To put it simply, PTFE lined check valves integrate seamlessly with modern water pump systems by acting as a critical safeguard that enhances both performance and longevity. They achieve this by preventing damaging backflow, minimizing energy consumption due to their low fluid resistance, and protecting the system from corrosion.

The core takeaway is that a PTFE lined check valve is not just a component, but a strategic upgrade. It directly addresses the primary failure points in water systems—backflow, corrosion, and pressure loss—making the entire pump operation more efficient, reliable, and cost-effective.

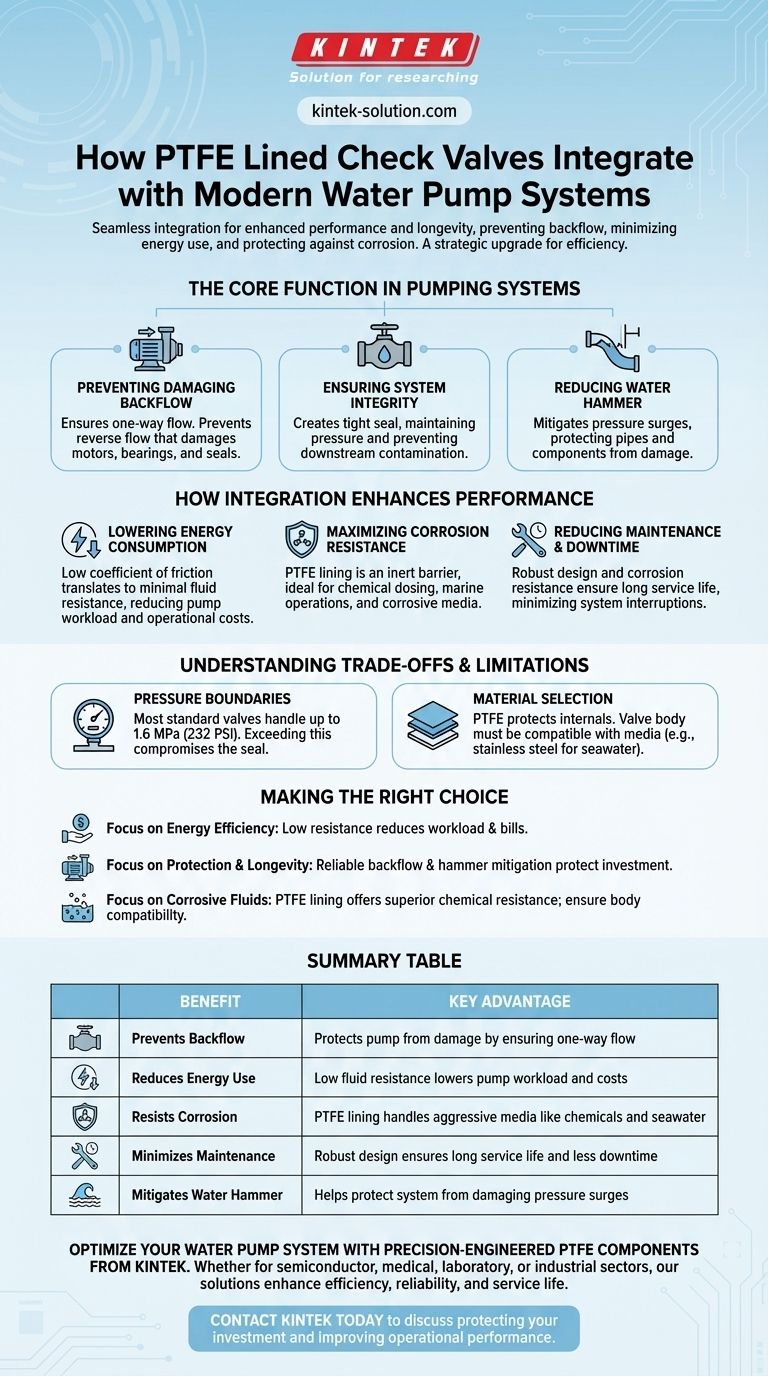

The Core Function in Pumping Systems

A check valve's role is fundamentally about control. In a modern water pump system, where precision and reliability are paramount, a PTFE lined valve provides this control with exceptional durability.

Preventing Damaging Backflow

The most crucial function of any check valve is to permit fluid to flow in only one direction.

When a pump shuts off, the pressure differential can cause water to flow backward, a phenomenon known as backflow. This reversal can spin the pump impeller backward, potentially causing significant damage to the motor, bearings, and seals.

Ensuring System Integrity

An effective check valve must create a tight seal to prevent leakage when closed.

This capability is essential for maintaining system pressure when the pump is not active. It also prevents the contamination of the source by ensuring no fluid from the downstream system can seep back.

Reducing Water Hammer

Modern systems are susceptible to pressure surges, or water hammer, which can damage pipes and components.

PTFE lined check valves help mitigate these damaging effects, providing a layer of protection that contributes to the overall stability and lifespan of the system.

How Integration Enhances Modern Pump Performance

Choosing a PTFE lined check valve goes beyond basic backflow prevention. The unique properties of PTFE (Polytetrafluoroethylene) provide distinct advantages that directly boost the efficiency of modern pumps.

Lowering Energy Consumption

Every component in a fluid system introduces some level of resistance. PTFE is known for its extremely low coefficient of friction.

This translates to minimal fluid resistance as water passes through the valve, meaning the pump doesn't have to work as hard to move the same volume of water. The result is lower energy usage and reduced operational costs over time.

Maximizing Chemical and Corrosion Resistance

The PTFE lining creates an inert barrier between the system fluid and the valve's internal components.

This makes these valves exceptionally resistant to corrosion and chemical attack. They are ideal for applications beyond simple water transport, including chemical dosing systems, marine operations using seawater, and other industrial processes involving corrosive media.

Reducing Maintenance and Downtime

The combination of corrosion resistance and robust design gives these valves a long service life.

Their reliability and minimal maintenance requirements mean less system downtime, which is a critical factor in any commercial or industrial operation.

Understanding the Trade-offs and Limitations

While highly effective, PTFE lined check valves are not a universal solution. Understanding their operational boundaries is key to successful integration.

Pressure Boundaries

These valves are designed for specific pressure ranges.

Most standard PTFE lined check valves can handle pressures up to 1.6 MPa (or 232 PSI). Exceeding this limit can compromise the seal and lead to valve failure.

Material Selection for Aggressive Media

The PTFE lining protects the internals, but the valve body itself must also be compatible with the fluid.

For highly corrosive substances like seawater, a standard cast iron body may not suffice. In these cases, a valve with a stainless steel body and more robust alloy seals is necessary to ensure long-term integrity.

Making the Right Choice for Your System

Selecting the correct valve requires aligning its features with your primary operational goal.

- If your primary focus is energy efficiency: The low fluid resistance of a PTFE lined valve directly reduces pump workload and lowers energy bills.

- If your primary focus is system protection and longevity: The valve's reliable backflow prevention and water hammer mitigation are essential for protecting your pump and pipeline investment.

- If your primary focus is handling corrosive fluids: The PTFE lining provides superior chemical resistance, but you must also ensure the valve's body material is appropriate for the specific medium.

Ultimately, integrating the right PTFE lined check valve is a proactive measure to optimize the performance and resilience of your entire water pump system.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Prevents Backflow | Protects pump from damage by ensuring one-way flow |

| Reduces Energy Use | Low fluid resistance lowers pump workload and costs |

| Resists Corrosion | PTFE lining handles aggressive media like chemicals and seawater |

| Minimizes Maintenance | Robust design ensures long service life and less downtime |

| Mitigates Water Hammer | Helps protect system from damaging pressure surges |

Optimize your water pump system with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our PTFE lined check valves and custom fabrications are designed to enhance your system's efficiency, reliability, and service life. We specialize in creating solutions—from prototypes to high-volume orders—that meet the exacting demands of specialized industries.

Contact KINTEK today to discuss how our PTFE components can protect your investment and improve your operational performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the additional characteristics of PTFE rods? Unlock Superior Performance in Harsh Environments

- What temperature range can PTFE seals and rings operate within? Withstand -200°C to +260°C Extremes

- What are the key advantages of PTFE shaft seals? Superior Performance in Extreme Conditions

- What are the advantages of using PTFE bushes? Low-Friction, Chemical-Resistant Performance

- What temperature range can PTFE rods withstand? From -200°C to +260°C for Extreme Versatility

- How does a PTFE lined ball valve work? A Guide to Corrosion-Free Flow Control

- What types of chemicals can ePTFE gaskets withstand? Seal Aggressive Media with Near-Universal Resistance

- What non-standard options are available for PTFE slide bearings? Customize for Temperature, Load, and Movement