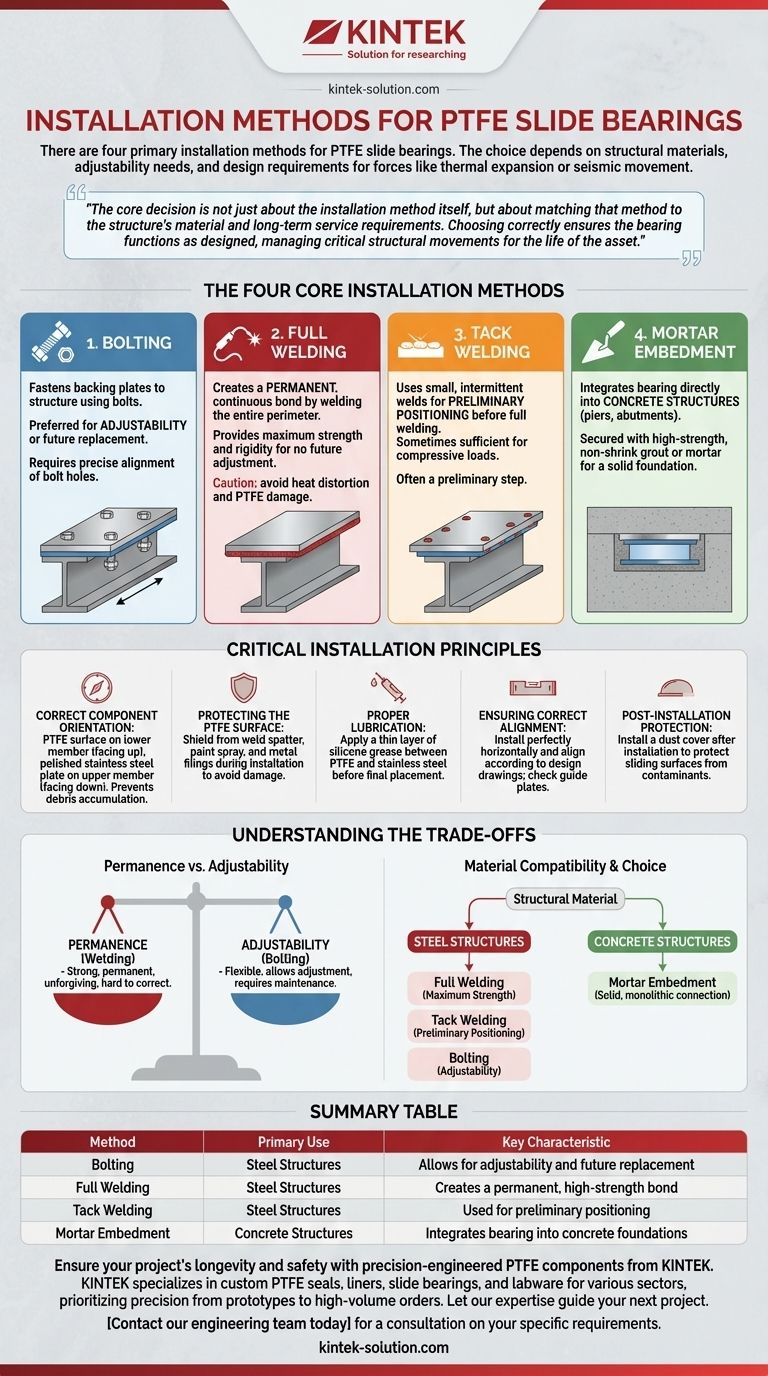

There are four primary installation methods for PTFE slide bearings. These are full welding, tack welding, bolting, and mortar embedment. The specific method chosen is dictated by the structural materials, the need for future adjustability, and the design requirements for handling forces like thermal expansion or seismic movement.

The core decision is not just about the installation method itself, but about matching that method to the structure's material and long-term service requirements. Choosing correctly ensures the bearing functions as designed, managing critical structural movements for the life of the asset.

The Four Core Installation Methods

Each installation method serves a distinct purpose, primarily determined by whether the bearing is being attached to steel or integrated into concrete.

Bolting

Bolting involves fastening the bearing's backing plates to the structure using bolts. This is the preferred method when adjustability or future replacement is a priority.

It requires precise alignment of bolt holes between the bearing plate and the structural member.

Full Welding

This method creates a permanent, continuous bond by welding the entire perimeter of the bearing's steel backing plate directly to a steel structural member.

Full welding provides maximum strength and rigidity, making it ideal for applications where no future adjustment is anticipated. Care must be taken to avoid heat distortion of the plate and damage to the PTFE.

Tack Welding

Tack welding uses small, intermittent welds to secure the bearing's backing plate. It is often used for preliminary positioning before executing a full weld.

In some designs, tack welding may be sufficient for the final installation if the primary forces are compressive and shear loads are low.

Mortar Embedment

Mortar embedment is used to integrate the bearing directly into concrete structures, such as piers or abutments.

The bottom plate of the bearing is placed in a recess and secured with high-strength, non-shrink grout or mortar, creating a solid, load-bearing foundation.

Critical Installation Principles

Proper installation is more than just fixing the bearing in place. Adhering to fundamental principles is essential for the bearing's performance and longevity.

Correct Component Orientation

The assembly must be oriented correctly to function. The PTFE surface should be installed on the lower member, facing up.

The corresponding upper member must have a polished stainless steel plate facing down to slide against the PTFE. This configuration prevents debris from accumulating on the sliding surface.

Protecting the PTFE Surface

The low-friction PTFE surface is sensitive and must be protected at all times during installation.

Shield the surface from weld spatter, paint spray, and metal filings. Any damage or contamination can compromise the bearing's performance.

Proper Lubrication

Before the final components are placed, a thin, even layer of silicone grease should be applied between the PTFE and the stainless steel plate. This lubricant reduces the initial coefficient of friction.

Ensuring Correct Alignment

The bearing must be installed perfectly horizontally and aligned according to the design drawings. Many bearings include guide plates or stops that indicate the required direction of movement.

Post-Installation Protection

After installation is complete and the structure is in place, a dust cover should be installed. This protects the sliding surfaces from environmental contaminants throughout the life of the structure.

Understanding the Trade-offs

The choice of installation method involves balancing permanence, material compatibility, and on-site practicalities.

Permanence vs. Adjustability

Welding creates a permanent connection. This is strong but unforgiving; mistakes are difficult to correct, and replacement is a major undertaking.

Bolting allows for adjustment, shimming, and replacement. This flexibility is valuable but introduces the need for proper bolt tensioning and periodic inspection.

Material Compatibility

The choice is often made for you by the structural materials. Welding is exclusively for steel-to-steel connections.

Mortar embedment is the primary method for concrete supports. It ensures the load from the bearing is transferred smoothly into the concrete foundation.

Making the Right Choice for Your Structure

Selecting the correct installation method is critical for ensuring the bearing performs as intended, managing structural forces effectively and reliably.

- If your primary focus is a permanent bond on a steel structure: Use full welding for maximum strength and rigidity.

- If your primary focus is future adjustability or ease of replacement: Use bolting, as it allows for removal and reinstallation.

- If your primary focus is integrating the bearing with a concrete pier or abutment: Use mortar embedment to create a solid, monolithic connection.

- If your primary focus is temporarily securing a bearing for final placement: Use tack welding as a preliminary step before full welding.

Ultimately, correct installation transforms a simple component into a critical element that ensures the structure's long-term health and safety.

Summary Table:

| Method | Primary Use | Key Characteristic |

|---|---|---|

| Bolting | Steel Structures | Allows for adjustability and future replacement |

| Full Welding | Steel Structures | Creates a permanent, high-strength bond |

| Tack Welding | Steel Structures | Used for preliminary positioning |

| Mortar Embedment | Concrete Structures | Integrates bearing into concrete foundations |

Ensure your project's longevity and safety with precision-engineered PTFE components from KINTEK.

Choosing the right installation method is critical, but it starts with a high-quality bearing designed for your specific application. KINTEK specializes in manufacturing custom PTFE seals, liners, slide bearings, and labware for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision in every component, from prototypes to high-volume orders.

Let our expertise guide your next project. Contact our engineering team today for a consultation on your specific requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications