In short, PTFE ring gaskets are preferred in specific, demanding situations where their extraordinary chemical inertness and temperature resistance are non-negotiable. For applications involving aggressive chemicals or extreme heat, these properties are critical and outweigh the material's mechanical disadvantages, such as its tendency to deform under pressure.

The decision to use a PTFE gasket is a calculated trade-off. You are choosing its unparalleled environmental resilience over the superior mechanical sealing performance and lower cost of traditional materials like rubber.

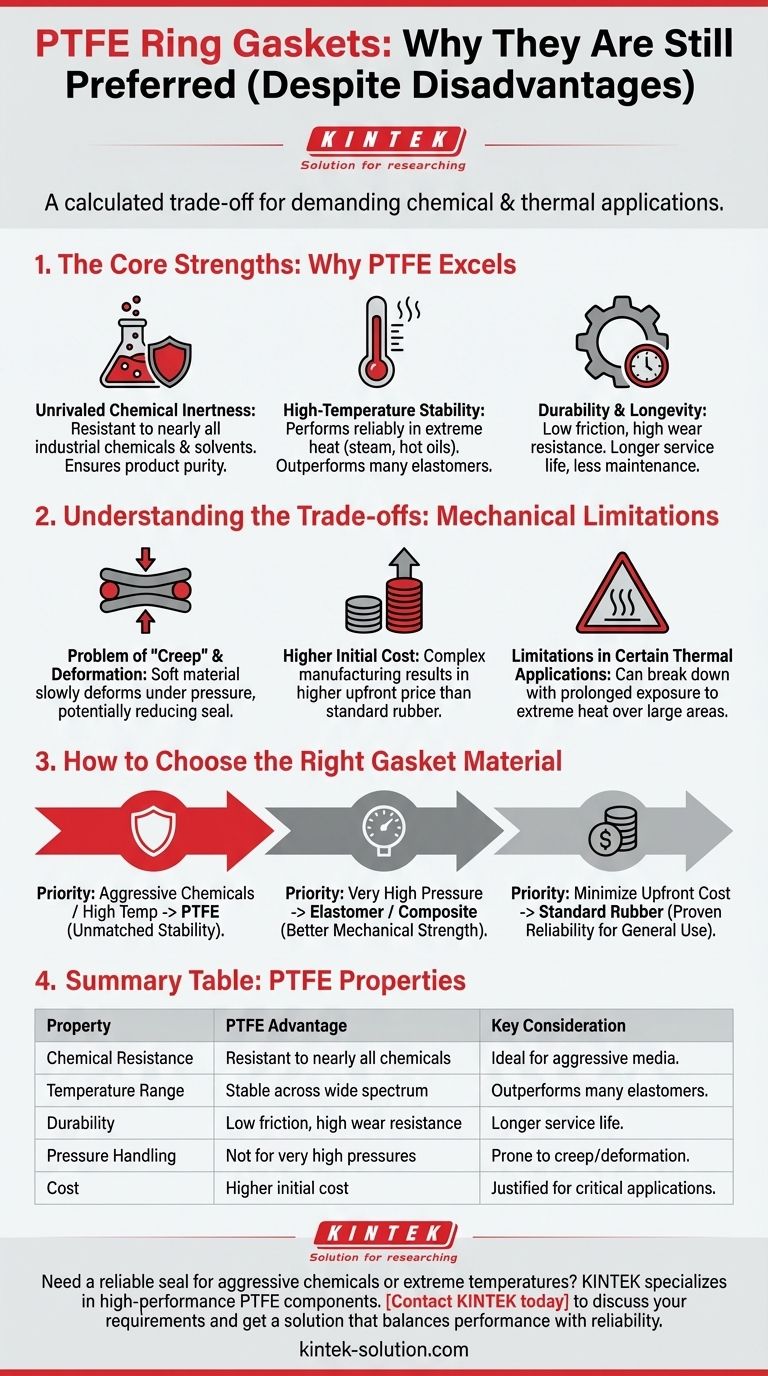

The Core Strengths: Why PTFE Excels in Harsh Environments

PTFE, also known by the trade name Teflon, possesses a unique combination of properties that make it the default choice for applications where other materials would quickly fail.

Unrivaled Chemical Inertness

PTFE is resistant to nearly all industrial chemicals and solvents. This makes it indispensable in chemical processing, pharmaceuticals, and food and beverage industries.

Where a standard rubber gasket would degrade or contaminate the process media, PTFE remains completely stable, ensuring both a reliable seal and product purity.

High-Temperature Stability

The material can withstand a wide range of temperatures, performing reliably where many elastomers would become brittle or melt.

This thermal stability is crucial for applications involving steam, hot oils, or other high-temperature industrial processes.

Durability and Longevity

PTFE has a very low coefficient of friction, which contributes to high surface wear resistance.

This, combined with its resistance to environmental degradation, results in a longer service life, reducing the frequency of maintenance and replacement in critical systems.

Understanding the Trade-offs: The Mechanical Limitations of PTFE

Despite its strengths, PTFE is not a universal solution. Its physical properties introduce clear limitations that must be understood to prevent seal failure.

The Problem of "Creep" and Deformation

The primary disadvantage of PTFE is its softness and lack of "memory" or elasticity. Under sustained pressure from flange bolts, the material will slowly deform, a phenomenon known as creep.

This deformation can reduce the sealing pressure over time, potentially leading to leaks. It makes PTFE unsuitable for very high-pressure applications unless incorporated into a specially engineered gasket design.

Higher Initial Cost

The manufacturing process for PTFE is more complex and costly than for common rubber materials.

This results in a higher upfront price for PTFE gaskets, which may not be justifiable for standard, non-critical applications where a less expensive material would suffice.

Limitations in Certain Thermal Applications

While generally excellent at high temperatures, pure PTFE can break down if exposed to extreme heat across a very large surface area for prolonged periods.

This is a specific limitation that requires careful consideration during the engineering phase for large-scale, high-heat equipment.

How to Choose the Right Gasket Material

Selecting the correct gasket requires you to prioritize your application's most critical demand: environmental resistance or mechanical performance.

- If your primary focus is sealing aggressive chemicals or operating at high temperatures: PTFE is almost certainly the correct choice, as its chemical and thermal stability are unmatched.

- If your primary focus is containing very high pressures in a standard environment: A traditional elastomer or a composite gasket with better mechanical strength and elasticity is likely a more reliable and cost-effective option.

- If your primary focus is minimizing upfront cost for a general-purpose application: Standard rubber gaskets offer proven reliability at a much lower price point.

Ultimately, understanding the fundamental trade-offs of PTFE allows you to leverage its exceptional strengths precisely where they are most needed.

Summary Table:

| Property | PTFE Gasket Advantage | Key Consideration |

|---|---|---|

| Chemical Resistance | Resistant to nearly all chemicals and solvents. | Ideal for aggressive media. |

| Temperature Range | Stable across a wide temperature spectrum. | Outperforms many elastomers. |

| Durability | Low friction and high wear resistance. | Longer service life. |

| Pressure Handling | Not suitable for very high pressures. | Prone to creep/deformation. |

| Cost | Higher initial cost. | Justified for critical applications. |

Need a reliable seal for aggressive chemicals or extreme temperatures?

KINTEK specializes in manufacturing high-performance PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that delivers unmatched environmental resilience for your most demanding applications.

Contact KINTEK today to discuss your specific requirements and get a solution that balances performance with reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some key applications of low-friction PTFE in bearings and bushings? Achieve Maintenance-Free Performance

- What are the primary applications of PTFE Teflon washers in plumbing? Ensure Leak-Proof Seals in Harsh Environments

- How does chemical resistance benefit PTFE washers? Ensure Unmatched Reliability in Harsh Environments

- What is the typical temperature range for PTFE diaphragms? Key Factors for Optimal Performance

- What are the technical limitations of PTFE gaskets? Navigating Creep, Cold Flow, and Sealing Challenges

- What are the key characteristics of PTFE rotary seals? Superior Performance for Extreme Conditions

- What temperature range can PTFE sheets withstand? From -200°C to +260°C for Extreme Applications

- What are the main advantages of PTFE lined butterfly valves in industrial applications? Achieve Superior Corrosion Resistance & Cost Savings