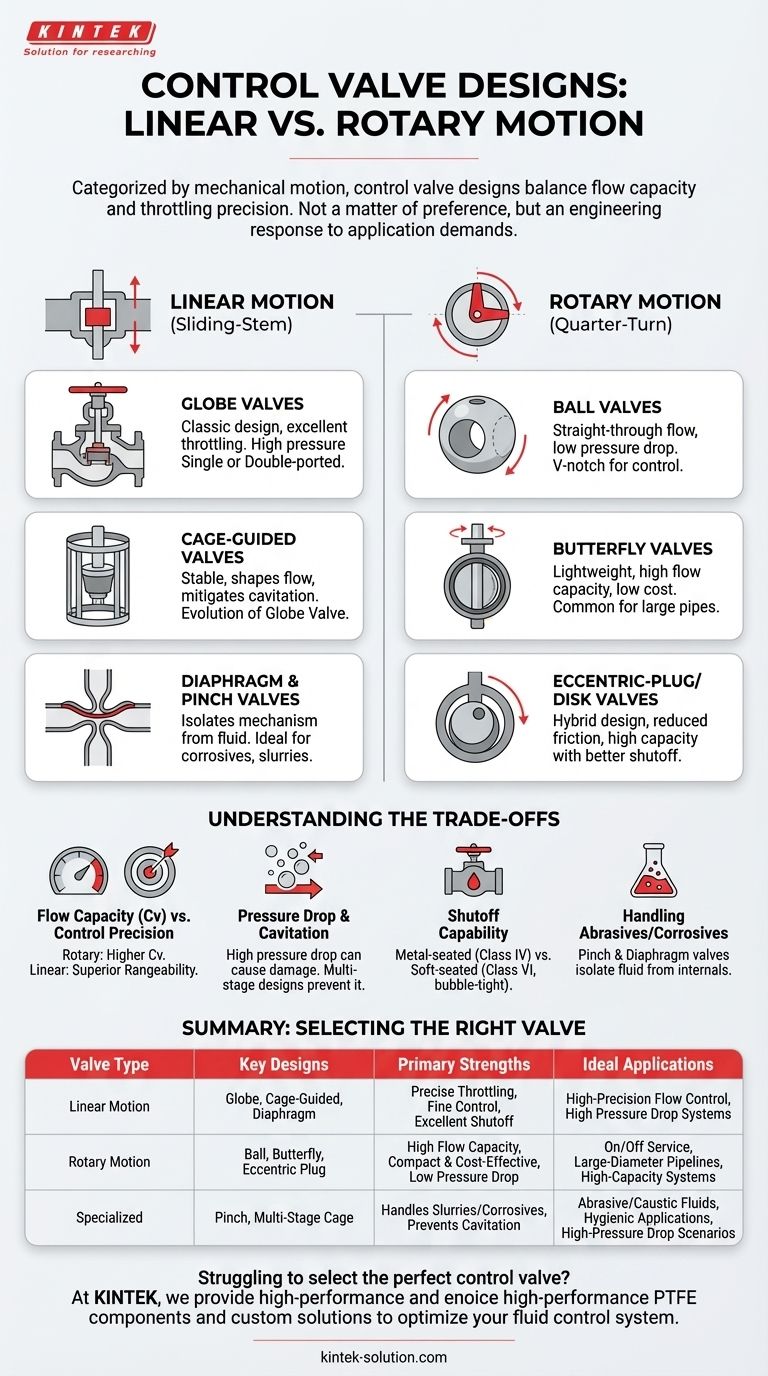

At a glance, the world of control valves appears as a vast and complex list of designs, but they can be fundamentally categorized by their mechanical motion. The primary variations are linear motion valves, where a stem moves a closure element up and down, and rotary motion valves, where the closure element rotates to modulate flow. Designs like globe, cage, and diaphragm valves are linear, while ball, butterfly, and plug valves are rotary.

The specific design of a control valve is not a matter of preference but a direct engineering response to the demands of the application. The core trade-off is almost always between a valve's maximum flow capacity and its precision in throttling that flow.

The Two Fundamental Valve Motions

To understand control valve variations, it's best to start with their core mechanical action. Every design falls into one of two families: linear or rotary.

Linear Motion (Sliding-Stem) Valves

These valves use a push-pull action, where a stem moves a plug or diaphragm into or out of a seat. They are often the first choice for applications requiring precise throttling and control over a wide range of conditions.

Key Linear Valve Designs

-

Globe Valves: This is the classic control valve design, excellent for throttling flow. The S-shaped body forces the fluid to change direction, which allows for fine control but also creates a higher pressure drop.

- Single-ported designs provide excellent, tight shutoff capability.

- Double-ported designs "balance" the forces on the plug, allowing a smaller actuator to control higher pressure flows, though they typically do not offer tight shutoff.

-

Cage-Guided Valves: An evolution of the globe valve, these designs use a hollow, cylindrical "cage" to guide the valve plug. The cage adds stability against vibration and, more importantly, its machined holes can shape the flow characteristic and mitigate the damaging effects of cavitation.

-

Diaphragm & Pinch Valves: In these designs, a flexible diaphragm or a rubber sleeve is actuated to pinch off the flow path. Their primary advantage is that the valve mechanism is completely isolated from the process fluid, making them ideal for corrosive liquids, slurries, or hygienic applications.

Rotary Motion Valves

Rotary valves use a closure element that turns through a 90-degree arc (a quarter-turn) to open or close the flow path. They are generally simpler, more compact, and offer higher flow capacity for their size compared to linear valves.

The 90-Degree Turn Principle

The key benefit of rotary motion is a straight-through flow path, which results in very little pressure drop when the valve is fully open. This makes them highly efficient for on/off service or for control in systems where high capacity is essential.

Key Rotary Valve Designs

-

Ball Valves: A ball with a hole through it rotates to align with the pipe for open flow or turn perpendicular to it to block flow. For control applications, a V-notch ball valve is used, where the V-shaped cutout in the ball allows for much more gradual and precise flow modulation than a standard round port.

-

Butterfly Valves: A simple disk rotates on a central shaft within the pipe. They are lightweight, low-cost, and offer very high flow capacity, making them common in large-diameter pipelines for water, air, and gas.

-

Eccentric-Plug & Eccentric-Disk Valves: These are hybrid designs. The plug or disk moves in an eccentric (off-center) path, pulling away from the seat as it opens. This action reduces friction and wear while still providing the high capacity of a rotary valve and better shutoff than a conventional butterfly valve.

Understanding the Trade-offs: Why So Many Designs?

The sheer number of valve designs exists to solve specific engineering challenges. Choosing a valve involves balancing competing priorities.

Flow Capacity (Cv) vs. Control Precision (Rangeability)

A valve's flow coefficient (Cv) measures its maximum capacity. Rotary valves generally offer a higher Cv for a given pipe size. However, precision (rangeability) is the measure of how well a valve can control flow at the low end. Globe valves typically offer superior rangeability.

Pressure Drop and Cavitation

High pressure drops can create cavitation—the formation and collapse of vapor bubbles—which can severely damage valve internals. Specialized cage-guided and disk-stack style valves are engineered with multi-stage flow paths that break a large pressure drop into smaller, manageable steps to prevent this.

Shutoff Capability

Not all control valves are designed for zero-leakage shutoff. A Class IV shutoff, common for metal-seated globe valves, allows a very small amount of leakage. For applications requiring bubble-tight closure (Class VI), a soft-seated valve like a diaphragm or eccentric-plug design is necessary.

Handling Abrasives or Corrosives

When the fluid is abrasive or highly corrosive, the goal is to protect the valve's working parts. Pinch valves and diaphragm valves excel here because the fluid never touches the stem or actuator assembly.

Selecting the Right Valve Category for Your Application

Your choice should be guided by the primary demand of your system.

- If your primary focus is precise throttling and fine control: Start with linear motion valves like globe or cage-guided designs.

- If your primary focus is high flow capacity at a lower cost, especially in large pipes: Look to rotary valves like butterfly or V-notch ball valves.

- If your primary focus is handling slurries, corrosive fluids, or requiring zero process contamination: The clear choice is a diaphragm or pinch valve.

- If your primary focus is managing a high pressure drop without damage: Your solution lies in specialized multi-stage valves, such as advanced cage-guided or disk-stack designs.

Understanding these core design families transforms the challenge from memorizing a list to strategically matching a valve's capabilities to your operational goals.

Summary Table:

| Valve Type | Key Designs | Primary Strengths | Ideal Applications |

|---|---|---|---|

| Linear Motion | Globe, Cage-Guided, Diaphragm | Precise Throttling, Fine Control, Excellent Shutoff | High-Precision Flow Control, Systems with High Pressure Drop |

| Rotary Motion | Ball, Butterfly, Eccentric Plug | High Flow Capacity, Compact & Cost-Effective, Low Pressure Drop | On/Off Service, Large-Diameter Pipelines, High-Capacity Systems |

| Specialized | Pinch, Multi-Stage Cage | Handles Slurries/Corrosives, Prevents Cavitation | Abrasive/Caustic Fluids, Hygienic Applications, High-Pressure Drop Scenarios |

Struggling to select the perfect control valve for your demanding application?

At KINTEK, we understand that the right valve design is critical for system performance, longevity, and safety. Whether you require components for high-precision semiconductor manufacturing, corrosive chemical processing in a lab, or robust industrial fluid handling, our expertise in advanced materials like PTFE can provide the solution.

We specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—that enhance valve reliability and compatibility with aggressive media. From prototyping to high-volume production, we prioritize precision to meet your exact specifications.

Let us help you optimize your fluid control system. Contact our engineering team today for a consultation on custom PTFE solutions tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Microwave Digestion Vessels for Demanding Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Custom Machined Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Parts Manufacturer Adjustable Height Flower Basket

People Also Ask

- What happens when clearance develops in a PTFE-lined bearing? A Guide to Catastrophic Failure

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- How are PTFE sheets utilized in the electrical industry? For Superior Insulation and Signal Integrity

- What are the advantages of PTFE diaphragms? Achieve Unmatched Chemical & Thermal Resistance

- What types of equipment commonly use ePTFE gaskets? Solve Your Toughest Sealing Challenges

- How does PTFE perform when bearing surfaces become contaminated? Maintain Reliable Performance in Unclean Environments

- What are the key properties of PTFE heat press sheets? Ensure Flawless, Non-Stick Heat Transfers

- What are the three most common machining processes for Teflon? Master CNC Turning, Milling & Drilling