Teflon seals are renowned for their robust performance in harsh environments, capable of withstanding a broad temperature range from cryogenic conditions up to approximately 120°C (250°F). Critically, they exhibit exceptional resistance to nearly all industrial chemicals, including strong acids, alkalis, and powerful oxidizers.

At its core, Teflon's value lies not in a single attribute, but in its rare ability to resist both extreme temperatures and aggressive chemical attack simultaneously, a combination that few other sealing materials can match.

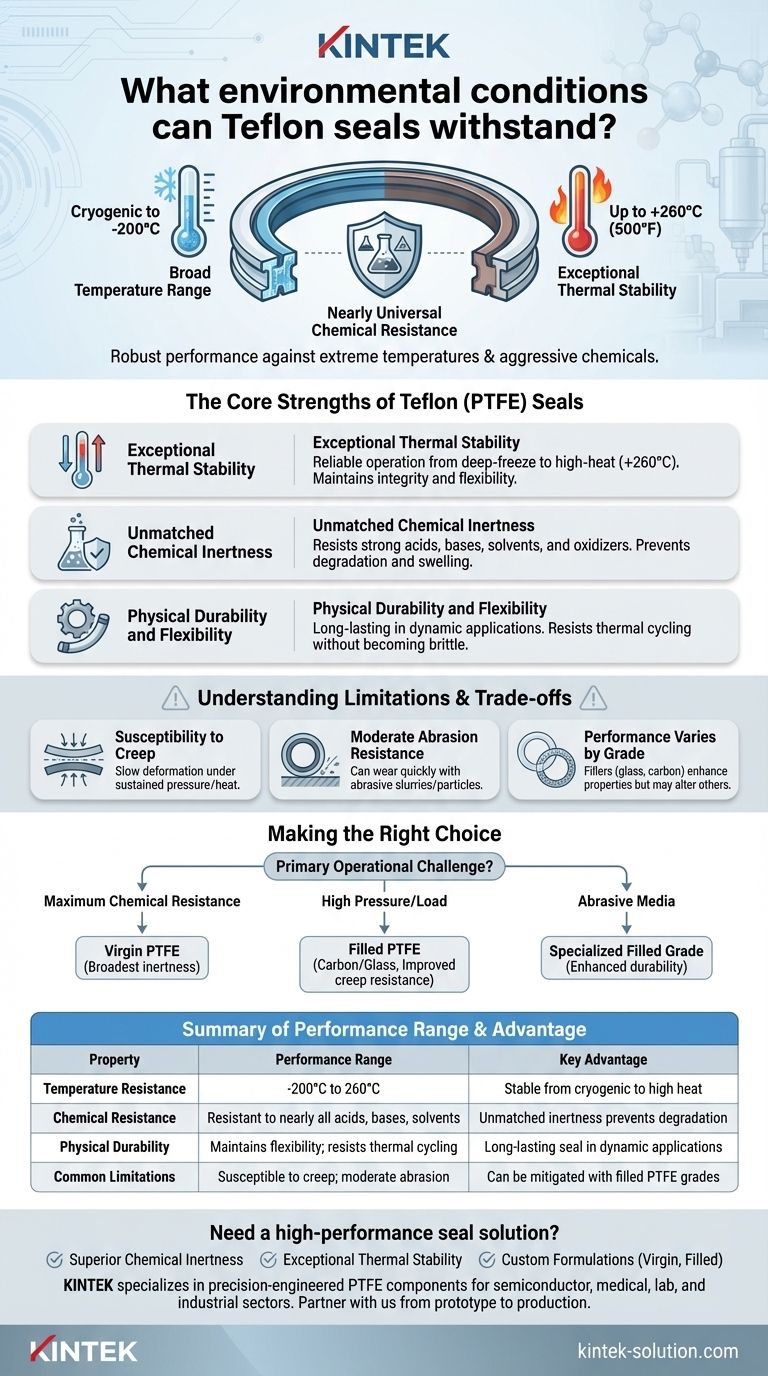

The Core Strengths of Teflon (PTFE) Seals

Polytetrafluoroethylene (PTFE), the material behind the Teflon™ brand, possesses a unique molecular structure that gives it powerful defensive characteristics. Understanding these properties is key to deploying it effectively.

Exceptional Thermal Stability

Teflon seals operate reliably across a vast temperature spectrum. They maintain their integrity and flexibility in deep-freeze applications and can handle continuous service temperatures often cited around 120°C.

It is important to note that specific grades of PTFE can perform at much higher temperatures, often up to 260°C (500°F), making it a premier choice for high-heat processes.

Unmatched Chemical Inertness

The carbon-fluorine bonds in PTFE are incredibly strong, making the material almost universally inert. This allows it to seal effectively against the most corrosive substances found in industrial settings.

This resistance applies to strong acids, bases, solvents, and oxidizers, preventing the degradation, swelling, or breakdown that can cause seal failure with other elastomers.

Physical Durability and Flexibility

Beyond its environmental resistance, Teflon is a durable material that maintains its flexibility. This ensures a consistent, long-lasting seal even in dynamic applications or where thermal cycling occurs.

This physical resilience prevents the seal from becoming brittle at low temperatures or overly soft at high temperatures, ensuring reliable performance across its operational range.

Understanding the Limitations and Trade-offs

While exceptionally capable, no material is perfect. A true technical assessment requires acknowledging Teflon's potential limitations in certain scenarios.

Susceptibility to Creep

Under sustained pressure, especially at elevated temperatures, unfilled (virgin) PTFE can be susceptible to "creep" or cold flow. This is a slow deformation of the material that can eventually compromise sealing integrity.

Moderate Abrasion Resistance

PTFE is a relatively soft material. In applications involving abrasive slurries or high-particulate media, it can wear more quickly than harder materials.

Performance Varies by Grade

The term "Teflon" covers various grades of PTFE. Fillers like glass, carbon, or graphite are often added to enhance specific properties like creep resistance or hardness, but these can slightly alter the material's chemical resistance or temperature limits.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to your primary operational challenge.

- If your primary focus is maximum chemical resistance: Virgin PTFE is the ideal choice, offering the broadest possible inertness.

- If your application involves high pressure or mechanical loads: Consider a carbon or glass-filled PTFE grade to significantly improve resistance to creep.

- If you are sealing against abrasive media: A specialized filled grade will provide the necessary durability to ensure a long service life.

By understanding both its profound strengths and specific limitations, you can confidently specify Teflon seals for your most demanding environments.

Summary Table:

| Property | Performance Range | Key Advantage |

|---|---|---|

| Temperature Resistance | -200°C to 260°C (-328°F to 500°F) | Stable from cryogenic to high heat |

| Chemical Resistance | Resistant to nearly all acids, bases, solvents | Unmatched inertness prevents degradation |

| Physical Durability | Maintains flexibility; resists thermal cycling | Long-lasting seal in dynamic applications |

| Common Limitations | Susceptible to creep under pressure; moderate abrasion resistance | Can be mitigated with filled PTFE grades |

Need a seal that can handle your most demanding environment?

KINTEK specializes in manufacturing high-performance PTFE components, including seals, liners, and custom labware. Whether your application is in the semiconductor, medical, laboratory, or industrial sector, we provide precision-engineered solutions that deliver:

- Superior Chemical Inertness: Confidently seal against aggressive acids, alkalis, and solvents.

- Exceptional Thermal Stability: Ensure reliable performance from deep-freeze to high-temperature processes.

- Custom Formulations: Choose from virgin PTFE for maximum chemical purity or filled grades (glass, carbon) for enhanced creep and abrasion resistance.

We partner with you from prototype to high-volume production to ensure your seals meet exact specifications. Let's solve your sealing challenge together—contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How do PTFE-lined butterfly valves minimize maintenance requirements? Reduce Downtime and Extend Service Life

- How should PTFE-lined bearings be maintained? The Essential Guide to Maintenance-Free Operation

- What tools are used in the CNC machining of PTFE? Achieve Clean, Precise Cuts

- How do spring-energized PTFE seals perform in high-pressure environments? Unlock Superior Sealing Reliability

- In what types of applications are PTFE oil seals commonly used? Essential for Extreme Conditions

- In which industries are PTFE washers commonly used? Essential for Aerospace, Medical, and Chemical Processing

- How is PTFE used in structural sliding bearings? Enable Smooth Movement Under Immense Loads

- What are the challenges and recommendations for machining Teflon? Master Precision PTFE Fabrication