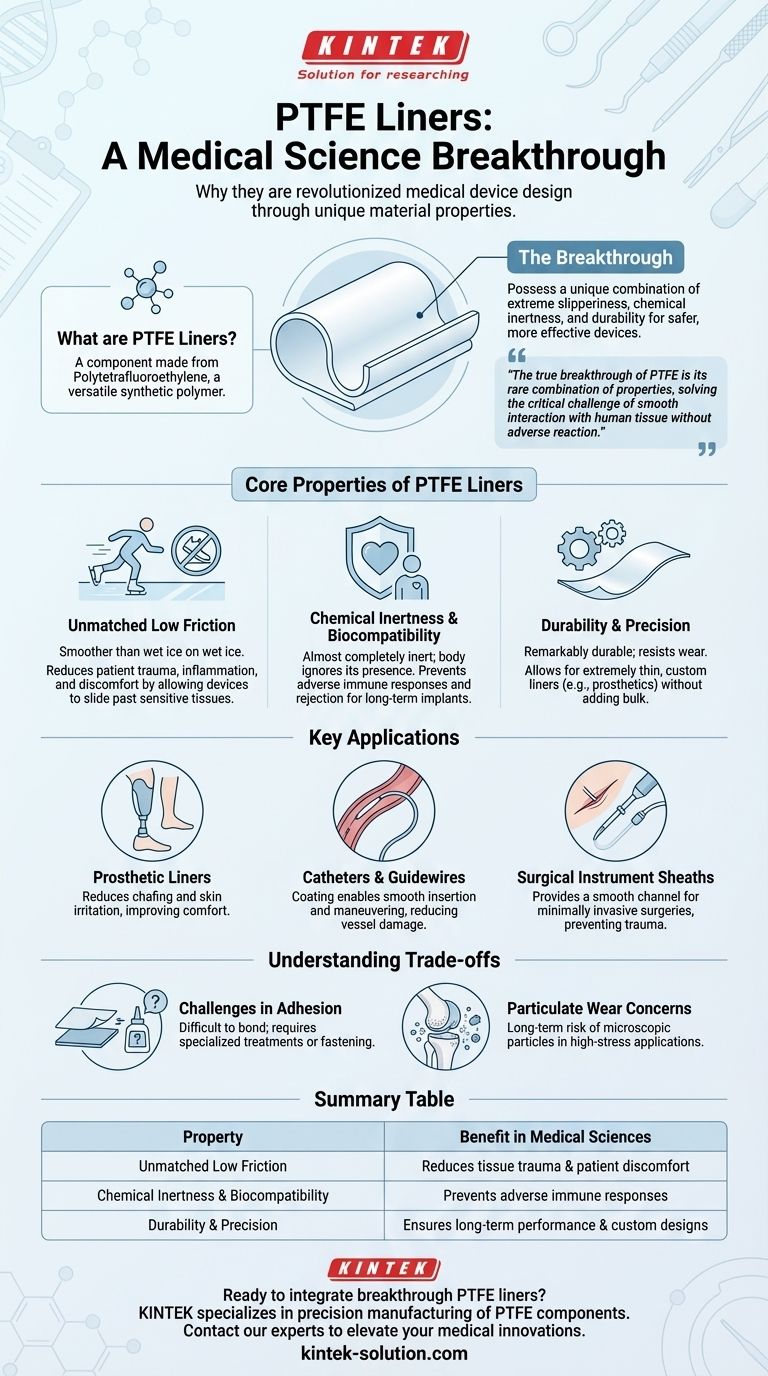

At its core, a PTFE liner is a component made from Polytetrafluoroethylene, a highly versatile synthetic polymer. These liners are considered a breakthrough in medical science because they possess a unique combination of extreme slipperiness, chemical inertness, and durability, allowing for the creation of safer, more comfortable, and more effective medical devices.

The true breakthrough of PTFE isn't a single feature, but its rare combination of properties. It solves the critical medical challenge of creating devices that can move smoothly against or within human tissue without causing irritation, damage, or an adverse biological reaction.

The Core Properties of PTFE Liners

To understand the impact of PTFE, we must look at the specific material characteristics that make it invaluable in a medical context. It's the synergy of these properties that enables innovation.

Unmatched Low Friction

A PTFE liner's most famous characteristic is its incredibly low coefficient of friction. Think of it as being smoother than wet ice on wet ice.

This property is not just a convenience; it is a critical safety feature. It allows medical devices to slide past sensitive tissues with minimal resistance, reducing patient trauma, inflammation, and discomfort during procedures.

Chemical Inertness and Biocompatibility

PTFE is almost completely inert, meaning it does not react with bodily fluids or tissues. The human body effectively ignores its presence.

This biocompatibility is essential for any device that comes into contact with the body, from temporary surgical tools to long-term implants. It prevents adverse immune responses, rejection, and other complications.

Durability and Precision

Despite its smooth surface, PTFE is a remarkably durable and tough material. It resists wear and tear, ensuring the device functions as intended over its entire lifespan.

Furthermore, it can be manufactured into extremely thin liners or coatings. This allows it to be integrated into complex devices without adding significant bulk or weight, as seen in customizable prosthetic liners that conform perfectly to an individual's needs.

Key Applications in Medical Devices

The properties of PTFE translate directly into tangible benefits across a range of medical applications, enhancing both patient outcomes and procedural efficiency.

Prosthetic Liners

In prosthetics, a PTFE liner serves as the critical interface between the patient's residual limb and the socket of the prosthetic. Its low-friction surface dramatically reduces chafing and skin irritation, significantly improving comfort and wearability.

Catheters and Guidewires

When navigating the delicate and complex pathways of blood vessels, friction is the enemy. Coating catheters and guidewires with PTFE allows them to be inserted and maneuvered with greater ease and precision, reducing the risk of vessel damage.

Surgical Instrument Sheaths

Many minimally invasive surgeries rely on introducing instruments through small incisions. A PTFE sheath or liner provides a smooth channel, allowing surgeons to insert, manipulate, and exchange tools without causing unnecessary trauma to the surrounding tissue.

Understanding the Trade-offs

No material is perfect, and relying on PTFE requires an understanding of its limitations. Acknowledging these trade-offs is key to proper engineering and device design.

Challenges in Adhesion

Because PTFE is so non-reactive and slippery, it is notoriously difficult to bond to other materials. Attaching a PTFE liner to a different substrate requires specialized surface treatments or mechanical fastening methods, which can add complexity and cost to the manufacturing process.

Particulate Wear Concerns

In very high-stress, high-cycle applications (such as in the articulating surfaces of some joint implants), there is a long-term risk of microscopic PTFE particles wearing off. While the material is inert, the accumulation of these particles in the body over decades is a factor that engineers must consider and mitigate.

How to Apply This to Device Design

Choosing the right material is about aligning its properties with your primary goal. The versatility of PTFE serves several distinct objectives in medical technology.

- If your primary focus is patient comfort and safety: Use PTFE to create smooth, non-irritating surfaces for devices that have direct, prolonged contact with skin or internal tissues.

- If your primary focus is procedural efficiency: Apply PTFE coatings to instruments that must navigate complex anatomical pathways, reducing friction to enable smoother, faster, and less traumatic procedures.

- If your primary focus is long-term biocompatibility: Leverage PTFE's inertness for implantable components where avoiding a host-body reaction is the most critical requirement.

Understanding the fundamental principles of a material like PTFE empowers you to create safer, more effective solutions to complex medical challenges.

Summary Table:

| Property | Benefit in Medical Sciences |

|---|---|

| Unmatched Low Friction | Reduces tissue trauma and patient discomfort during procedures. |

| Chemical Inertness & Biocompatibility | Prevents adverse immune responses for implants and tools. |

| Durability & Precision | Ensures long-term device performance and custom, thin-walled designs. |

Ready to integrate breakthrough PTFE liners into your medical device designs?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the medical, semiconductor, laboratory, and industrial sectors. Our expertise ensures your devices achieve superior biocompatibility, patient comfort, and procedural efficiency, from prototype to high-volume production.

Contact our experts today to discuss your specific requirements and elevate your medical innovations with high-performance PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application