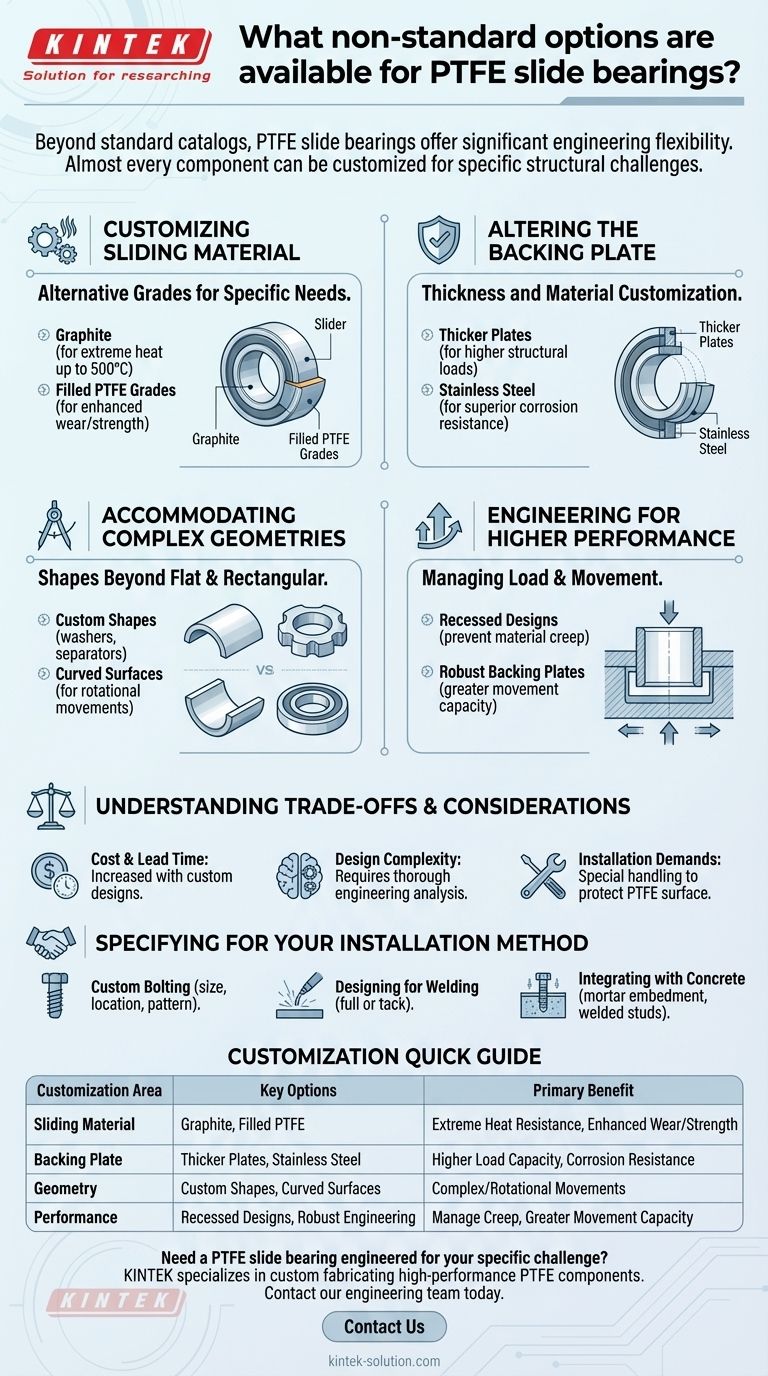

Beyond the standard catalog, PTFE slide bearings offer a wide range of non-standard options that allow for significant engineering flexibility. The most common customizations involve specifying alternative PTFE grades, using different backing plate materials and thicknesses, designing unique shapes, and engineering for higher loads or greater movements.

The core principle to understand is that a "standard" PTFE bearing is simply a pre-engineered solution for a common problem. Nearly every component—from the sliding material to the steel plate—can be customized to solve specific and demanding structural challenges related to temperature, load, movement, or geometry.

Defining the "Standard" Bearing

To understand non-standard options, we must first define the baseline. A standard configuration is designed to meet the most frequent industry needs efficiently and cost-effectively.

The Typical Configuration

A common off-the-shelf slide bearing consists of 3mm thick PTFE bonded directly to an 8mm thick carbon steel backing plate. This design is generally suitable for service temperatures up to 130°C.

High-Temperature Standards

For higher heat environments, two other configurations are considered standard: 5mm thick PTFE recessed into a backing plate for temperatures up to 200°C, and a 5mm thick graphite insert for extreme temperatures between 400-500°C.

Key Areas for Customization

When standard options are insufficient, you can modify the bearing's design in several key ways to meet the specific demands of your project.

Modifying the Sliding Material

While pure PTFE is common, alternative grades can be specified. For extreme heat applications, graphite is a proven alternative. Other filled PTFE grades can also be used to enhance properties like compressive strength or wear resistance.

Altering the Backing Plate

The backing plate can be customized in both thickness and material. Thicker plates are specified to handle higher structural loads, while using materials like stainless steel instead of carbon steel provides superior corrosion resistance.

Accommodating Complex Geometries

Bearings are not limited to flat, rectangular shapes. They can be fabricated into custom shapes or designed with curved surfaces to permit rotational movements that a standard flat bearing cannot accommodate. They can also serve as thermal breaks, washers, or separators.

Engineering for Higher Performance

Beyond material changes, bearings can be engineered for higher loadings or greater movement capacity. This often involves a combination of thicker PTFE, recessed designs to prevent material creep, and more robust backing plates.

Understanding the Trade-offs

Customization provides tailored solutions but also introduces important considerations that are not present with standard, off-the-shelf components.

Cost and Lead Time

Any deviation from a standard design will almost certainly increase both the cost per unit and the manufacturing lead time. This must be factored into project budgets and timelines.

Design Complexity

Specifying a non-standard bearing requires a more thorough engineering analysis to ensure it meets all performance requirements safely. This places a greater responsibility on the design team.

Installation Demands

Custom bearings may require special handling during installation. The PTFE surface is vulnerable and must be protected from weld spatter, paint, and construction debris to ensure its low-friction properties are not compromised.

Specifying for Your Installation Method

The bearing's design must be compatible with its intended installation method, which often requires customization of the backing plate.

Custom Bolting Configurations

While bolting is a common installation method, the size, location, and pattern of bolt holes can be customized to match the specific requirements of the supporting structure.

Designing for Welding

If the bearing will be permanently attached by full welding or tack welding, the backing plate material and thickness must be suitable for the specified welding procedure.

Integrating with Concrete

For applications involving concrete, the bearing can be designed for mortar embedment. This typically involves specifying a plate with welded studs or other features to ensure a robust mechanical lock into the structure.

Making the Right Choice for Your Goal

By understanding the available variables, you can specify a bearing that moves beyond a generic component and becomes an engineered solution.

- If your primary focus is extreme temperature: Look into recessed graphite or specialized high-temperature PTFE grades.

- If your primary focus is complex movement or rotation: Specify bearings with curved surfaces or custom shapes that match your structural geometry.

- If your primary focus is accommodating very high loads: Focus on specifying thicker backing plates and recessed PTFE to manage material creep.

- If your primary focus is seamless installation: Ensure the backing plate is explicitly designed for your chosen method, whether it's a unique bolt pattern, welding, or mortar embedment.

By thinking of a slide bearing as a customizable system, you can engineer a precise solution for your unique structural challenge.

Summary Table:

| Customization Area | Key Options | Primary Benefit |

|---|---|---|

| Sliding Material | Graphite, Filled PTFE Grades | Extreme Heat Resistance, Enhanced Wear/Strength |

| Backing Plate | Thicker Plates, Stainless Steel | Higher Load Capacity, Corrosion Resistance |

| Geometry | Custom Shapes, Curved Surfaces | Complex/Rotational Movements |

| Performance | Recessed Designs, Robust Engineering | Manage Creep, Greater Movement Capacity |

Need a PTFE slide bearing engineered for your specific challenge?

KINTEK specializes in custom fabricating high-performance PTFE components, including slide bearings, for the semiconductor, medical, laboratory, and industrial sectors. We can tailor the sliding material, backing plate, and geometry to solve your unique problems with temperature, load, movement, or installation.

Contact our engineering team today to discuss your project requirements—from prototype to high-volume production.

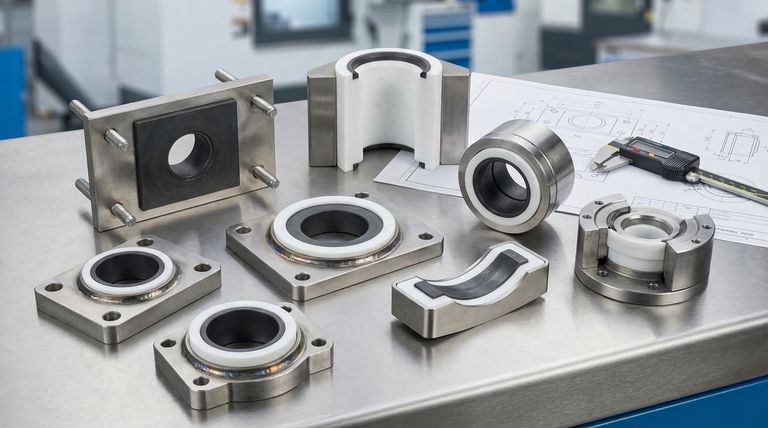

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability