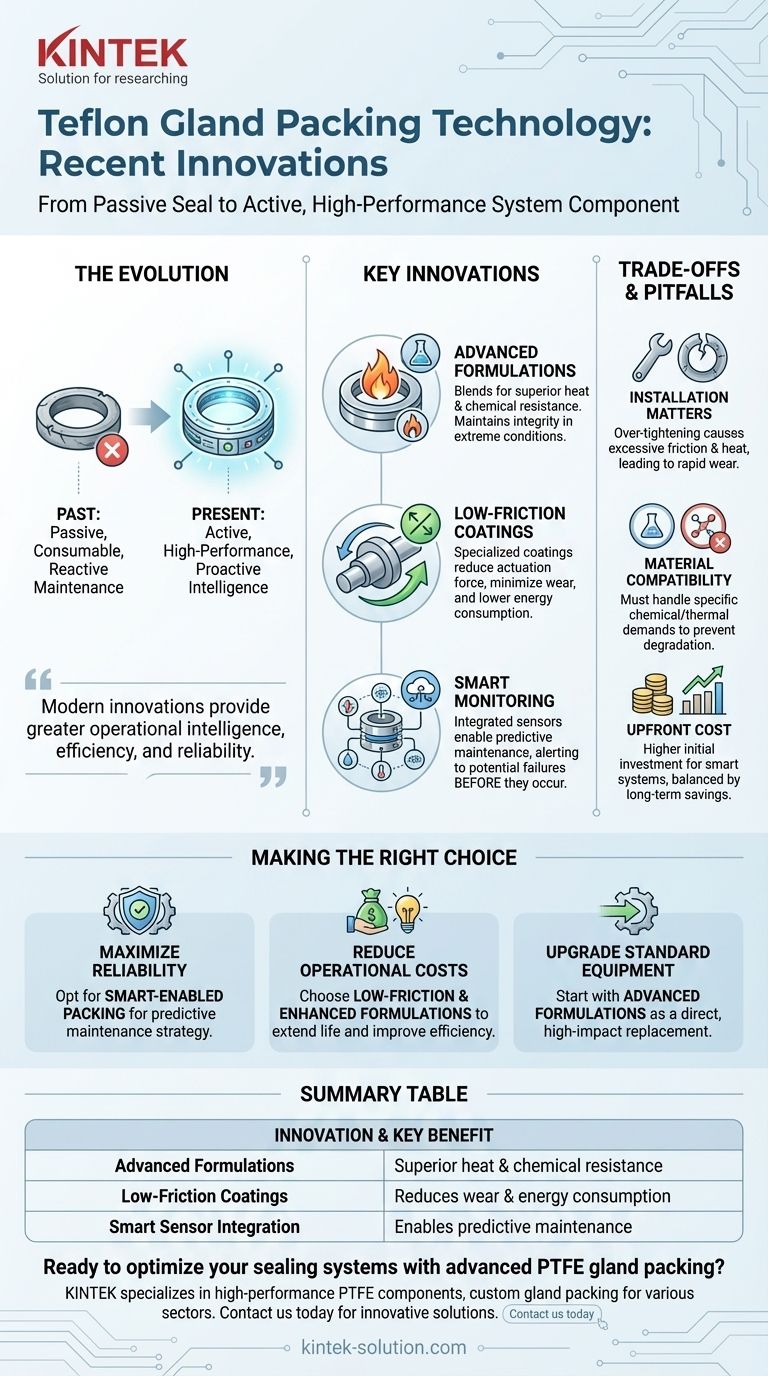

In recent years, Teflon gland packing has evolved significantly beyond a simple sealing component. The most impactful innovations include the development of enhanced performance formulations with superior heat and chemical resistance, the application of advanced low-friction coatings, and the integration of smart sensors for predictive maintenance.

The core shift in Teflon gland packing is its transformation from a passive, consumable part into an active, high-performance system component. Modern innovations are not just about better materials, but about providing greater operational intelligence, efficiency, and reliability.

The Evolution from Passive Seal to Active Component

Historically, gland packing was a straightforward wear item requiring reactive maintenance. Today's innovations are proactive, designed to extend life, improve efficiency, and provide critical operational data.

Beyond Basic PTFE: Advanced Formulations

The foundation of modern packing is no longer just pure PTFE resin. Manufacturers now create enhanced formulations by blending PTFE with other materials.

This results in packing that offers vastly improved resistance to aggressive chemicals and extreme temperatures, maintaining sealing integrity in applications where basic Teflon would quickly degrade.

The Critical Role of Low-Friction Coatings

A key source of wear on both packing and equipment is friction. Innovations now include specialized low-friction surface coatings applied during manufacturing.

These coatings dramatically reduce the force required to actuate valves or rotate shafts, which minimizes equipment wear, lowers energy consumption, and extends the packing's service life.

The Leap to Smart Monitoring

The most forward-looking innovation is the integration of sensors directly with the gland packing assembly.

These sensors monitor key indicators like leakage, temperature, and friction in real-time. This data feeds into a predictive maintenance system, alerting operators to potential failures before they occur and transforming maintenance from a reactive task to a planned activity.

Understanding the Trade-offs and Common Pitfalls

While advanced, these technologies are not a cure-all. Their effectiveness is still governed by fundamental principles of installation and application.

Technology Cannot Replace Proper Installation

Even the most advanced, low-friction packing will fail prematurely if installed incorrectly. Over-tightening is a common mistake that causes excessive friction and heat buildup, leading to rapid wear and potential equipment damage.

Material Compatibility Remains Paramount

Enhanced formulations have expanded the operational range of Teflon packing, but they are not universally compatible. Selecting a packing material that cannot handle the specific chemical or thermal demands of the application will inevitably lead to degradation and seal failure.

The Upfront Cost of Smart Systems

Integrating sensor technology for predictive maintenance requires a higher initial investment compared to traditional packing. This cost must be weighed against the long-term savings generated by reduced downtime, lower labor costs, and prevention of catastrophic failures.

Making the Right Choice for Your Goal

Selecting the right packing technology depends entirely on your operational priorities.

- If your primary focus is maximizing reliability in critical systems: Opt for smart-enabled packing with integrated sensors to enable a predictive maintenance strategy.

- If your primary focus is reducing long-term operational costs: Choose packing with enhanced formulations and low-friction coatings to extend service life and improve energy efficiency.

- If your primary focus is upgrading standard equipment with minimal changes: Start with advanced formulation packing as a direct, high-impact replacement that offers better performance without system modification.

Ultimately, modern Teflon packing innovations allow you to treat sealing not as a maintenance chore, but as a strategic element of system optimization.

Summary Table:

| Innovation | Key Benefit |

|---|---|

| Advanced Formulations | Superior heat & chemical resistance |

| Low-Friction Coatings | Reduces wear & energy consumption |

| Smart Sensor Integration | Enables predictive maintenance |

Ready to optimize your sealing systems with advanced PTFE gland packing?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gland packing, for the semiconductor, medical, laboratory, and industrial sectors. Whether you need a prototype or a high-volume order, our precision production ensures reliability and efficiency.

Contact us today to discuss how our innovative solutions can enhance your operational intelligence and reduce long-term costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What advantages does carbon-graphite-filled PTFE offer? Enhance Wear Resistance & Thermal Management

- What are some specific applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & Thermal Environments

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- How are PTFE lined butterfly valves assembled with bolts? A Guide to Secure, Leak-Free Installation

- What are the key properties of PTFE that benefit gland packing? Achieve Superior Sealing Performance

- What are the common applications of PTFE sheets? Solve Extreme Chemical, Friction & Temperature Challenges

- Why are PTFE sheets used in the medical industry? For Biocompatibility, Inertness & Low Friction

- How does PTFE's low coefficient of friction affect its machining process? Balancing Clean Cuts with Material Distortion