize your total cost of ownership.

Contact us today to discuss how our PTFE valves can become a strategic asset for your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- Why is PTFE considered cost-effective for seals and 'O' rings? Achieve Long-Term Savings and Reliability

- What control options are available for PTFE/PFA lined ball valves? Choose the Right Actuation Method

- What is Teflon Lined Carbon Steel Pipe, and what are its properties? A Cost-Effective Solution for Corrosive Fluids

- What are some real-world applications of PTFE coatings? Solve Friction, Corrosion & Contamination

- How are PTFE slide bearings installed in construction projects? A Guide to Methods & Best Practices

- What are the advantages of ceramic fillers over glass reinforcements? Superior Thermal & High-Frequency Performance

- What should be considered when selecting a CNC machining service for PTFE? Key Factors for Precision Parts

- How does the temperature range of PTFE seals benefit various industries? Ensure Reliability from -200°C to 250°C