In short, the primary advantages of PTFE machined bellows are their universal chemical and corrosion resistance, exceptional performance in extreme conditions, and inherent purity. These qualities make them a superior choice for protecting sensitive equipment from mechanical, chemical, and thermal stress, especially in demanding industries.

The core reason to choose PTFE bellows is for operational certainty. Their unique combination of chemical inertness, durability, and non-stick properties ensures system integrity, minimizes maintenance, and prevents contamination in critical applications.

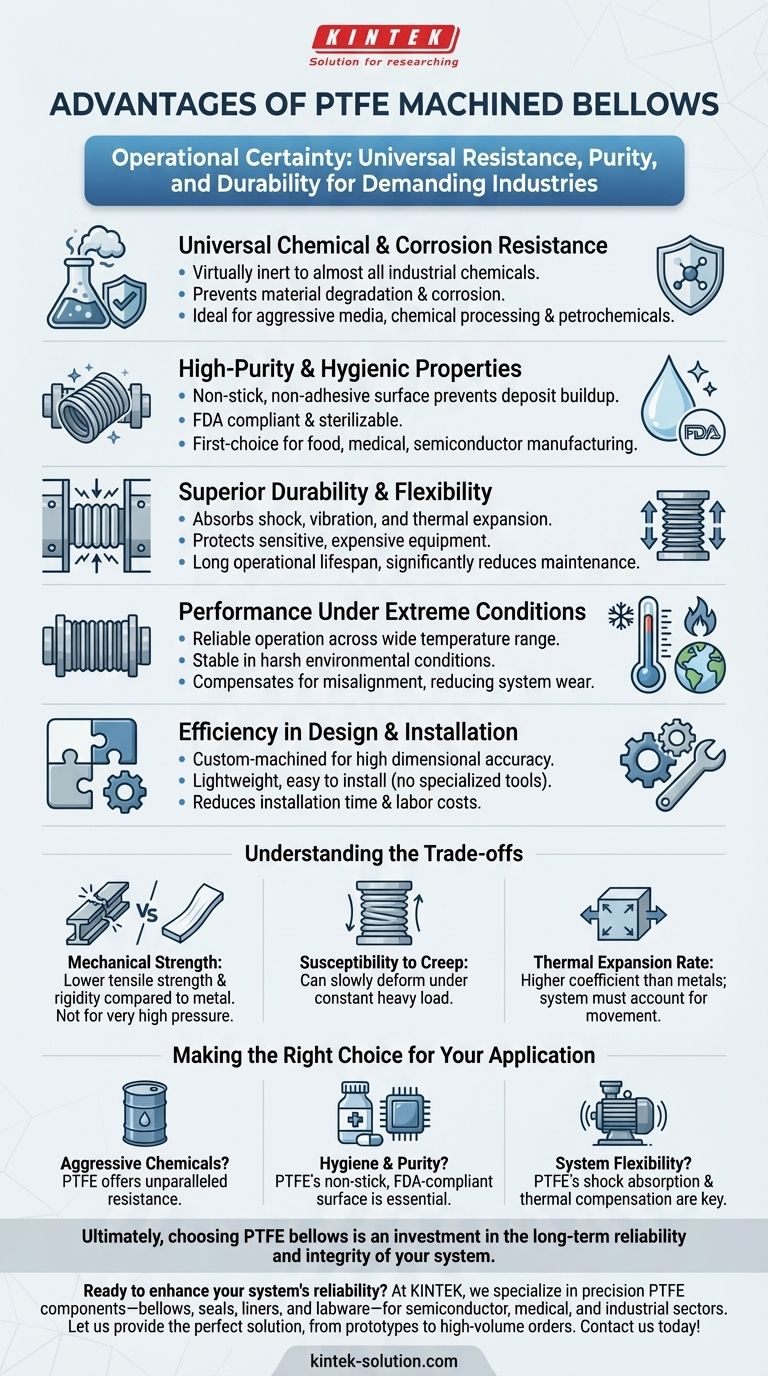

Unpacking the Core Advantages of PTFE Bellows

To understand if PTFE bellows are the right solution, we need to look beyond a simple list of features and examine how each property solves a specific engineering problem.

Universal Chemical and Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals. This makes it an ideal material for components that will be exposed to aggressive or corrosive media.

This stability prevents material degradation, ensuring the bellows maintain their structural integrity and protective function throughout their lifespan. This is critical in sectors like chemical processing and petrochemicals.

High-Purity and Hygienic Properties

PTFE is designed to repel other materials from its surface. This non-stick or non-adhesive property is crucial for preventing deposit buildup and ensuring efficient, clean fluid flow.

This characteristic, combined with FDA compliance and the ability to be sterilized, makes PTFE bellows a first-choice material for food production, medical appliances, and semiconductor manufacturing where purity is non-negotiable.

Superior Durability and Low Maintenance

PTFE bellows function as balancing elements, absorbing shock, vibration, and thermal expansion between system components. This protects sensitive and expensive equipment from damaging stressors.

Their inherent durability translates directly to a long operational lifespan, significantly reducing the need for replacement and lowering overall maintenance costs and system downtime.

Performance Under Extreme Conditions

These components operate reliably across a wide temperature range and are stable in harsh environmental conditions.

Their flexibility allows them to compensate for misalignment and movement, reducing wear and tear on the entire system and ensuring consistent performance even under stress.

Efficiency in Design and Installation

Being custom-machined allows for high dimensional accuracy, ensuring a perfect fit for specific design requirements.

Furthermore, PTFE bellows are lightweight and easy to install, often requiring no specialized tools. This reduces installation time and labor costs compared to heavier, more rigid alternatives.

Understanding the Trade-offs

While PTFE offers a powerful combination of benefits, it's essential to understand its practical limitations to make an informed decision. No material is perfect for every scenario.

Mechanical Strength Considerations

Compared to metal bellows, PTFE has lower tensile strength and rigidity. In applications involving very high pressures or significant physical stress, a metal alternative might be necessary.

Susceptibility to Creep

Under a constant, heavy load, PTFE can be subject to "creep," or slow deformation over time. This must be factored into the design phase for applications involving sustained mechanical stress.

Thermal Expansion Rate

PTFE has a relatively high coefficient of thermal expansion compared to metals. While the bellows are designed to absorb this movement, the surrounding system design must account for this property to avoid undue stress.

Making the Right Choice for Your Application

The decision to use PTFE machined bellows should be driven by the specific demands of your project.

- If your primary focus is handling aggressive chemicals: The unparalleled chemical resistance of PTFE offers the best protection against corrosion and degradation.

- If your primary focus is hygiene and purity: PTFE's non-stick, FDA-compliant surface is essential for preventing contamination in food, medical, or semiconductor applications.

- If your primary focus is system flexibility and vibration dampening: The inherent flexibility and shock absorption of PTFE protect equipment and compensate for thermal expansion and misalignment.

Ultimately, choosing PTFE bellows is an investment in the long-term reliability and integrity of your system.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Chemical Resistance | Inert to virtually all industrial chemicals, preventing corrosion. |

| High Purity | Non-stick, FDA-compliant, and sterilizable for hygienic applications. |

| Durability & Flexibility | Absorbs vibration, thermal expansion, and misalignment, protecting equipment. |

| Performance in Extremes | Reliable operation across a wide temperature range and harsh conditions. |

| Custom & Easy Installation | Machined for precise fit, lightweight, and simple to install, reducing costs. |

Ready to enhance your system's reliability with high-performance PTFE bellows?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom-machined bellows, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components meet the highest standards for chemical resistance, purity, and durability.

Let us provide the perfect solution for your demanding application, from prototypes to high-volume orders. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Which industries benefit from Teflon machined parts? Achieve Peak Performance in Demanding Applications

- How do PTFE sliding bearings work? Support Heavy Loads with Minimal Friction

- What are the typical characteristics and applications of O-ring materials? Find the Right Seal for Extreme Environments

- What are some variations of control valve designs? A Guide to Linear vs. Rotary Motion Valves

- How is Teflon used in thermal breaks in construction? Enhance Building Energy Efficiency with PTFE

- What are the limitations of PTFE coated fasteners regarding abrasion resistance? The Trade-Off for Superior Chemical Protection

- Is a Teflon sheet necessary for all heat press applications? Essential Protection for Consistent Results

- How do PTFE valves perform under high temperatures? Unmatched Thermal Stability for Extreme Environments