In short, a PTFE T-seal is a specialized sealing component designed for high-performance industrial applications. It combines the unique T-shaped geometry, which provides a stable and effective seal against irregular surfaces, with the advanced properties of its material, Polytetrafluoroethylene (PTFE). These seals are typically used in demanding environments involving extreme temperatures, aggressive chemicals, or high pressures where standard rubber seals would quickly fail.

While the "T" shape solves a specific mechanical challenge, the true value of these components comes from the PTFE material itself. Its resistance to heat, chemicals, and friction makes it the definitive choice for critical applications in industries from aerospace to chemical processing.

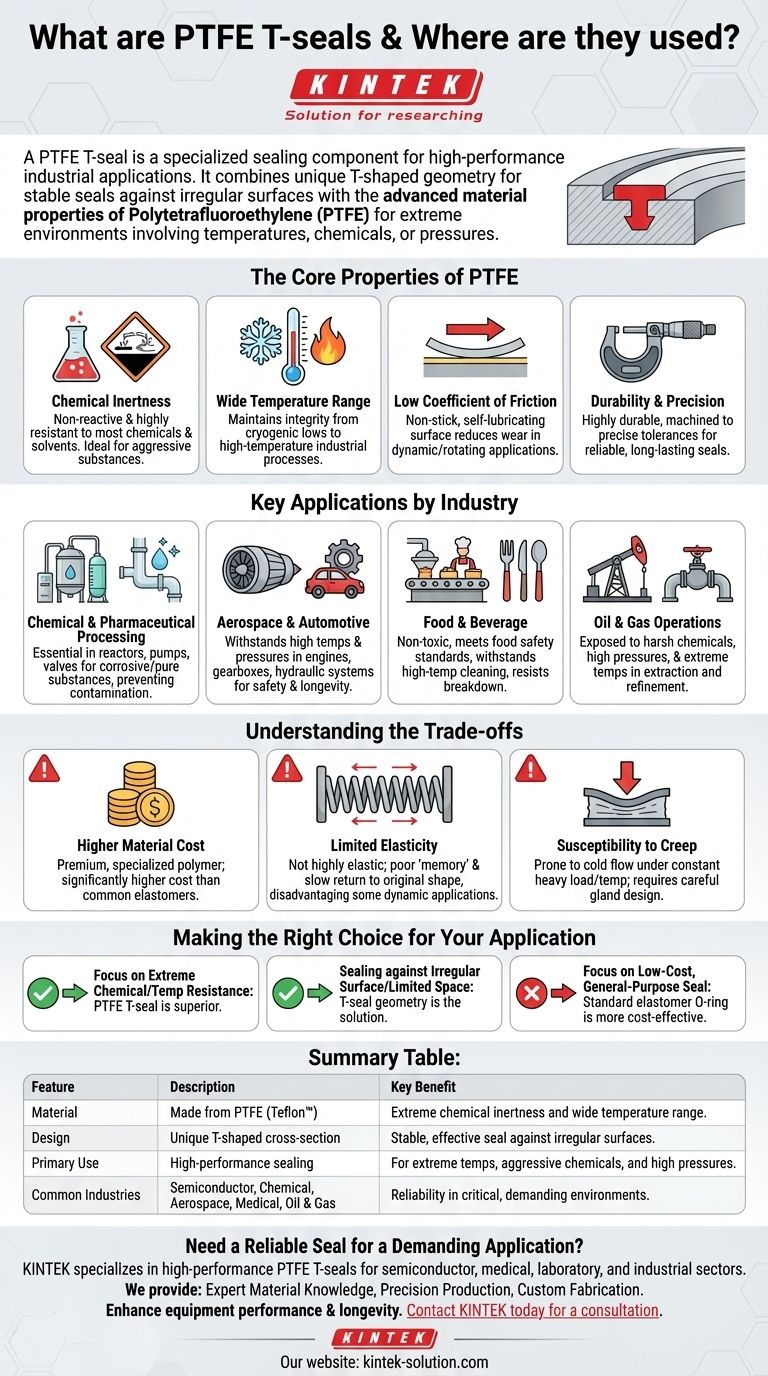

The Core Properties of PTFE

To understand where and why T-seals are used, you must first understand the material they are made from. PTFE, often known by the brand name Teflon, is a high-performance fluoropolymer with a unique combination of characteristics.

Chemical Inertness

PTFE is non-reactive and highly resistant to corrosion from most chemicals and solvents. This makes it ideal for equipment that handles aggressive substances.

Wide Temperature Range

The material maintains its integrity and performance across an exceptionally broad temperature spectrum, from cryogenic lows to high-temperature industrial processes.

Low Coefficient of Friction

PTFE has one of the lowest friction values of any solid material, creating a "non-stick," self-lubricating surface. This is critical for reducing wear and tear in dynamic or rotating applications like pumps and gearboxes.

Durability and Precision

As a material, PTFE is highly durable and can be machined to precise tolerances. This ensures it holds its shape under pressure and provides a reliable, long-lasting seal.

Key Applications by Industry

The properties of PTFE dictate where these seals are most effective. They are specified for environments where performance and reliability are non-negotiable.

Chemical and Pharmaceutical Processing

Due to its extreme chemical resistance, PTFE seals are essential in reactors, pumps, and valves that handle corrosive or pure substances without causing contamination.

Aerospace and Automotive

In high-performance engines, gearboxes, and hydraulic systems, PTFE seals withstand high temperatures and pressures, ensuring operational safety and longevity.

Food and Beverage

PTFE is non-toxic and meets food safety standards. Its ability to withstand high-temperature cleaning processes and resist chemical breakdown makes it suitable for processing equipment.

Oil and Gas Operations

These seals are used in downhole tools, valves, and pumps where they are exposed to harsh chemicals, high pressures, and extreme temperatures found in extraction and refinement.

Understanding the Trade-offs

No material is perfect for every situation. Choosing a PTFE T-seal involves acknowledging its specific limitations compared to more common sealing materials.

Higher Material Cost

PTFE is a premium, specialized polymer. Its cost is significantly higher than that of common elastomers like Nitrile (Buna-N) or EPDM rubber.

Limited Elasticity

Unlike rubber, PTFE is not highly elastic and has poor "memory." It does not spring back to its original shape as effectively, which can be a disadvantage in applications requiring constant dynamic adjustment.

Susceptibility to Creep

Under a constant, heavy load (especially at elevated temperatures), PTFE can be prone to "creep," or cold flow, where the material slowly deforms over time. This must be accounted for in the design of the gland or housing.

Making the Right Choice for Your Application

Your decision should be driven by the operational demands of the equipment, not just the component's name.

- If your primary focus is extreme chemical or temperature resistance: PTFE is the superior material choice, and a T-seal geometry provides a stable platform for it.

- If you are sealing against an irregular surface or in a limited space: The specific geometry of a T-seal is designed to solve this exact problem effectively.

- If your primary focus is a low-cost, general-purpose seal for a stable environment: A standard elastomer O-ring is likely a more cost-effective and suitable solution.

Ultimately, selecting a PTFE T-seal is a decision to prioritize performance and longevity in environments where failure is not an option.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Material | Made from PTFE (Teflon™) | Extreme chemical inertness and wide temperature range |

| Design | Unique T-shaped cross-section | Stable, effective seal against irregular surfaces |

| Primary Use | High-performance sealing | For extreme temps, aggressive chemicals, and high pressures |

| Common Industries | Semiconductor, Chemical Processing, Aerospace, Medical, Oil & Gas | Reliability in critical, demanding environments |

Need a Reliable Seal for a Demanding Application?

When standard seals fail under extreme temperatures, aggressive chemicals, or high pressures, a precision PTFE T-seal from KINTEK is the solution. We specialize in manufacturing high-performance PTFE components, including custom T-seals, for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Material Knowledge: Leveraging PTFE's full potential for your specific challenges.

- Precision Production: Components machined to exact tolerances for a perfect, reliable fit.

- Custom Fabrication: From initial prototypes to high-volume production orders.

Let us help you enhance the performance and longevity of your equipment.

Contact KINTEK today for a consultation to discuss your sealing requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the advantages of PTFE with a Proven Inorganic Filler? Maximize Metal Component Lifespan

- What environmental conditions can Teflon seals withstand? Master Extreme Temperatures & Chemicals

- What other applications benefit from PTFE lubrication? Solve Extreme Lubrication & Sealing Challenges

- What are the key advantages of PTFE oil seals over conventional oil seals? Superior Performance for Extreme Conditions

- What are PTFE liners and why are they considered a breakthrough in medical sciences? Discover the Key to Safer Medical Devices

- How can the right PTFE gasket improve equipment service life? Extend Lifespan with Superior Protection

- Why are PTFE lined valves considered a reliable choice for industrial processes? Achieve Unmatched Chemical Resistance & Longevity

- How does CNC turning work for PTFE, and what precautions are necessary? Achieve Precision Machining