In short, PTFE lined valves are reliable because their core material properties directly solve the most common and costly industrial challenges. The exceptional chemical resistance, durability, and non-stick surface of Polytetrafluoroethylene (PTFE) create a robust barrier that protects the valve's structure from aggressive media, reduces maintenance, and ensures process purity.

The true value of PTFE lining is not just its ability to resist corrosion. It’s about creating a stable, predictable, and low-maintenance flow control system that enhances safety and lowers the total cost of ownership over the equipment's lifespan.

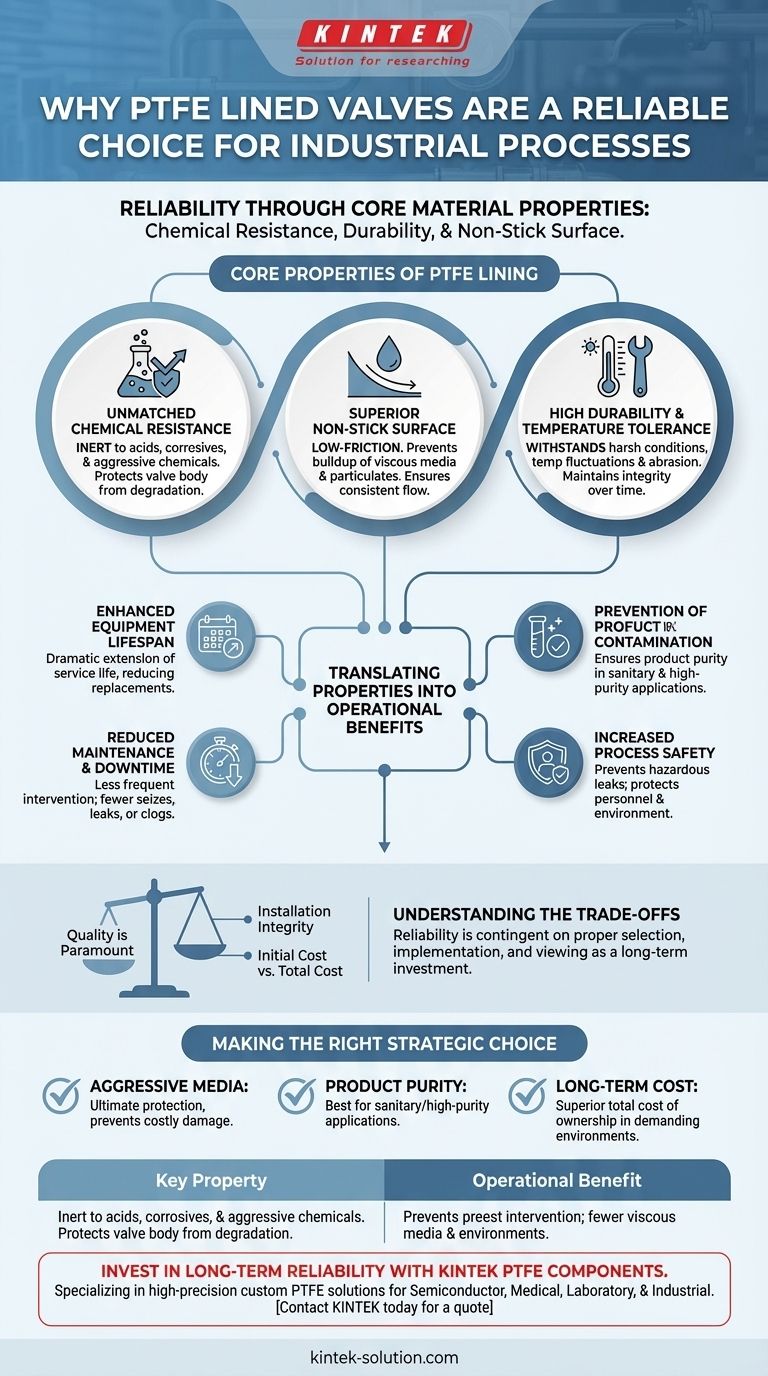

The Core Properties of PTFE Lining

The reliability of these valves stems from three fundamental characteristics of the PTFE material itself. Understanding these properties is key to appreciating their impact on an industrial process.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert polymers known. This makes it exceptionally resistant to a vast range of acids, corrosive agents, and other aggressive chemicals.

This property ensures the valve's structural body is completely isolated from the process fluid, preventing the corrosion that would degrade a standard valve. It is why PTFE is essential in harsh chemical processing and etching applications.

Superior Non-Stick Surface

The surface of PTFE is extremely low-friction and non-stick. Process media, especially those that are viscous or contain particulates, do not adhere to the lining.

This prevents material buildup, which can otherwise impede flow, compromise valve operation, or contaminate subsequent batches. It ensures consistent performance with minimal need for cleaning.

High Durability and Temperature Tolerance

PTFE linings maintain their integrity under harsh industrial conditions, including significant temperature fluctuations and abrasion.

This robustness translates directly to a longer service life. The lining withstands the demanding cycles of processes like drying, curing, and bonding without degrading, ensuring the valve remains functional for an extended period.

Translating Properties into Operational Benefits

The material science of PTFE delivers tangible, real-world advantages that improve efficiency, safety, and an organization's bottom line.

Enhanced Equipment Lifespan

By shielding the valve's core components from the process media, the PTFE lining dramatically extends the equipment's service life. This turns the valve into a long-term, reliable asset rather than a frequently replaced component.

Reduced Maintenance and Downtime

The combination of durability and a non-stick surface means less frequent need for intervention. Valves are less likely to seize, leak, or become clogged, which significantly reduces costly maintenance cycles and unscheduled production downtime.

Prevention of Contamination

For industries like pharmaceuticals, food and beverage, or electronics, product purity is non-negotiable. PTFE's inert nature means it will not leach chemicals into the process fluid, making it an ideal choice for sanitary or high-purity liquid transfer.

Increased Process Safety

High-quality PTFE linings and packings are critical for preventing leaks of hazardous or corrosive materials. This containment is essential for protecting personnel, the surrounding environment, and ensuring regulatory compliance.

Understanding the Trade-offs

While highly effective, a PTFE lined valve's reliability is contingent on proper selection and implementation.

Quality is Paramount

The performance benefits are entirely dependent on the quality of the PTFE material and its application to the valve body. A poorly applied or low-grade lining can fail, exposing the valve to the very media it was meant to be protected from.

Installation Integrity

The integrity of the lining is crucial. Careless handling or installation can scratch or damage the PTFE surface, creating a weak point for chemical attack and premature failure.

Initial Cost vs. Total Cost

PTFE lined valves often have a higher initial purchase price than unlined alternatives. This should be viewed as an investment, as the cost is typically recouped over time through drastically lower maintenance expenses and extended operational life.

Making the Right Choice for Your Goal

Selecting a PTFE lined valve is a strategic decision to enhance process stability.

- If your primary focus is handling aggressive or corrosive media: A PTFE lined valve offers the ultimate protection for your equipment, preventing costly damage and ensuring system integrity.

- If your primary focus is ensuring product purity: The inert, non-stick surface is the best choice for sanitary or high-purity applications where preventing contamination is critical.

- If your primary focus is minimizing long-term operating costs: The durability and low-maintenance design provide a superior total cost of ownership compared to standard valves in demanding environments.

Ultimately, choosing a PTFE lined valve is an investment in the long-term reliability and efficiency of your entire industrial process.

Summary Table:

| Key Property | Operational Benefit |

|---|---|

| Unmatched Chemical Resistance | Protects valve from corrosion, ensuring system integrity. |

| Superior Non-Stick Surface | Prevents material buildup, reduces clogging and contamination. |

| High Durability & Temperature Tolerance | Extends service life and minimizes maintenance downtime. |

Invest in the long-term reliability of your process with KINTEK PTFE components.

PTFE lined valves are a strategic investment to enhance safety, ensure product purity, and minimize your total cost of ownership. At KINTEK, we specialize in manufacturing high-precision PTFE components—including custom seals, liners, labware, and valves—for the semiconductor, medical, laboratory, and industrial sectors.

Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a solution perfectly tailored to handle your aggressive media and demanding environments.

Contact KINTEK today to discuss your specific application and receive a quote for a reliable, long-lasting PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries