The primary advantages of PTFE bushes stem from their unique combination of an extremely low-friction surface and resistance to harsh environments. These components are self-lubricating, meaning they operate smoothly without external grease or oil, and they exhibit unparalleled resistance to nearly all chemicals and a very wide range of temperatures.

The core reason to choose a PTFE bush is not for mechanical strength, but for its unique problem-solving capabilities in specific environments. It excels where you need maintenance-free, clean operation, or where the component will be exposed to extreme temperatures, corrosive chemicals, or sensitive electrical applications.

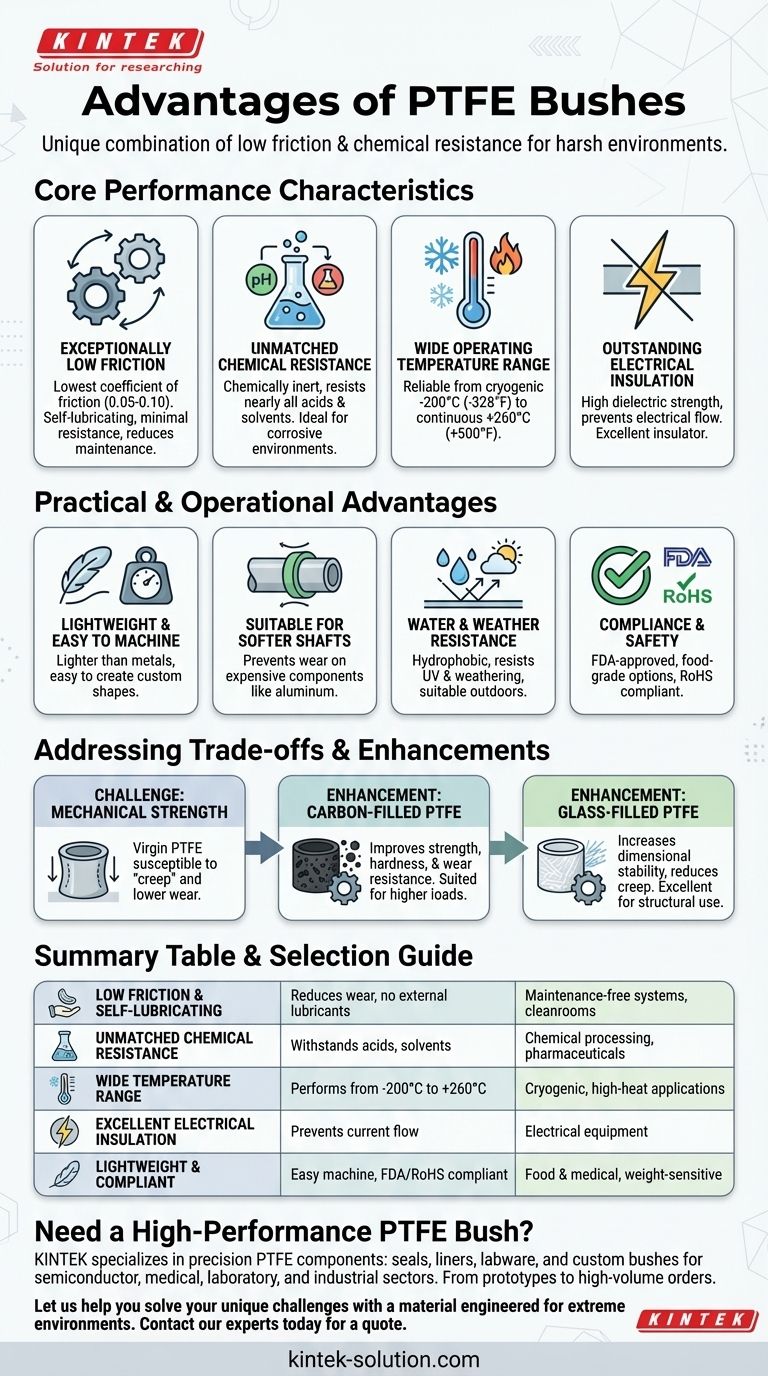

The Core Performance Characteristics of PTFE

Polytetrafluoroethylene (PTFE) is a fluoropolymer with a distinct set of properties that make it a superior choice for specialized bushing applications.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, typically ranging from 0.05 to 0.10.

This creates a self-lubricating surface. Moving parts operate with minimal resistance, reducing the need for external lubricants and the maintenance they require.

Unmatched Chemical Resistance

PTFE is chemically inert and resistant to nearly all industrial chemicals, acids, and solvents.

This makes it an essential material for bushings used in chemical processing, pharmaceuticals, and other corrosive environments where metals would quickly degrade.

Wide Operating Temperature Range

PTFE maintains its properties across an exceptionally broad temperature spectrum, from cryogenic lows of -200°C (-328°F) up to continuous service temperatures of +260°C (+500°F).

This thermal stability allows PTFE bushes to perform reliably in applications involving extreme heat or cold.

Outstanding Electrical Insulation

PTFE possesses very high dielectric strength and electrical resistance, making it an excellent electrical insulator. This property is critical for applications where the bushing must prevent the flow of electricity.

Practical and Operational Advantages

Beyond its core material science, PTFE offers several benefits that simplify design, installation, and compliance.

Lightweight and Easy to Machine

PTFE is significantly lighter than metal alternatives like bronze or steel, which can be advantageous in weight-sensitive designs. It is also a soft material that is easy to machine into custom shapes and sizes.

Suitability for Softer Shafts

Because PTFE is a relatively soft material, it is less likely to cause wear on softer shaft materials, such as aluminum or certain stainless steels. This protects more expensive components from damage.

Water and Weather Resistance

PTFE is hydrophobic, meaning it repels water and resists moisture absorption. It also exhibits excellent resistance to UV radiation and weathering, making it suitable for outdoor applications.

Compliance and Safety

Many grades of PTFE are FDA-approved and food-grade, making them safe for use in food processing and medical equipment. They also often comply with RoHS standards for environmental safety.

Understanding the Trade-offs and Enhancements

While its advantages are significant, it is crucial to understand the limitations of standard PTFE and how they can be addressed.

The Challenge of Mechanical Strength

The primary drawback of standard (virgin) PTFE is its relatively low mechanical strength. It is susceptible to "creep," or deformation under a sustained load, and has lower wear resistance compared to many metals.

Enhancement with Fillers: Carbon-Filled PTFE

Adding carbon as a filler significantly improves mechanical strength, hardness, and wear resistance. Carbon-filled PTFE bushes are better suited for moderate-to-high loads and applications requiring high thermal conductivity.

Enhancement with Fillers: Glass-Filled PTFE

Adding glass fibers dramatically increases dimensional stability and reduces creep. Glass-filled PTFE offers excellent chemical resistance and is often used in structural applications where maintaining shape under load is critical.

Selecting the Right PTFE Bush for Your Application

Choosing the correct type of PTFE is essential for performance. Your decision should be guided by the primary demands of your application.

- If your primary focus is pure chemical resistance or food safety: Standard (virgin) PTFE is the ideal choice for its inertness and compliance.

- If your primary focus is wear resistance and higher loads: Carbon-filled PTFE provides the necessary mechanical strength and durability.

- If your primary focus is dimensional stability under load: Glass-filled PTFE offers the best resistance to creep and deformation.

- If your primary focus is a clean, low-friction, maintenance-free system: Any type of PTFE will deliver self-lubricating benefits over traditional bushings.

Ultimately, leveraging PTFE successfully means applying its unique strengths to solve challenges that other materials simply cannot address.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Low Friction & Self-Lubricating | Reduces wear, eliminates external lubricants | Maintenance-free systems, cleanrooms |

| Unmatched Chemical Resistance | Withstands acids, solvents, and corrosive agents | Chemical processing, pharmaceuticals, labs |

| Wide Temperature Range | Performs from -200°C to +260°C | Cryogenic, high-heat, and outdoor applications |

| Excellent Electrical Insulation | High dielectric strength prevents current flow | Electrical equipment, sensitive instruments |

| Lightweight & Compliant | Easy to machine, FDA-approved, RoHS compliant | Food & medical equipment, weight-sensitive designs |

Need a high-performance PTFE bush for your specific application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom bushes—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require the pure chemical resistance of virgin PTFE, the enhanced wear resistance of carbon-filled PTFE, or the superior dimensional stability of glass-filled PTFE, we provide custom fabrication from prototypes to high-volume orders.

Let us help you solve your unique challenges with a material engineered for extreme environments. Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts