Yes, PTFE bellows are highly customizable to meet precise operational demands. Customization extends beyond simple dimensions like size and length to include critical performance characteristics such as material composition, wall thickness, and the specific geometry of the folds, each of which is engineered for a different purpose.

The key to customizing a PTFE bellow is understanding that you are not just altering its shape, but fundamentally tuning its mechanical performance—balancing flexibility, pressure resistance, and durability to match the exact needs of your system.

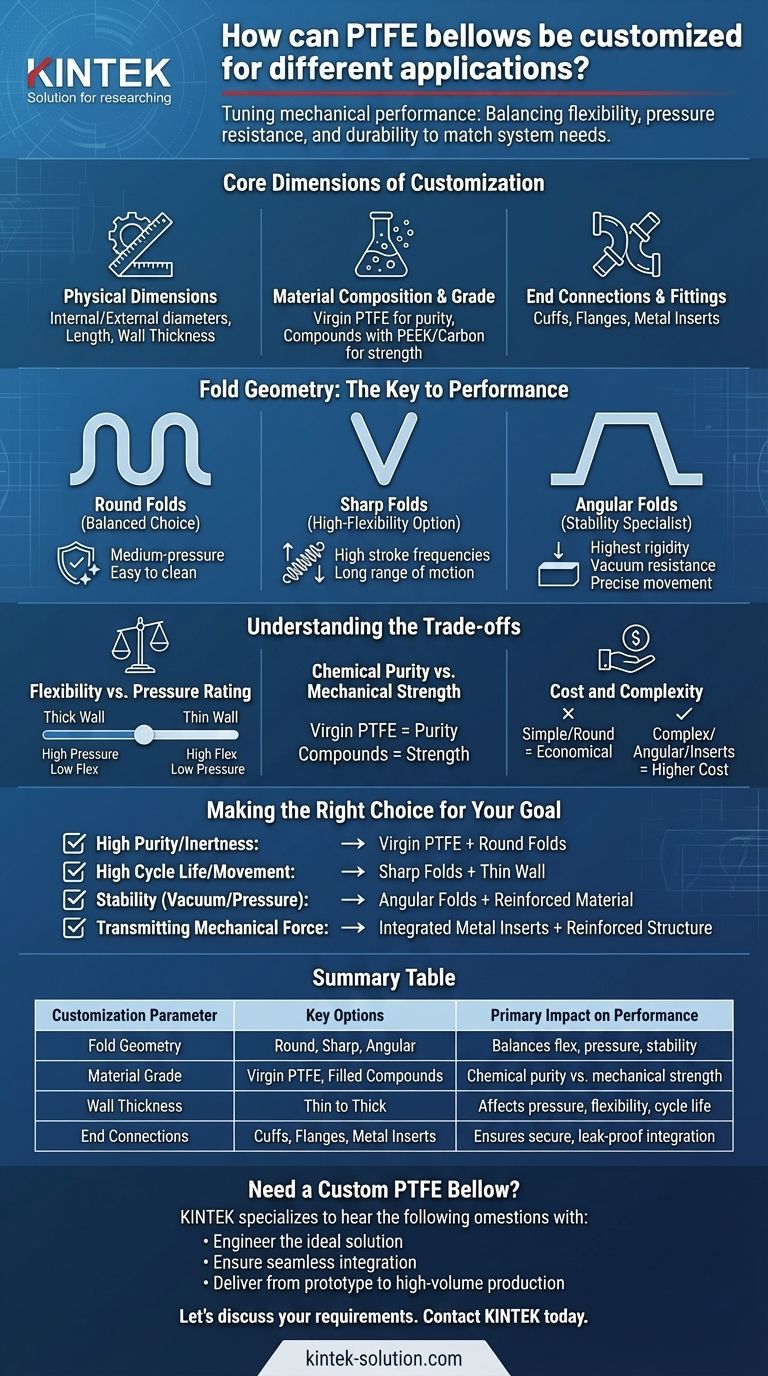

The Core Dimensions of Customization

A truly optimized bellow is specified across several key parameters. Each choice directly impacts how the bellow will perform under stress, chemical exposure, and movement.

Physical Dimensions

The most basic form of customization involves tailoring the physical size and shape. These parameters determine how the bellow fits and moves within your assembly.

Key specifications include internal and external diameters, overall length (both compressed and extended), and wall thickness. Thicker walls, for example, increase pressure and vacuum resistance but may reduce flexibility and cycle life.

Material Composition and Grade

While "PTFE" is the base material, its properties can be enhanced for specific challenges.

You can specify virgin PTFE for maximum chemical inertness and purity, which is critical in semiconductor or pharmaceutical applications. Alternatively, you can opt for a PTFE compound, where materials like PEEK or carbon are added to improve mechanical strength, rigidity, and wear resistance.

End Connections and Fittings

A bellow is useless if it cannot be securely integrated into your system.

End connections can be customized as simple cuffs for hose clamps, molded flanges with bolt patterns, or even have integrated metal inserts for high-force applications or threaded connections. This ensures a leak-proof and mechanically sound interface with your existing equipment.

Fold Geometry: The Key to Performance

The shape of the bellow's convolutions is the most critical factor in tuning its performance. Each fold profile is engineered to prioritize a specific capability.

Round Folds: The Balanced Choice

These bellows feature smooth, U-shaped convolutions. This design is often preferred for medium-pressure applications and is notably easy to clean, making it a common choice in food, beverage, and pharmaceutical processing.

Sharp Folds: The High-Flexibility Option

Characterized by deep, V-shaped convolutions, this design maximizes axial movement for a given length. It is the ideal choice for low-pressure systems that require high stroke frequencies or a long range of motion, such as in dosing pumps or instrument actuators.

Angular Folds: The Stability Specialist

With a trapezoidal or squared-off fold profile, these bellows offer the highest rigidity and wall stability. This makes them exceptionally resistant to collapsing under vacuum and suitable for applications requiring precise, stable movement without lateral wobble.

Understanding the Trade-offs

Customization is a process of balancing competing requirements. Understanding these trade-offs is essential for making an informed decision.

Flexibility vs. Pressure Rating

There is a direct trade-off between a bellow's ability to flex and its ability to withstand pressure. Increasing wall thickness or using more rigid angular folds will improve pressure/vacuum rating but will inherently reduce flexibility and shorten cycle life.

Chemical Purity vs. Mechanical Strength

Virgin PTFE offers the ultimate resistance to nearly all chemicals. However, introducing fillers to create a PTFE compound (e.g., with PEEK) enhances mechanical properties like creep resistance and hardness. This can be a critical advantage, but you must verify the chemical compatibility of the filler material with your specific media.

Cost and Complexity

As a rule, increased complexity drives up cost. A simple, round-fold bellow made from virgin PTFE will be more economical than a reinforced, angular-fold bellow with custom-molded metal inserts. It is crucial to specify only the features your application truly requires.

Making the Right Choice for Your Goal

Use your primary operational need to guide your customization choices.

- If your primary focus is high purity and chemical inertness: Specify a virgin PTFE bellow, likely with round folds for superior cleanability.

- If your primary focus is high cycle life and maximum movement: Choose a sharp-fold design engineered with the minimum wall thickness required for your pressure rating.

- If your primary focus is stability under vacuum or pressure: Select an angular-fold design and consider reinforcing the material with a suitable filler.

- If your primary focus is transmitting mechanical force: Work with a manufacturer to design a bellow with integrated metal inserts or a reinforced structure.

By understanding these design levers, you can engineer a PTFE bellow that functions as a perfectly integrated component of your system.

Summary Table:

| Customization Parameter | Key Options | Primary Impact on Performance |

|---|---|---|

| Fold Geometry | Round, Sharp, Angular | Balances flexibility, pressure resistance, and stability |

| Material Grade | Virgin PTFE, Filled Compounds | Determines chemical purity vs. mechanical strength |

| Wall Thickness | Thin to Thick | Affects pressure rating, flexibility, and cycle life |

| End Connections | Cuffs, Flanges, Metal Inserts | Ensures secure, leak-proof integration into the system |

Need a Custom PTFE Bellow for Your Critical Application?

KINTEK specializes in the precision manufacturing of custom PTFE components, including bellows, for the semiconductor, medical, laboratory, and industrial sectors. We understand that your application's success depends on a perfectly tuned component.

We partner with you to:

- Engineer the ideal solution by selecting the right fold geometry, material grade, and wall thickness to balance flexibility, pressure resistance, and chemical compatibility.

- Ensure seamless integration with custom end connections like flanges or metal inserts for a secure, leak-proof fit.

- Deliver from prototype to high-volume production with a focus on precision and durability.

Let's discuss your requirements and engineer a bellow that performs as an integral part of your system.

Contact KINTEK today for a consultation

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the advantages of Polytetrafluoroethylene (PTFE) with Graphite Fill? Enhance Wear and Friction Performance

- What are the components of an assembly PTFE sliding bearing pad? A Guide to the Engineered System

- Why are PTFE ring gaskets still preferred despite their disadvantages? For Unmatched Chemical & Thermal Resistance

- How should cooling be managed during Teflon machining? Prevent Warping & Ensure Precision

- How does the lining of PTFE/PFA lined ball valves provide corrosion resistance? A Guide to Superior Chemical Handling

- What are the installation methods for PTFE slide bearings? Select the Right Method for Your Structure

- What are the properties of standard Polytetrafluoroethylene (PTFE)? The Ultimate Guide to Its Strengths & Limitations

- What raw material is used to manufacture PTFE spacers? Discover the Power of Teflon for High-Performance Components