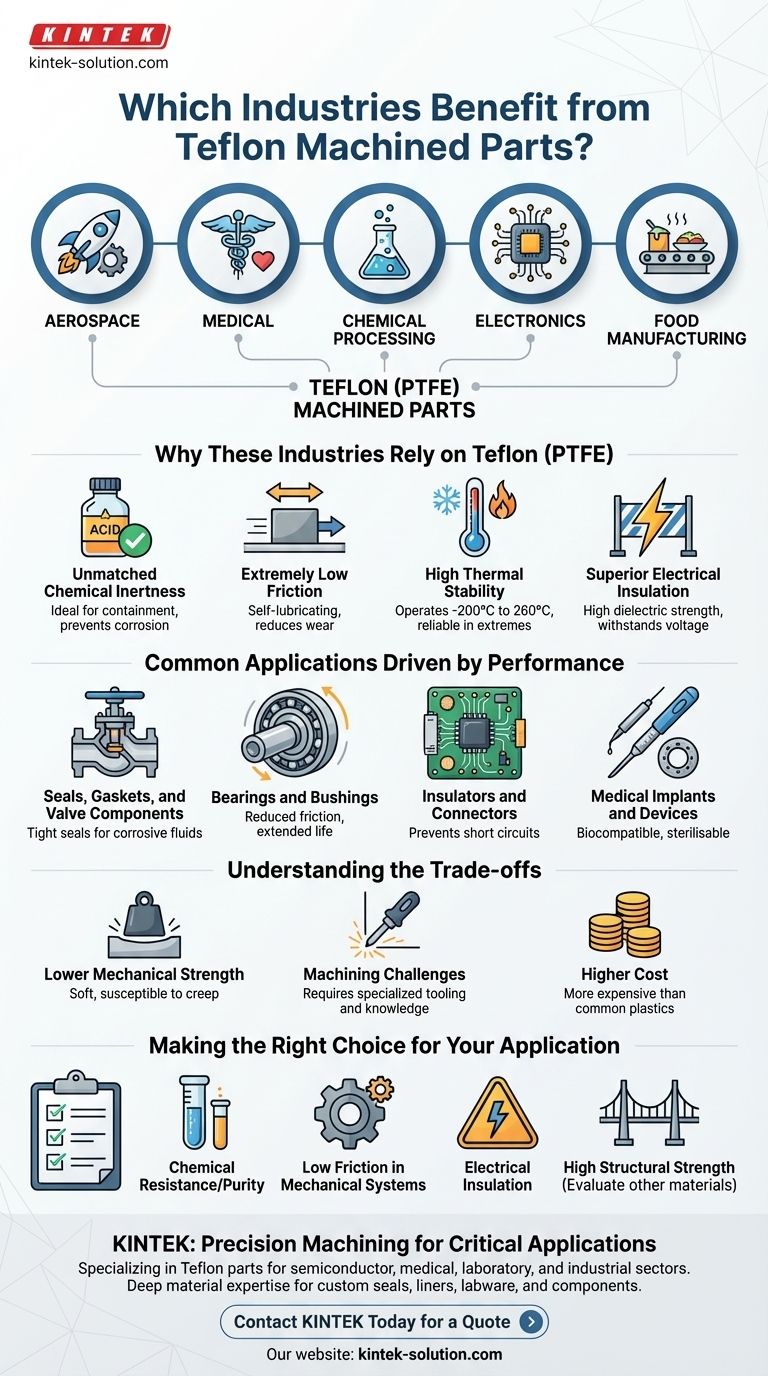

A specific set of high-stakes industries consistently benefit from machined Teflon (PTFE) parts. The most prominent among them are aerospace, medical, chemical processing, electronics, and food manufacturing. These sectors rely on Teflon's unique properties to solve critical engineering challenges where other materials would fail.

The widespread use of Teflon in demanding industries is not a matter of general preference. It is a direct result of its unique combination of chemical inertness, thermal stability, and an extremely low coefficient of friction—properties that are essential for reliability in extreme environments.

Why These Industries Rely on Teflon (PTFE)

The value of machined Teflon parts is directly tied to a set of core material properties. Different industries prioritize different attributes to enhance performance and ensure safety.

Unmatched Chemical Inertness

Teflon is virtually immune to chemical attack. It does not react with aggressive acids, bases, or solvents, making it a critical material for containment and fluid handling.

This property is indispensable for the chemical processing, medical, and laboratory equipment industries, where components must not corrode or contaminate the substances they contact.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" or self-lubricating quality is vital for moving parts.

This is a key advantage in automotive and general industrial applications for components like bearings, gears, and seals, where minimizing wear and resistance is paramount.

High Thermal Stability

Teflon can perform reliably across a wide temperature range, from cryogenic lows to highs of around 260°C (500°F). It maintains its structural integrity and properties where many other plastics would melt or become brittle.

The aerospace and automotive industries heavily leverage this stability for parts that must function near engines or in the extreme temperature variations of space.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down. It also resists surface arcing.

This makes it a go-to material in the electronics and semiconductor industries for manufacturing insulators, connectors, and cable coatings where signal integrity is crucial.

Common Applications Driven by Performance

These properties translate into specific, high-value components that are machined to precise tolerances.

Seals, Gaskets, and Valve Components

Because it is both chemically inert and conformable, Teflon is ideal for creating tight seals in pumps and valves that handle corrosive fluids or operate at high temperatures.

Bearings and Bushings

The low-friction nature of Teflon allows it to be used for bearings and wear pads in mechanical systems, reducing the need for external lubrication and extending the life of machinery.

Insulators and Connectors

In electronics, custom-machined Teflon parts are used to isolate electrical components, preventing short circuits in everything from consumer devices to complex aerospace wiring.

Medical Implants and Devices

Teflon is biocompatible, meaning the human body does not reject it. This, combined with its purity and ability to be sterilized, makes it suitable for implants, surgical instruments, and fluid-handling systems in medical equipment.

Understanding the Trade-offs

While its benefits are significant, Teflon is not a universal solution. An objective assessment requires understanding its limitations.

Lower Mechanical Strength

Compared to engineering plastics like PEEK or metals, Teflon is relatively soft. It can be susceptible to "creep," or deforming under a sustained load, and has lower tensile strength.

Machining Challenges

While easily cut, Teflon's softness and thermal expansion can make holding very tight tolerances a challenge. It requires specialized knowledge and tooling to machine accurately without causing stress or warping.

Higher Cost

As a high-performance polymer, Teflon is more expensive than common plastics like nylon or Delrin. Its use is typically justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is chemical resistance or purity: Teflon is almost certainly the correct choice for wetted components like seals, liners, and fluidic manifolds.

- If your primary focus is low friction in a mechanical system: Teflon is an excellent candidate for bearings, slide plates, and non-stick coatings, especially in moderate-load applications.

- If your primary focus is electrical insulation: Teflon's dielectric properties make it a superior option for high-frequency or high-voltage insulators.

- If your primary focus is high structural strength and rigidity: You should evaluate other materials like PEEK, Torlon, or metals, as Teflon may deform under significant mechanical stress.

Ultimately, choosing Teflon is a decision to prioritize performance and reliability in environments where failure is not an option.

Summary Table:

| Industry | Primary Benefit of Teflon Parts | Common Applications |

|---|---|---|

| Chemical Processing | Unmatched chemical inertness | Seals, gaskets, valve components, liners |

| Medical & Laboratory | Chemical inertness, biocompatibility, purity | Implants, surgical tools, fluid handling systems |

| Aerospace & Automotive | High thermal stability, low friction | Bearings, bushings, insulators, high-temp seals |

| Electronics & Semiconductor | Superior electrical insulation | Connectors, insulators, cable coatings |

| Food Manufacturing | Non-stick properties, purity, chemical resistance | Non-stick surfaces, seals, gaskets |

Need high-performance PTFE components for your critical application?

KINTEK specializes in precision machining of Teflon parts for the semiconductor, medical, laboratory, and industrial sectors. We leverage our deep material expertise to overcome machining challenges, ensuring your custom seals, liners, labware, and other components meet the exacting standards required for reliability in extreme environments.

From prototypes to high-volume production, we deliver the quality and performance your industry demands. Contact KINTEB today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments