The ideal application for a PTFE gasket is any sealing situation that demands extreme chemical resistance and high purity. Polytetrafluoroethylene (PTFE) excels in severe service environments involving aggressive media such as caustic chemicals, acids, solvents, and steam. This makes it a cornerstone material in industries ranging from chemical processing and pharmaceuticals to food manufacturing.

The decision to use a PTFE gasket hinges on its unmatched chemical inertness and high-purity characteristics, not its mechanical strength. While it solves critical challenges related to corrosion and contamination, it introduces potential issues like "cold flow," which must be properly managed.

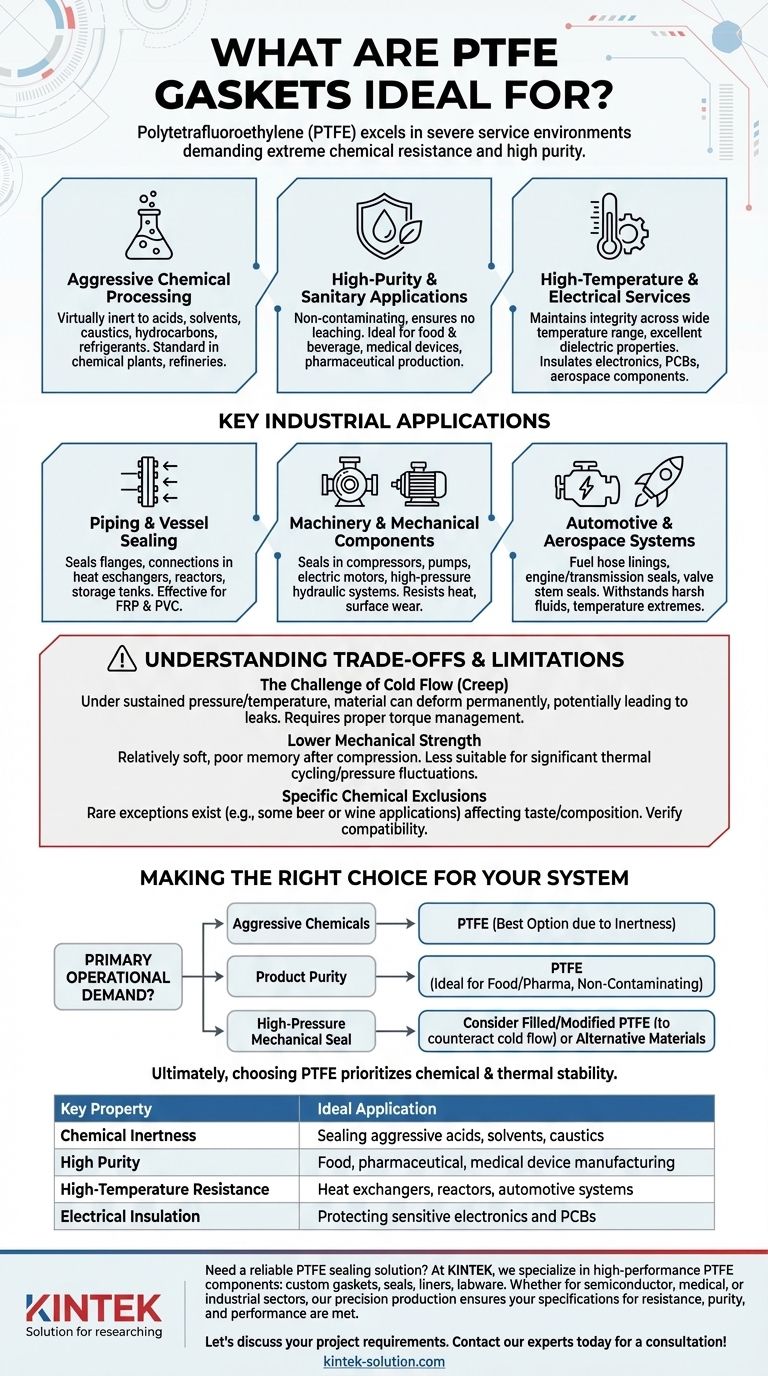

Core Environments Where PTFE Excels

PTFE's unique molecular structure gives it properties that make it the default choice for specific, demanding environments.

Aggressive Chemical Processing

A PTFE gasket is virtually inert to most chemicals. This makes it essential for applications involving highly corrosive substances.

It provides a reliable seal when exposed to aggressive media, including acids, solvents, caustics, hydrocarbons, and refrigerants. This is why it's a standard component in chemical plants, refineries, and petrochemical facilities.

High-Purity and Sanitary Applications

Because PTFE is a non-contaminating material, it is exceptionally well-suited for industries with strict purity standards.

It is frequently specified for food and beverage manufacturing, medical device components, and pharmaceutical production. The material ensures that no impurities from the gasket leach into the product stream.

High-Temperature and Electrical Services

PTFE maintains its integrity across a wide temperature range, making it a frequent replacement for materials like polyethylene in high-heat applications.

Its excellent dielectric properties also make it a valuable insulator for electronic components, such as protecting printed circuit boards and other sensitive electronics in aerospace and computing.

Key Industrial Applications

The properties of PTFE translate directly into its use across a wide variety of industrial equipment and systems.

Piping and Vessel Sealing

PTFE is a top choice for sealing flanges and connections in complex fluid handling systems.

Applications include seals for heat exchangers, distillation towers, reactors, and storage tanks. It is particularly effective for sealing plastic flanges, such as those made from Fibreglass Reinforced Plastic (FRP) or PVC.

Machinery and Mechanical Components

The material's resistance to heat and surface wear makes it suitable for dynamic and critical machine parts.

PTFE is used for seals and gaskets in compressors, pumps, electric motors, and high-pressure hydraulic systems.

Automotive and Aerospace Systems

In these sectors, components must withstand harsh fluids and temperature extremes.

Common uses include fuel hose linings, engine and transmission seals, and valve stem seals. Its combination of chemical resistance and heat tolerance ensures reliability in these critical systems.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Understanding its limitations is critical for proper application.

The Challenge of Cold Flow (Creep)

The most significant drawback of pure PTFE is cold flow, or creep. Under sustained pressure and temperature, the material can deform permanently.

This deformation can cause the sealing pressure on a flange to decrease over time, potentially leading to leaks. This is why proper installation torque and potential re-torquing are critical.

Lower Mechanical Strength

Compared to metallic or many elastomeric gaskets, pure PTFE is a relatively soft material.

It has poor "memory" and is less able to recover its shape after compression. This makes it less suitable for applications with significant thermal cycling or pressure fluctuations where a more resilient seal is required.

Specific Chemical Exclusions

While resistant to most chemicals, there are rare exceptions.

Some sources note that standard PTFE may not be suitable for specific applications, such as those involving beer or wine, where taste or composition could be affected. Always verify compatibility with your specific process media.

Making the Right Choice for Your System

To determine if a PTFE gasket is the correct choice, match its unique properties to your primary operational demand.

- If your primary focus is containing aggressive chemicals: PTFE is almost certainly your best option due to its near-universal chemical inertness.

- If your primary focus is product purity: PTFE is ideal for food, medical, or pharmaceutical applications where preventing contamination is non-negotiable.

- If your primary focus is a high-pressure mechanical seal: You must consider a filled or modified PTFE gasket to counteract its natural tendency for cold flow, or explore alternative materials entirely.

Ultimately, choosing PTFE is a strategic decision to prioritize chemical and thermal stability above all else.

Summary Table:

| Key Property | Ideal Application |

|---|---|

| Chemical Inertness | Sealing aggressive acids, solvents, and caustics |

| High Purity | Food, pharmaceutical, and medical device manufacturing |

| High-Temperature Resistance | Heat exchangers, reactors, and automotive systems |

| Electrical Insulation | Protecting sensitive electronics and PCBs |

Need a reliable PTFE sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a seal that meets your exact specifications for chemical resistance, purity, and performance.

Let's discuss your project requirements. Contact our experts today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is PTFE used for in bearing bushings? To enable self-lubrication in extreme environments.

- Are PTFE valves non-toxic, and why is this important? Ensure Product Purity and Safety

- How can PTFE bellows be customized for different applications? Tailor Flexibility, Pressure Rating, and Purity

- How do PTFE rotary shaft seals compare to traditional rubber seals? Superior Performance for Extreme Conditions

- How should Teflon O-rings be maintained? A Proactive Guide to Prevent Seal Failure

- How do PTFE lined check valves integrate with modern water pump systems? Boost Efficiency and Protect Your System

- How have recent innovations improved Teflon gland packing technology? From Passive Seals to Smart Systems

- What are the key properties of PTFE industrial coating? Discover Unmatched Performance for Demanding Industries