At its most fundamental level, a PTFE sliding bearing works by exploiting the exceptionally low friction between a Polytetrafluoroethylene (PTFE) surface and a polished stainless steel plate. This simple mechanism allows two connected structural elements to slide past each other with minimal resistance while simultaneously supporting immense vertical loads.

A PTFE sliding bearing is an engineering solution designed to solve a fundamental structural problem: how to support immense vertical weight while allowing for controlled horizontal movement. It achieves this by pairing the high compressive strength of PTFE with its uniquely low coefficient of friction against polished steel.

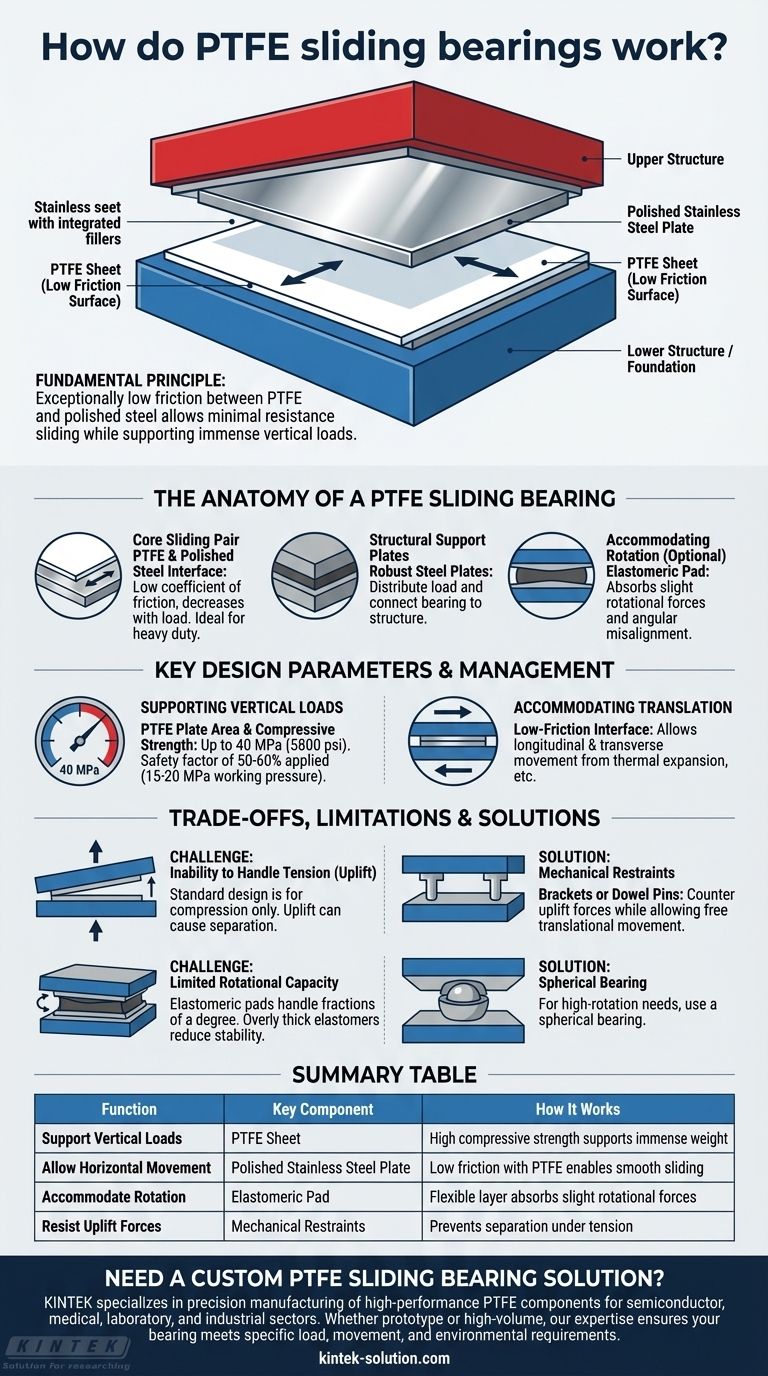

The Anatomy of a PTFE Sliding Bearing

To understand how these bearings function, it’s essential to look at their core components. The design is elegantly simple but highly effective.

The Core Sliding Pair

The heart of the bearing is the interface between two materials: PTFE and polished stainless steel.

A sheet of PTFE, often enhanced with fillers to improve its mechanical properties, is bonded to a steel backing plate. This PTFE surface slides against a highly polished stainless steel plate, which is welded to the opposing structural member.

PTFE has the lowest coefficient of friction of any known solid, and this value actually decreases as the load increases, making it ideal for heavy-duty applications.

The Structural Support Plates

The PTFE and stainless steel layers are bonded or welded to robust steel plates. These plates distribute the structural load over the bearing surface and provide the means to connect the bearing to the larger structure.

Accommodating Rotation with Elastomers

For applications where slight rotation or angular misalignment is expected, an elastomeric pad (like neoprene or silicone) is often incorporated into the bearing assembly. This flexible layer can deform to absorb small rotational forces that the rigid PTFE cannot.

Key Design Parameters and How They Are Managed

A manufacturer designs a PTFE bearing based on specific parameters provided by the client. Each parameter dictates a different aspect of the bearing's construction.

Supporting Vertical Loads

This is the bearing's primary load-bearing function. The design focuses on the area of the PTFE plate and its exceptional compressive strength, which can be double that of materials like neoprene.

While pure PTFE can handle pressures up to 40 MPa (around 5800 psi), engineers typically apply a safety factor of 50-60%, designing for a working pressure of 15-20 MPa to ensure long-term reliability.

Accommodating Translation

Permitting horizontal movement (translation) is the core reason for using a sliding bearing. The low-friction interface allows for longitudinal and transverse movement caused by thermal expansion, material creep, or other dynamic forces.

Understanding the Trade-offs and Limitations

While highly effective, PTFE sliding bearings have specific limitations that must be addressed in the design. Objectivity requires acknowledging what they cannot do on their own.

Inability to Handle Tension (Uplift)

A standard sliding bearing is designed only for compression. It has no inherent ability to resist uplift forces, such as those caused by heavy winds on a bridge or roof.

If uplift occurs, the sliding plates can separate, leading to misalignment or complete dislodgement of the bearing.

Solutions for Uplift

To counter uplift, the bearing must be mechanically restrained. This is typically achieved with brackets or T-shaped dowel pins.

These stainless steel pins are strong enough to handle the tensile loads, while the gaps in their slots are engineered to allow free translational movement without compromising the restraint.

Limited Rotational Capacity

A standard PTFE bearing is not designed for significant rotation. While thin elastomeric pads can manage fractions of a degree, they are not a solution for high-rotation joints.

Using an overly thick elastomer to absorb more rotation can introduce stability issues. For high-rotation needs, a spherical bearing is often the more appropriate technical choice.

Making the Right Choice for Your Application

Choosing the correct bearing configuration depends entirely on the specific forces your structure must manage.

- If your primary focus is high vertical load with simple horizontal movement: A standard PTFE-on-steel bearing is the most direct and cost-effective solution.

- If your design involves slight rotation or misalignment: Specify a bearing that incorporates an elastomeric layer like neoprene to absorb these rotational forces.

- If your structure is exposed to uplift forces from wind or mechanics: Ensure the design includes mechanical restraints like T-shaped dowel pins or brackets to prevent dislodgement.

By understanding these core principles, you can confidently specify a bearing solution that precisely matches your structural demands.

Summary Table:

| Function | Key Component | How It Works |

|---|---|---|

| Support Vertical Loads | PTFE Sheet | High compressive strength (up to 40 MPa) supports immense weight. |

| Allow Horizontal Movement | Polished Stainless Steel Plate | Low coefficient of friction with PTFE enables smooth sliding. |

| Accommodate Rotation | Elastomeric Pad (e.g., Neoprene) | Flexible layer absorbs slight rotational forces. |

| Resist Uplift Forces | Mechanical Restraints (e.g., Dowel Pins) | Prevents bearing separation under tension. |

Need a custom PTFE sliding bearing solution for your project?

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom sliding bearings for the semiconductor, medical, laboratory, and industrial sectors. Whether you require a prototype or a high-volume order, our expertise ensures your bearing is engineered to handle your specific load, movement, and environmental requirements.

Contact us today to discuss your application and receive a solution that delivers superior performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications