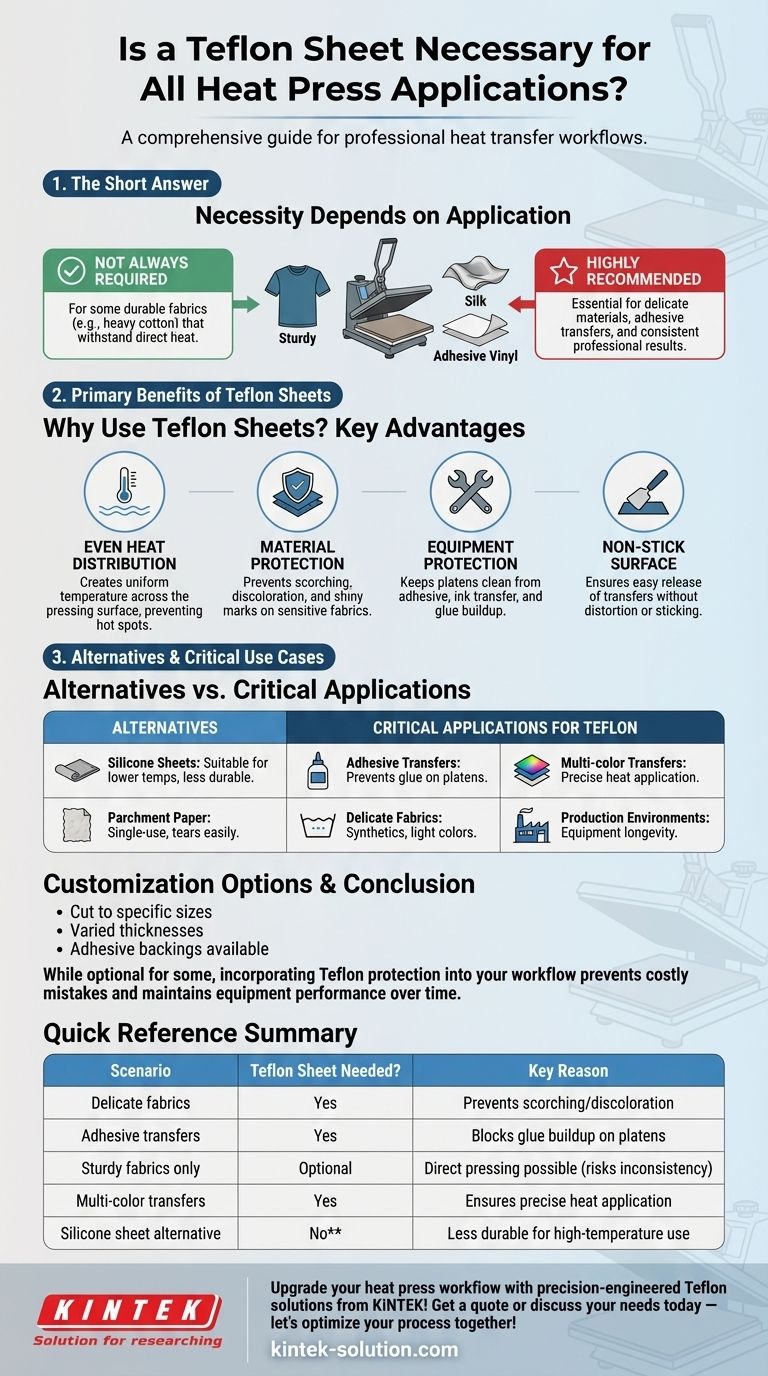

Teflon sheets are not strictly necessary for all heat press applications, but they offer significant advantages that make them highly recommended in most cases. While some durable fabrics may withstand direct heat pressing without protection, Teflon sheets provide essential safeguards for both materials and equipment. Their non-stick properties prevent adhesive transfer, ensure even heat distribution, and protect delicate fabrics from scorching. Alternatives like silicone sheets or parchment paper exist but lack the durability and performance consistency of Teflon. For professional results and equipment longevity, using an adhesive teflon sheet proves valuable across most heat transfer scenarios.

Key Points Explained:

-

Necessity Depends on Application

- Not absolutely required for all materials (some durable fabrics can withstand direct pressing)

- Becomes essential for delicate fabrics prone to scorching or when using adhesives

- Recommended for maintaining consistent professional results across different material types

-

Primary Benefits of Teflon Sheets

- Heat Distribution: Creates uniform temperature across entire pressing surface

- Material Protection: Prevents scorching, discoloration, and shiny marks on fabrics

- Equipment Protection: Keeps platens clean from adhesive/ink transfer

- Non-Stick Surface: Allows easy release without material distortion

-

When Alternatives Might Suffice

- Silicone sheets: Suitable for lower-temperature applications but less durable

- Parchment paper: Works for single-use applications but tears easily

- Direct pressing: Possible with some sturdy fabrics but risks inconsistent results

-

Critical Applications Requiring Teflon

- Adhesive transfers (prevents glue buildup on platens)

- Delicate fabrics (synthetics, light colors, specialty materials)

- Multi-color transfers requiring precise heat application

- Production environments where equipment protection is paramount

-

Customization Options

- Can be cut to specific platen sizes

- Available in different thicknesses for varied applications

- Some feature adhesive backings for secure placement

- Can be combined with other protective layers as needed

The decision ultimately depends on your specific materials, transfer types, and quality requirements. While you might skip the sheet for occasional simple transfers, incorporating Teflon protection into your standard workflow prevents costly mistakes and maintains equipment performance over time. Consider how often you change materials and whether you can risk transfer inconsistencies when deciding whether to make it a permanent part of your process.

Summary Table:

| Scenario | Teflon Sheet Needed? | Key Reason |

|---|---|---|

| Delicate fabrics | Yes | Prevents scorching and discoloration |

| Adhesive transfers | Yes | Blocks glue buildup on platens |

| Sturdy fabrics only | Optional | Direct pressing possible but risks inconsistency |

| Multi-color transfers | Yes | Ensures precise heat application |

| Silicone sheet alternative | No* | *Less durable for high-temperature use |

Upgrade your heat press workflow with precision-engineered Teflon solutions from KINTEK! Whether you're protecting delicate fabrics, ensuring adhesive-free platens, or seeking custom-cut sheets for specialized applications, our PTFE components deliver unmatched durability and performance. Get a quote or discuss your needs today — let’s optimize your process together!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE considered the best material for heavy-duty cable liners? Achieve Superior Reliability & Efficiency

- Why are PTFE envelope gaskets suitable for high temperature-pressure conditions? Superior Sealing for Extreme Applications

- What are the limitations of virgin PTFE for rotary shaft seals? Overcome Weakness with Filled Compounds

- Can PTFE rods be machined into complex shapes? Yes, with precision engineering for custom parts.

- Are PTFE V-Rings customizable? Engineer a Perfect Seal for Your Unique Application

- What industries benefit most from PTFE coatings? Unlock Superior Performance in Demanding Environments

- What affects the thickness tolerance of PTFE gasket sheets? The Critical Role of Manufacturing Process

- What materials are used in the construction of PTFE lined ball valves? A Guide to Corrosion-Resistant Components