To properly troubleshoot temperature-related seal issues, you must first verify that your application's true operational temperature—both its minimum and maximum—falls within the seal material's specified service range. If the temperature exceeds the upper limit, the solution is to upgrade to a specialty compound designed for higher heat. If it falls below the lower limit, the fix involves either selecting a more cold-flexible material or implementing environmental controls like insulation or heaters.

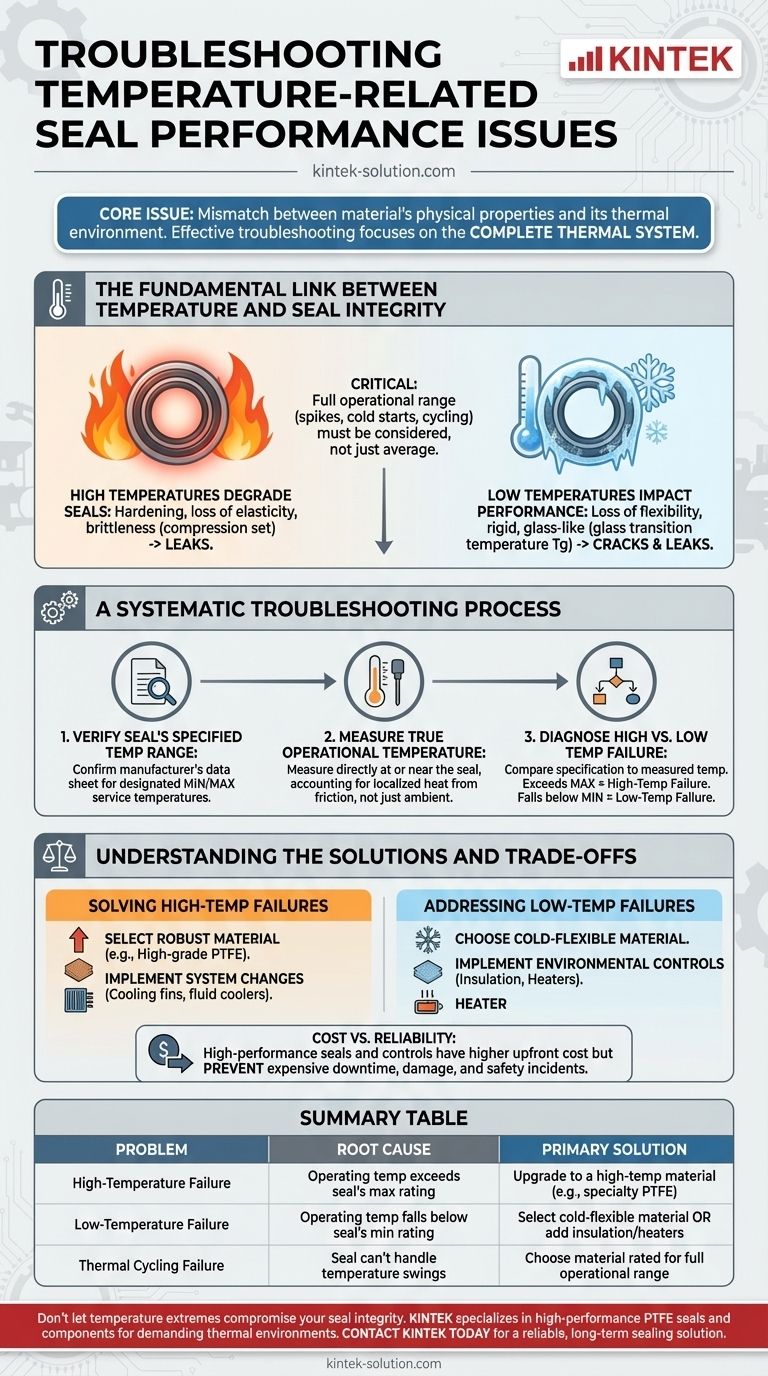

The core issue in temperature-related seal failure is a mismatch between the material's physical properties and its thermal environment. Effective troubleshooting, therefore, focuses not just on the seal itself, but on understanding and controlling the complete thermal system in which it operates.

The Fundamental Link Between Temperature and Seal Integrity

Temperature is one of the most common causes of premature seal failure. Both high and low temperatures fundamentally alter a seal's material properties, compromising its ability to maintain a reliable sealing force.

How High Temperatures Degrade Seals

Excessive heat acts as an accelerant for material aging. It can cause the polymer to harden, lose its elasticity, and become brittle over time.

This loss of flexibility, known as compression set, means the seal can no longer conform to the mating surfaces, leading to inevitable leaks.

The Impact of Low Temperatures on Performance

As temperatures drop, seal materials lose their flexibility and can become rigid and glass-like. This is often referred to as the material's glass transition temperature (Tg).

An embrittled seal may crack under pressure or during dynamic movement. It also lacks the pliability needed to respond to surface imperfections, creating a direct path for leaks.

Why the Full Operational Range is Critical

Focusing only on the average operating temperature is a common mistake. A seal must be ableto perform reliably during temperature spikes, cold starts, and thermal cycling.

The material must be chosen based on the absolute highest and lowest temperatures it will experience, even if those extremes are infrequent.

A Systematic Troubleshooting Process

Instead of guessing, a methodical approach will quickly identify the root cause and the most effective solution.

Step 1: Verify the Seal's Specified Temperature Range

The first step is always to confirm the manufacturer's data sheet for the exact seal you are using. This document will clearly state the material's designed minimum and maximum service temperatures.

If this information is unavailable, you cannot proceed with an accurate diagnosis.

Step 2: Measure the True Operational Temperature

Relying on ambient or system fluid temperature can be misleading. You must measure the temperature directly at or as close as possible to the seal's location.

Friction, especially in dynamic applications, can generate significant localized heat, pushing the seal's temperature far above the rest of the system.

Step 3: Diagnose the High vs. Low Temperature Failure

Once you have compared the seal's specification to its true operating temperature, you can determine the corrective path.

If the operating temperature exceeds the seal's maximum rating, you have a high-temperature failure. If it falls below the minimum rating, you have a low-temperature failure.

Understanding the Solutions and Trade-offs

The solution must address the specific type of thermal failure you have diagnosed. Simply replacing a failed seal with an identical one will only repeat the problem.

Solving High-Temperature Failures

The primary solution is to select a seal made from a more robust material. For example, upgrading from a standard elastomer to a specialty compound like a high-grade PTFE can dramatically increase thermal resistance.

In some cases, system-level changes like adding cooling fins or fluid coolers may be necessary to reduce the temperature at the seal interface.

Addressing Low-Temperature Failures

For low-temperature issues, the first option is to choose a material specifically formulated for cold-temperature flexibility.

If a material change is not feasible, environmental controls become the solution. This can include adding insulation to retain heat or installing small heaters to keep the seal above its critical glass transition temperature during cold starts.

The Cost vs. Reliability Equation

High-performance seals and environmental controls have a higher upfront cost. However, this investment almost always prevents far more expensive unplanned downtime, equipment damage, and safety incidents caused by seal failure.

Making the Right Choice for Your Application

Use your diagnosis to guide your decision-making toward a permanent solution.

- If your primary focus is high-temperature environments: Prioritize selecting a seal material with a thermal range that significantly exceeds your maximum measured operational temperature.

- If your primary focus is low-temperature operation: Focus on materials known for superior low-temperature flexibility and consider adding insulation or heaters to prevent embrittlement.

- If your primary focus is reliability across a wide range: Invest in a premium seal compound, such as a correctly specified PTFE lip seal, that is engineered for your specific thermal profile to prevent future failures.

Ultimately, achieving long-term seal reliability requires a precise alignment between the material's capabilities and the true thermal demands of its environment.

Summary Table:

| Problem | Root Cause | Primary Solution |

|---|---|---|

| High-Temperature Failure | Operating temp exceeds seal's max rating | Upgrade to a high-temp material (e.g., specialty PTFE) |

| Low-Temperature Failure | Operating temp falls below seal's min rating | Select a cold-flexible material or add insulation/heaters |

| Thermal Cycling Failure | Seal can't handle temperature swings | Choose a material rated for the full operational range |

Don't let temperature extremes compromise your seal integrity.

KINTEK specializes in manufacturing high-performance PTFE seals and components—including seals, liners, and labware—designed to withstand demanding thermal environments in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures a perfect match for your application's specific temperature profile, from prototypes to high-volume orders.

Contact KINTEK today for a consultation on a reliable, long-term sealing solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components