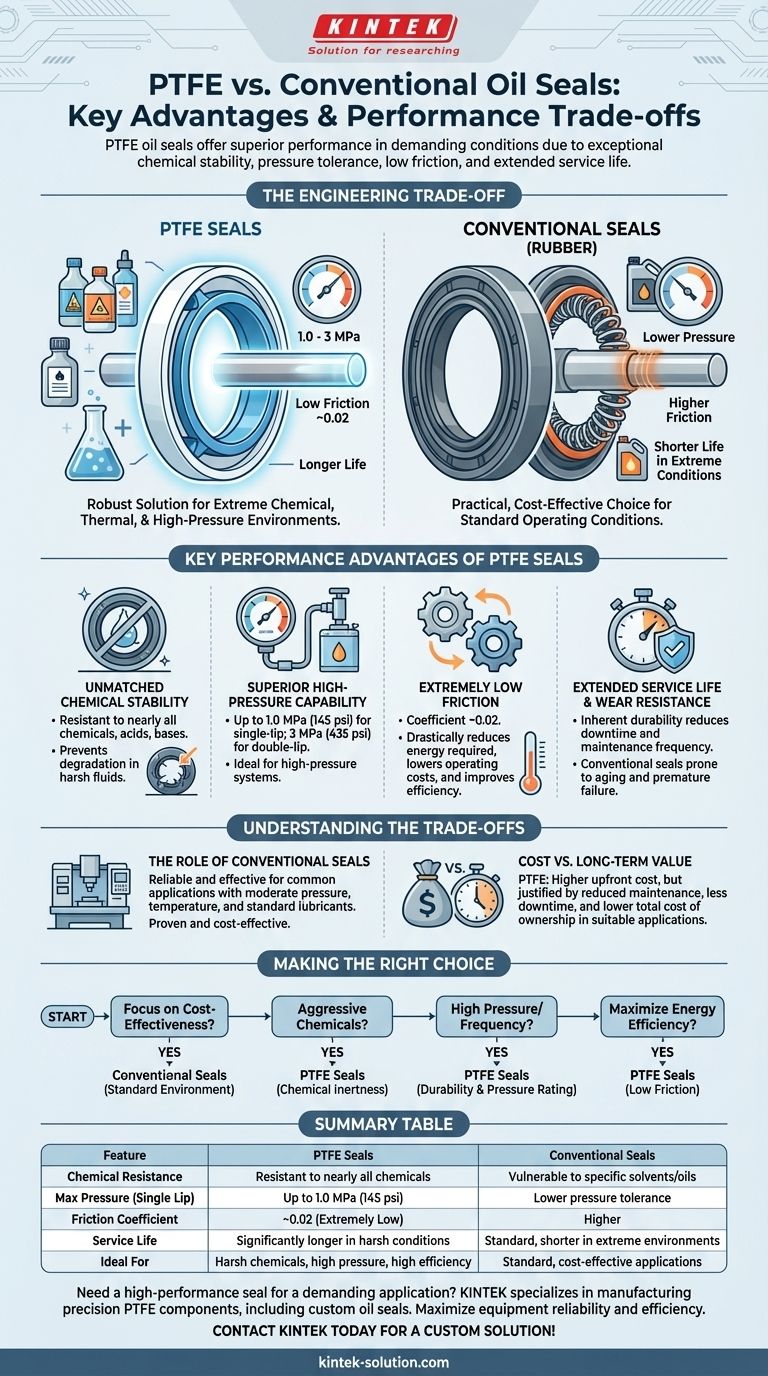

PTFE oil seals offer superior performance in demanding conditions due to their exceptional chemical stability, higher pressure tolerance, extremely low friction, and significantly longer service life. Unlike conventional rubber seals, which are well-suited for general use, PTFE seals are engineered to withstand harsh operational environments where standard materials would quickly fail.

The choice between PTFE and conventional oil seals is a classic engineering trade-off. While PTFE provides a robust solution for extreme chemical, thermal, and high-pressure environments, conventional seals remain the practical, cost-effective choice for standard operating conditions.

Key Performance Advantages of PTFE Seals

Polytetrafluoroethylene (PTFE) is a high-performance polymer that gives these seals distinct advantages over traditional materials like rubber or polyurethane. These benefits become critical in applications that push beyond standard operational limits.

Unmatched Chemical Stability

PTFE is resistant to nearly all chemicals, including strong acids, bases, and aggressive oxidants. This chemical inertness prevents the seal from degrading, swelling, or failing when exposed to harsh fluids.

Conventional rubber seals, in contrast, are vulnerable to specific solvents and oils that can cause them to deteriorate, compromising their sealing capability.

Superior High-Pressure Capability

PTFE seals are engineered to handle significantly higher system pressures. A single-lip PTFE seal can typically withstand up to 1.0 MPa (145 psi), while double-lip designs can manage pressures up to 3 MPa (435 psi).

This makes them the clear choice for high-pressure hydraulic and mechanical systems where conventional seals would be extruded or leak.

Extremely Low Friction

The friction coefficient of PTFE is remarkably low, around 0.02. This characteristic drastically reduces the energy required to turn a shaft, leading to lower operating costs and improved equipment efficiency.

Conventional seals have a higher friction coefficient, which generates more heat during operation. This heat can accelerate the aging of the seal material and increase wear on both the seal and the shaft.

Extended Service Life and Wear Resistance

The inherent durability and wear resistance of PTFE contribute to a much longer service life, especially in high-frequency and high-pressure applications.

This longevity reduces equipment downtime and maintenance frequency. Conventional seals are more prone to aging and hardening over time, particularly in harsh environments, leading to premature leakage and failure.

Understanding the Trade-offs

While the performance benefits of PTFE are clear, they are not the universal solution. A proper technical evaluation requires acknowledging the role and value of conventional seals.

The Role of Conventional Seals

Conventional rubber or polyurethane oil seals perform reliably and effectively in a vast number of common applications. For machinery operating under moderate pressure, temperature, and with standard lubricants, they provide excellent sealing.

Their proven track record and lower cost make them the default, practical choice for less demanding scenarios.

Cost vs. Long-Term Value

The primary trade-off is cost. PTFE seals have a higher upfront purchase price due to the more complex material and manufacturing process.

However, in a suitable application, this initial investment is often justified by reduced maintenance, less downtime, and a longer operational lifespan, resulting in a lower total cost of ownership.

Making the Right Choice for Your Application

Selecting the correct seal material is critical for ensuring equipment reliability and performance. Your decision should be guided by the specific demands of your operating environment.

- If your primary focus is cost-effectiveness in a standard environment: Conventional rubber seals provide reliable performance without the higher upfront investment.

- If your application involves aggressive chemicals or solvents: The chemical inertness of PTFE is non-negotiable to prevent seal degradation and failure.

- If you are dealing with high pressure or high-frequency motion: PTFE's durability and superior pressure rating will deliver a much longer service life.

- If maximizing energy efficiency is a key goal: The exceptionally low friction of PTFE seals minimizes energy loss and heat generation during operation.

By aligning the seal's material properties with your specific operational demands, you ensure both reliability and long-term value.

Summary Table:

| Feature | PTFE Seals | Conventional Seals |

|---|---|---|

| Chemical Resistance | Resistant to nearly all chemicals | Vulnerable to specific solvents/oils |

| Max Pressure (Single Lip) | Up to 1.0 MPa (145 psi) | Lower pressure tolerance |

| Friction Coefficient | ~0.02 (Extremely Low) | Higher |

| Service Life | Significantly longer in harsh conditions | Standard, shorter in extreme environments |

| Ideal For | Harsh chemicals, high pressure, high efficiency | Standard, cost-effective applications |

Need a high-performance seal for a demanding application?

KINTEK specializes in manufacturing precision PTFE components, including custom oil seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a seal that delivers superior chemical stability, handles extreme pressures, reduces friction, and extends service life—maximizing your equipment's reliability and efficiency.

Let us help you solve your toughest sealing challenges. Contact KINTEK today for a custom solution!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals