Beyond its common uses, PTFE's unique properties make it a critical material for high-performance lubrication and sealing across a vast range of demanding industries. Its applications extend from industrial machinery and chemical processing equipment to critical components in the aerospace and automotive sectors, where reliability under extreme conditions is non-negotiable.

The true value of PTFE is not just its low friction, but its ability to maintain that property while resisting extreme temperatures and harsh chemicals, making it a go-to problem-solver in environments where conventional lubricants fail.

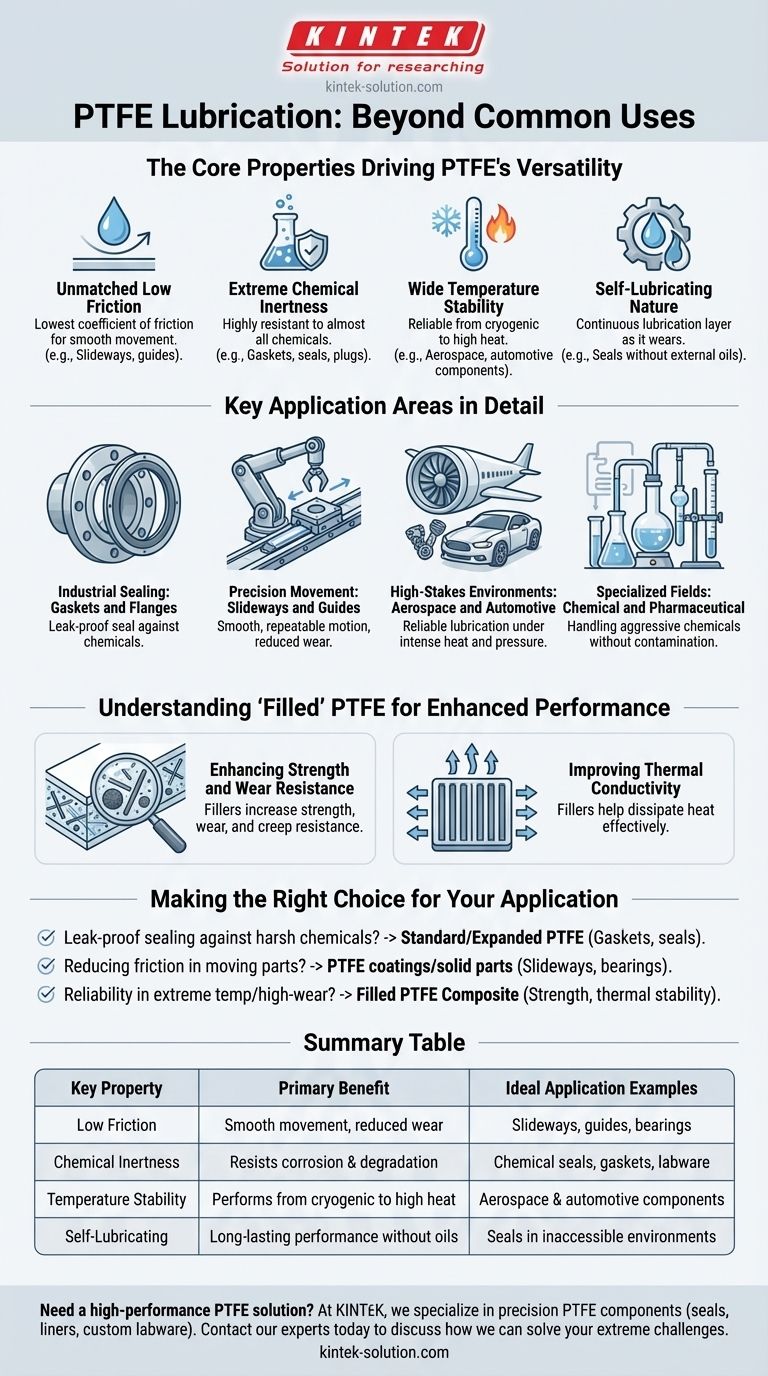

The Core Properties Driving PTFE's Versatility

To understand where PTFE excels, we must first understand its fundamental characteristics. These properties work in concert to deliver performance that few other materials can match.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This intrinsic slipperiness is the primary reason it is used in applications requiring smooth, effortless movement.

This property is essential for components like slideways and guides in precision machinery, where it reduces wear and energy consumption.

Extreme Chemical Inertness

PTFE is highly resistant to almost all chemicals and solvents. This makes it an ideal material for use in corrosive environments where other materials would quickly degrade.

This inertness is why it's used for gaskets, seals, and plugs in chemical processing equipment, laboratories, and industrial piping systems.

Wide Temperature Stability

PTFE maintains its integrity and lubricating properties over a very broad temperature range. It performs reliably in both cryogenic conditions and high-heat applications.

This stability is critical for aerospace and automotive components that experience drastic temperature fluctuations during operation.

Self-Lubricating Nature

As a solid lubricant, PTFE provides a continuous lubricating layer as it wears. This self-lubricating characteristic ensures consistent performance over the component's lifespan without the need for external oils or greases.

Key Application Areas in Detail

These core properties enable PTFE to be deployed in a variety of critical systems where failure is not an option.

Industrial Sealing: Gaskets and Flanges

PTFE's ability to create a leak-proof seal while resisting chemicals is invaluable. Expanded PTFE is specifically engineered to seal flange joints in pipelines, hydraulic systems, and even delicate glass or plastic pressure vessels.

Precision Movement: Slideways and Guides

In manufacturing and automation, components must move with minimal resistance. PTFE coatings and solid parts are used for slideways and guides to ensure smooth, repeatable motion and reduce mechanical wear.

High-Stakes Environments: Aerospace and Automotive

Both aerospace and automotive industries rely on materials that perform under extreme stress. PTFE is used in a variety of components where reliable lubrication under intense heat and pressure is essential for safety and performance.

Specialized Fields: Chemical and Pharmaceutical

The chemical inertness of PTFE makes it essential for laboratory and pharmaceutical applications. PTFE plugs, seals, and linings are used to handle aggressive chemicals without risk of contamination or material degradation.

Understanding "Filled" PTFE for Enhanced Performance

While pure PTFE is highly effective, its properties can be enhanced by adding other materials, creating what is known as filled PTFE.

Enhancing Strength and Wear Resistance

Fillers like glass fiber, carbon, or bronze are added to the PTFE matrix to significantly increase its strength and resistance to wear and creep. This makes it suitable for more demanding mechanical applications.

Improving Thermal Conductivity

Adding fillers can also improve PTFE's thermal conductivity, allowing it to dissipate heat more effectively in high-speed or high-load applications. This further extends its usefulness in challenging environments.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary challenge you need to solve.

- If your primary focus is leak-proof sealing against harsh chemicals: Standard or expanded PTFE is the ideal choice for gaskets, seals, and flange joints.

- If your primary focus is reducing friction in moving parts: PTFE coatings or solid components are perfect for slideways, guides, and bearings.

- If your primary focus is reliability in extreme temperatures or high-wear conditions: A filled PTFE composite will provide the necessary strength and thermal stability.

Ultimately, PTFE's versatility allows it to be engineered into a precise solution for nearly any high-performance lubrication or sealing challenge.

Summary Table:

| Key Property | Primary Benefit | Ideal Application Examples |

|---|---|---|

| Low Friction | Smooth movement, reduced wear | Slideways, guides, bearings |

| Chemical Inertness | Resists corrosion & degradation | Chemical seals, gaskets, labware |

| Temperature Stability | Performs from cryogenic to high heat | Aerospace & automotive components |

| Self-Lubricating | Long-lasting performance without oils | Seals in inaccessible or clean environments |

Need a high-performance PTFE solution for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the chemical resistance of pure PTFE or the enhanced strength of a filled composite, our custom fabrication services from prototypes to high-volume orders ensure you get a reliable solution tailored to your exact needs.

Contact our experts today to discuss how we can solve your extreme lubrication and sealing challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the compressive strength of bronze-filled PTFE? A Guide to High-Strength PTFE for Mechanical Parts

- How is PTFE used in the automotive industry? Enhancing Vehicle Reliability and Performance

- What pressure considerations apply to PTFE lined butterfly valves? Avoid Liner Failure and Ensure Safe Operation

- What are the basic types of PTFE Teflon gaskets? Choose the Right Seal for Your Application

- How does the low friction coefficient of PTFE coatings affect tightening torque? Achieve Accurate Clamping Force Safely

- What are the benefits of 55% Bronze + 5% MoS2-filled PTFE bushings? Achieve Superior Performance in High-Load Applications

- What are the key performance capabilities of spring energized PTFE seals? Conquer Extreme Environments

- What are the limitations when machining Teflon/PTFE? Overcome Dimensional Instability & Creep