In any demanding sealing application, the choice between PTFE and traditional rubber is a critical engineering decision. PTFE (polytetrafluoroethylene) rotary shaft seals fundamentally outperform their rubber counterparts in harsh environments due to superior chemical resistance, a significantly wider operating temperature range, and much lower friction. This makes them the definitive choice for high-speed, high-pressure, or chemically aggressive systems where a standard rubber seal would quickly fail.

The choice between PTFE and rubber seals isn't about which material is "better" in a general sense, but which is engineered for a specific operational reality. PTFE is a specialized solution for extreme conditions, while rubber remains a cost-effective standard for less demanding applications.

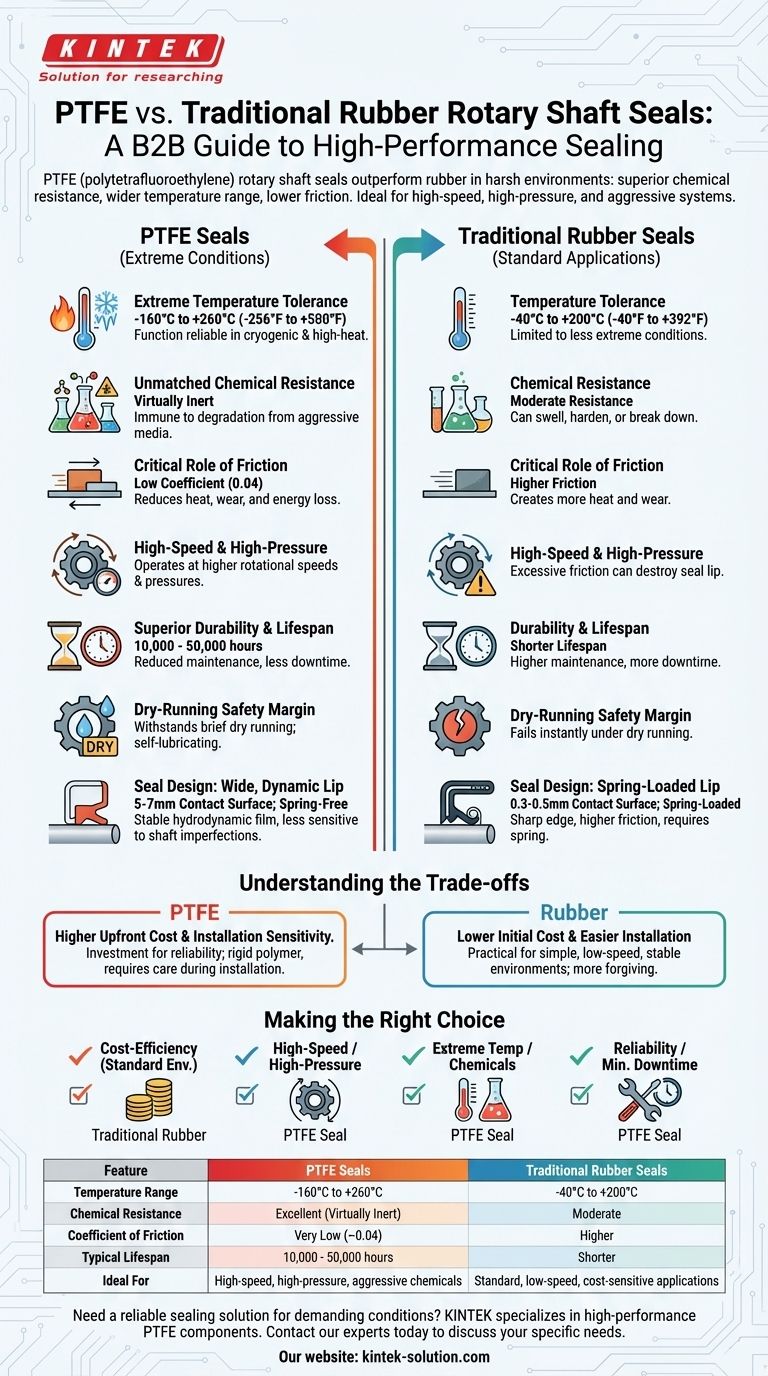

The Core Differences in Material Properties

The performance gap between PTFE and rubber begins at the molecular level. These material differences dictate how each seal behaves under stress.

Extreme Temperature Tolerance

A primary advantage of PTFE is its vast operational temperature range, typically from –160°C to +260°C (–256°F to +500°F).

This allows PTFE seals to function reliably in everything from cryogenic processes to high-heat industrial machinery. In contrast, standard rubber seals have a much narrower range, often limited to –40°C to +200°C (–40°F to +392°F), making them unsuitable for temperature extremes.

Unmatched Chemical Resistance

PTFE is one of the most chemically inert materials used in industry. It is virtually immune to degradation from aggressive chemicals, solvents, and corrosive fluids.

Rubber seals, on the other hand, have only moderate chemical resistance and can swell, harden, or break down when exposed to incompatible media, leading to inevitable leaks and failure.

The Critical Role of Friction

PTFE has an exceptionally low coefficient of friction (as low as 0.04), meaning it is inherently slick. This property is crucial in rotary applications.

Lower friction reduces heat generation at the contact point, minimizes energy loss, and dramatically slows the rate of wear on both the seal and the shaft. Rubber has significantly higher friction, which creates more heat and wear.

How Material Properties Translate to Performance

These fundamental material advantages give PTFE seals a clear performance edge in demanding scenarios, impacting speed, lifespan, and overall system reliability.

High-Speed and High-Pressure Capability

The combination of low friction and high-temperature tolerance allows PTFE seals to operate at much higher rotational speeds and pressures than rubber seals.

Excessive friction in a rubber seal at high speeds would generate enough heat to destroy the seal lip, a problem that PTFE's properties effectively eliminate.

Superior Durability and Lifespan

PTFE seals exhibit excellent wear resistance and resistance to aging. Their operational lifespan is often cited between 10,000 to 50,000 hours, far exceeding that of a typical rubber seal in a comparable high-stress application.

This longevity translates directly into reduced maintenance, less downtime, and lower long-term operational costs.

Dry-Running Safety Margin

Because PTFE is self-lubricating, it can withstand brief periods of dry running in an emergency, such as a temporary loss of system lubrication.

A rubber seal would fail almost instantly under such conditions, potentially causing catastrophic damage to the shaft and surrounding components.

A Fundamentally Different Sealing Design

The material differences also enable distinct design philosophies that further separate the two seal types.

Rubber Seals: The Spring-Loaded Lip

Traditional rubber oil seals use a sharp, flexible lip with a very narrow contact surface of just 0.3-0.5mm. A garter spring is required to apply constant pressure, forcing this sharp edge against the shaft to create a seal.

PTFE Seals: The Wide, Dynamic Lip

PTFE seals employ a spring-free design with a wide, flat lip that has a contact surface of 5-7mm. This design creates a more stable hydrodynamic film, allowing a thin layer of lubricant to pass under the lip.

This wide contact patch makes the seal less sensitive to shaft imperfections or eccentricity (runout), ensuring a more consistent and reliable seal over time.

Understanding the Trade-offs

While PTFE offers superior performance, it is not the default choice for every situation. Objectivity requires acknowledging its specific limitations.

Cost Considerations

PTFE seals are more expensive upfront than their rubber counterparts. The decision to use them must be justified by the application's demands. Their higher cost is an investment in reliability and longevity, preventing more expensive failures down the line.

Installation Sensitivity

PTFE is a rigid polymer, not an elastic rubber. This means PTFE seals are less forgiving during installation. Care must be taken to avoid scratching or nicking the seal lip, as any damage can create a permanent leak path.

Application Suitability

For simple, low-speed, and non-aggressive environments with stable temperatures, a standard rubber seal is often the most practical and cost-effective solution. Using a high-performance PTFE seal in such an application would be unnecessary over-engineering.

Making the Right Choice for Your Application

Selecting the correct seal requires matching its engineered capabilities to the operational demands of the system.

- If your primary focus is cost-efficiency in a standard environment: A traditional rubber seal is likely the most practical and economical choice.

- If your application involves high rotational speeds or high pressure: The low-friction and durable design of a PTFE seal is essential to prevent premature wear and failure.

- If you are dealing with extreme temperatures or aggressive chemicals: PTFE is the only viable option, as its material properties are specifically designed to withstand these conditions.

- If reliability and minimizing downtime are your top priorities: The extended lifespan and dry-running capabilities of PTFE seals justify the higher initial investment.

Ultimately, choosing the right seal is about understanding the environment it must survive in and selecting the material engineered to thrive there.

Summary Table:

| Feature | PTFE Seals | Traditional Rubber Seals |

|---|---|---|

| Temperature Range | -160°C to +260°C | -40°C to +200°C |

| Chemical Resistance | Excellent (Virtually Inert) | Moderate |

| Coefficient of Friction | Very Low (~0.04) | Higher |

| Typical Lifespan | 10,000 - 50,000 hours | Shorter |

| Ideal For | High-speed, high-pressure, aggressive chemicals | Standard, low-speed, cost-sensitive applications |

Need a reliable sealing solution for demanding conditions?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services ensure you get a seal engineered to thrive in your specific environment, from prototype to high-volume production.

Contact our experts today to discuss how our PTFE seals can enhance your system's reliability, reduce downtime, and lower your long-term operational costs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability