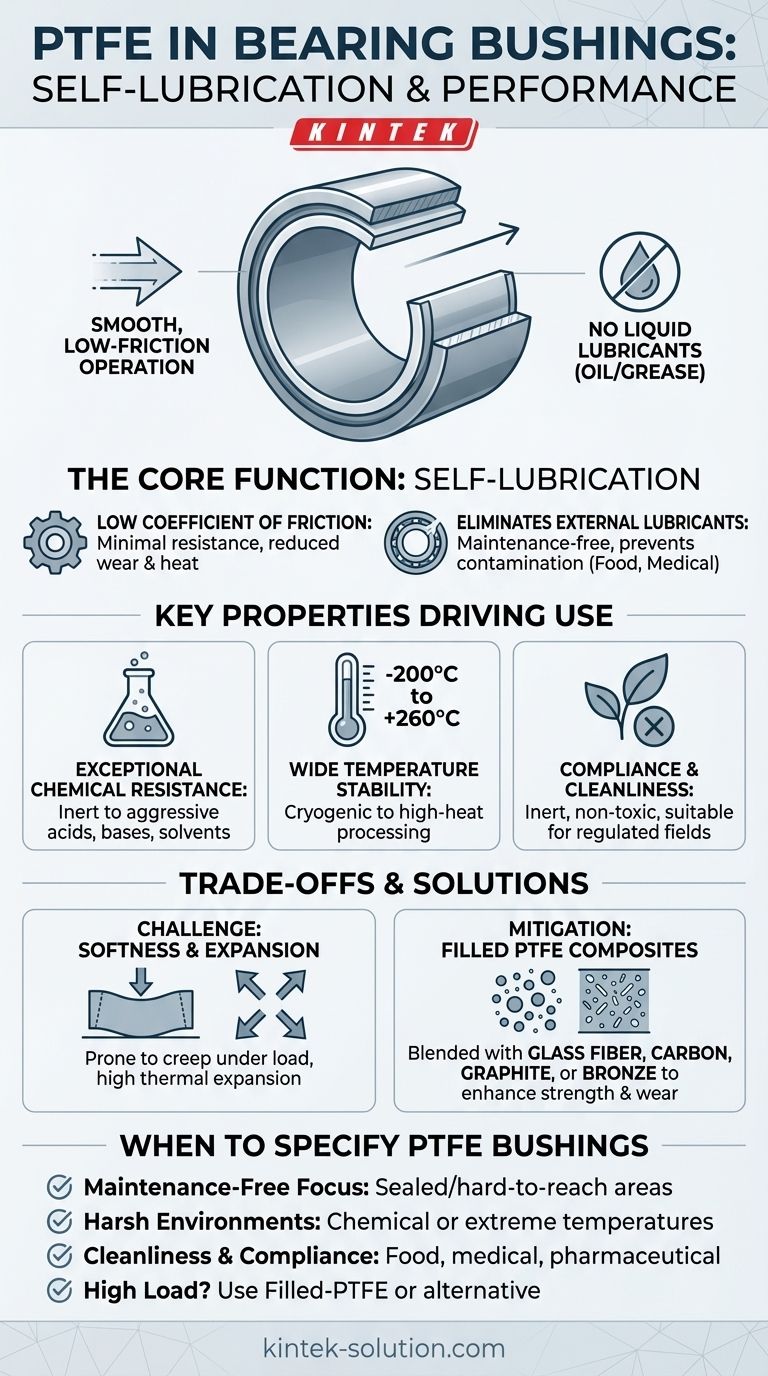

In bearing applications, Polytetrafluoroethylene (PTFE) serves one primary purpose: to create a high-performance, self-lubricating sliding surface. This eliminates the need for traditional liquid lubricants like oil or grease, ensuring smooth, low-friction operation for the moving components.

The core value of PTFE in a bearing is not just its non-stick nature, but its unique combination of low friction, extreme chemical inertness, and a wide operating temperature range. This makes it the definitive material for applications where conventional lubrication is impractical, undesirable, or simply impossible.

The Core Function: Self-Lubrication

PTFE's fundamental role is to act as a solid lubricant. It is either used as a liner within a metal bushing or as the bulk material for the bushing itself.

How PTFE Reduces Friction

The polymer has an exceptionally low coefficient of friction, one of the lowest of any solid material. This inherent slipperiness means that parts can move against each other with minimal resistance.

This reduction in friction directly translates to less wear, lower heat generation, and reduced power consumption for the machine.

Eliminating External Lubricants

The self-lubricating property is critical in many industries. It allows for maintenance-free designs in sealed or hard-to-reach components.

More importantly, it prevents contamination in sensitive applications like food processing, pharmaceutical manufacturing, and medical equipment, where lubricant leakage would be a critical failure.

Key Properties Driving Its Use

Beyond low friction, several other properties make PTFE an ideal choice for specific, challenging environments.

Exceptional Chemical Resistance

PTFE is almost entirely chemically inert. It can withstand exposure to the most aggressive acids, bases, and solvents without degrading.

This makes PTFE bushings essential components in chemical processing equipment and in the oil and gas industry, where they are exposed to harsh substances.

Wide Temperature Stability

PTFE maintains its properties over an enormous temperature range, typically from -200°C to +260°C (-328°F to +500°F).

This allows it to be used in everything from cryogenic applications to high-temperature processing machinery where other polymers would fail.

Compliance and Cleanliness

Because it is inert and non-toxic, certain grades of PTFE comply with strict regulatory standards for food contact and medical use. This makes it a go-to material in these highly regulated fields.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not a universal solution. Its mechanical properties present clear trade-offs that every engineer must consider.

The Challenge of Softness

In its pure form, PTFE is a relatively soft material. It can be prone to "creep" or cold flow, meaning it can deform over time under a constant load. This limits its use in high-load applications.

High Thermal Expansion

PTFE has a high coefficient of thermal expansion compared to metals. Its dimensions will change significantly with temperature fluctuations.

This must be accounted for during the design phase to maintain proper clearances and prevent the bearing from seizing or becoming too loose.

How Engineers Mitigate These Weaknesses

To overcome these mechanical limitations, PTFE is often blended with fillers. Adding materials like glass fiber, carbon, graphite, or bronze creates a composite that enhances strength, reduces thermal expansion, and improves wear resistance while retaining PTFE's core benefits.

When to Specify PTFE Bushings

Choosing the right bearing material depends entirely on the operational goal and environment.

- If your primary focus is maintenance-free operation: PTFE is ideal for sealed-for-life components or hard-to-reach areas where regular lubrication is impractical.

- If your primary focus is harsh environments: Its chemical inertness and wide temperature range make it a default choice for chemical processing, cryogenics, or high-heat machinery.

- If your primary focus is cleanliness and compliance: Its inert nature is essential for food, medical, and pharmaceutical equipment where lubricant contamination is unacceptable.

- If your primary focus is high mechanical load: Pure PTFE is likely unsuitable; you must specify a filled-PTFE composite or explore an alternative bearing technology.

By understanding both its unique advantages and its inherent mechanical limitations, you can leverage PTFE to design highly reliable and efficient systems.

Summary Table:

| Property | Benefit for Bearing Bushings |

|---|---|

| Low Coefficient of Friction | Self-lubricating; eliminates need for external oil/grease. |

| Exceptional Chemical Resistance | Withstands harsh acids, bases, and solvents. |

| Wide Temperature Range (-200°C to +260°C) | Performs in cryogenic to high-heat applications. |

| Compliance & Cleanliness | Ideal for food, medical, and pharmaceutical uses. |

Need a reliable PTFE bushing for a demanding application? KINTEK specializes in manufacturing high-performance PTFE components, including custom bearing bushings, seals, and liners. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering precision parts from prototypes to high-volume orders. Let us help you solve your toughest design challenges with a material that offers maintenance-free operation and extreme environmental resistance. Contact our experts today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support