At their core, the key advantages of PTFE shaft seals are their exceptional chemical resistance, high-temperature tolerance, and an inherently low coefficient of friction. These properties allow them to operate reliably in extreme industrial environments where traditional elastomeric seals would quickly fail.

PTFE seals are not merely an alternative to conventional seals; they are an engineered solution designed specifically for demanding applications involving aggressive chemicals, high temperatures, high pressures, or dry-running conditions.

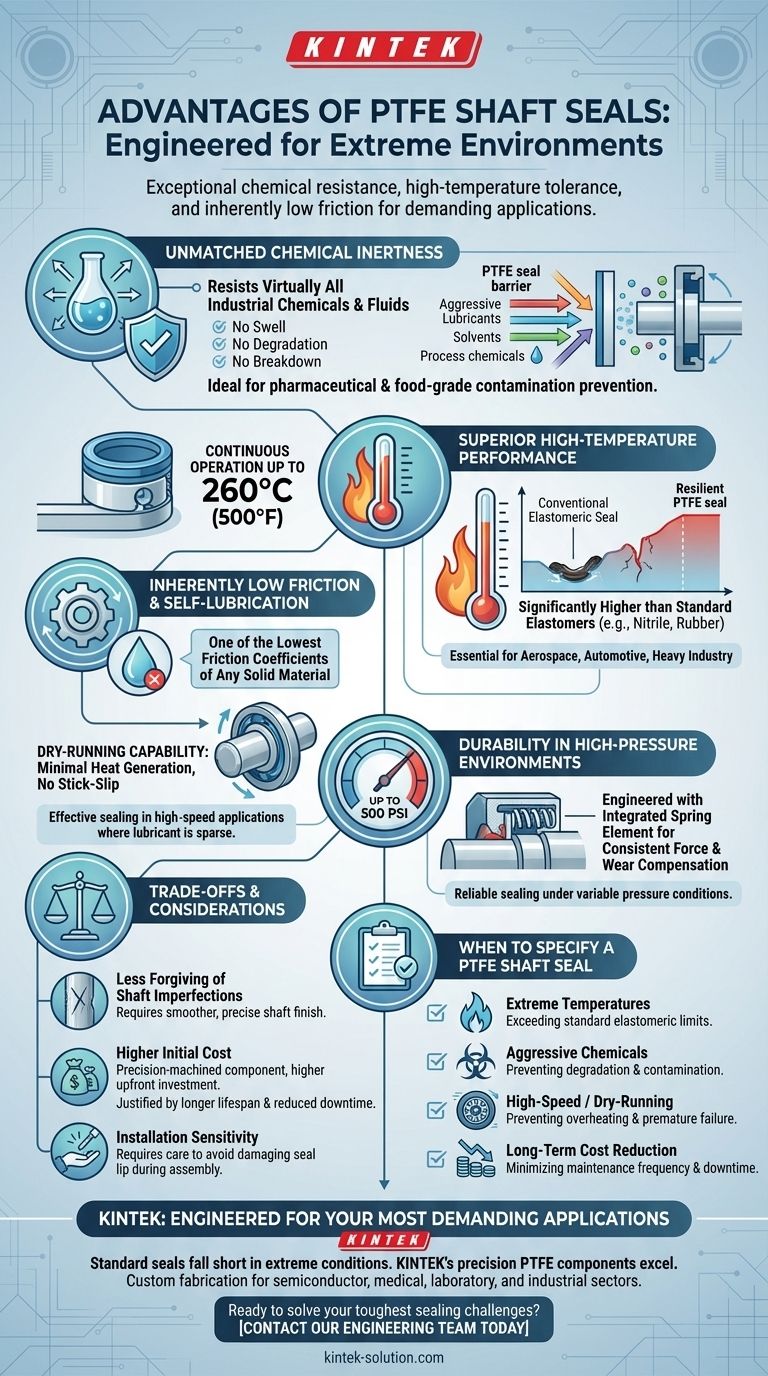

The Core Strengths of PTFE Sealing Technology

The unique material properties of Polytetrafluoroethylene (PTFE) are what set these seals apart. They solve critical engineering challenges that are beyond the capabilities of standard rubber or nitrile seals.

Unmatched Chemical Inertness

PTFE is inert to almost all industrial chemicals and fluids. This means the seal will not swell, degrade, or break down when exposed to aggressive lubricants, solvents, or process chemicals.

This property is critical for ensuring seal integrity and preventing contamination of the system media, making it ideal for pharmaceutical or food-grade applications.

Superior High-Temperature Performance

PTFE seals can operate continuously at temperatures up to 260°C (500°F). This is significantly higher than most elastomeric materials, which would become brittle or melt under similar conditions.

This high-temperature capability makes them essential for equipment in aerospace, automotive, and heavy industrial settings where high operational heat is a given.

Inherently Low Friction and Self-Lubrication

PTFE has one of the lowest friction coefficients of any solid material. This allows it to run with minimal heat generation and torque loss, even without lubrication.

This "dry-running" capability is a major advantage, as it prevents the "stick-slip" behavior common in other seals and allows for effective sealing in high-speed rotating applications where lubricant may be sparse.

Durability in High-Pressure Environments

Engineered PTFE seals are designed to withstand high pressures, with some capable of handling up to 500 psi.

An integrated spring element often provides a consistent force, ensuring the seal lip remains in constant contact with the shaft and compensates for wear, even under variable pressure conditions.

Understanding the Trade-offs

While powerful, PTFE seals are a specialized component, and their selection requires an understanding of their limitations compared to more flexible elastomeric seals.

Less Forgiving of Shaft Imperfections

Because PTFE is a harder, less compliant material than rubber, it requires a smoother and more precise shaft surface finish to create a reliable seal. Minor scratches or imperfections that a flexible rubber seal might conform to can create a leak path for a PTFE seal.

Higher Initial Cost

PTFE seals are typically precision-machined components, not mass-molded. This results in a higher upfront cost compared to standard elastomeric seals.

However, this cost is often justified by a significantly longer lifespan and reduced equipment downtime, leading to a lower total cost of ownership in demanding applications.

Installation Sensitivity

The relative stiffness of PTFE means that installation requires more care. Special tools or procedures may be necessary to avoid damaging the precision-machined seal lip during assembly.

When to Specify a PTFE Shaft Seal

Choosing the right seal depends entirely on the operational demands of your equipment.

- If your primary focus is operating in extreme temperatures: PTFE is the default choice when service temperatures exceed the limits of conventional elastomeric seals.

- If your primary focus is compatibility with aggressive chemicals: PTFE's chemical inertness is non-negotiable for preventing seal degradation and fluid contamination.

- If your primary focus is high-speed or dry-running applications: PTFE's self-lubricating, low-friction nature is essential for preventing overheating and premature failure.

- If your primary focus is minimizing long-term operating costs in harsh environments: The durability of PTFE provides a superior return on investment by drastically reducing maintenance frequency and downtime.

Ultimately, specifying a PTFE seal is a strategic decision to engineer reliability into equipment that operates beyond standard conditions.

Summary Table:

| Key Advantage | Key Benefit |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, preventing degradation and contamination. |

| High-Temperature Performance | Operates continuously up to 260°C (500°F), far exceeding standard elastomers. |

| Low Friction & Self-Lubrication | Enables dry-running and high-speed operation with minimal heat generation. |

| High-Pressure Durability | Engineered to withstand pressures up to 500 psi with consistent sealing force. |

Engineered for Your Most Demanding Applications

When your equipment operates in extreme conditions—high temperatures, aggressive chemicals, or high-speed rotations—standard seals fall short. That's where KINTEK's precision PTFE components excel.

We manufacture high-performance PTFE shaft seals, liners, and labware specifically for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication process, from prototypes to high-volume orders, ensures you get a sealing solution engineered for reliability and a lower total cost of ownership.

Ready to solve your toughest sealing challenges? Contact our engineering team today to discuss your application requirements.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the main chemical resistance properties of PTFE-coated O-rings? Uncover the True Role of the Coating

- What are the advantages of PTFE-based seals? Unmatched Performance in Extreme Conditions